Description

1. Technical Specifications

| Non. | Article | Unité | Spécification |

|---|---|---|---|

| 1 | Nom du modèle | / | 9GD-2.5 Single Blade Mower |

| 2 | Type d'attelage | / | Tirage latéral |

| 3 | Cutter Mechanism Type | / | Reciprocating |

| 4 | Largeur de coupe | m | 2.5 |

| 5 | Puissance requise | kW | 15–35 |

| 6 | Operating Speed Range | km/h | 6–10 |

| 7 | Nombre de lames de coupe | pieces | 34 |

| 8 | Dimensions extérieures (L × l × H) | mm | 2000 × 4300 × 950 |

| 9 | Vitesse de l'arbre de sortie | r/min | 540 |

| 10 | Hauteur de coupe moyenne | mm | 50–70 |

| 11 | Productivité | hm²/h | 2.0–3.0 |

| 12 | Nombre d'opérateurs | people | 1 |

| 13 | Poids structurel | kg | 490 |

2. Product Overview and Market Value Proposition

Against the backdrop of continuous advancements in modern agriculture, particularly in the field of forage crop harvesting in countries like South Korea, the United States, and Germany, the demand for efficient, low-maintenance, and cost-effective machinery has reached unprecedented levels. The 9GD-2.5 towed single-blade mower (upgraded version) is designed to meet these demands. Unlike standard mowers, this upgraded version features a towed design and can be driven by wheeled tractors with a power output of 15-35 kW (20-50 horsepower).

It is specifically optimized for harvesting natural grasses, alfalfa, ryegrass, and reeds. The core value of this machine lies in its robust and durable construction and ease of operation. The upgraded version is equipped with an advanced hydraulic system for controlling the raising and lowering of the cutting blade, significantly reducing manual labor and improving operational safety. For farmers in regions like Jeollanam-do or Chungcheong-do in South Korea, who prioritize efficiency and maximizing yield per hectare, this mower ensures a clean and precise cut, promoting faster plant regeneration. Its reciprocating cutting method minimizes crop damage compared to rotary mowers, thus preserving the nutritional value of the leaves, which is crucial for producing high-quality livestock feed.

3. Working Principle and Engineering Excellence

4. Material Science and Manufacturing Standards

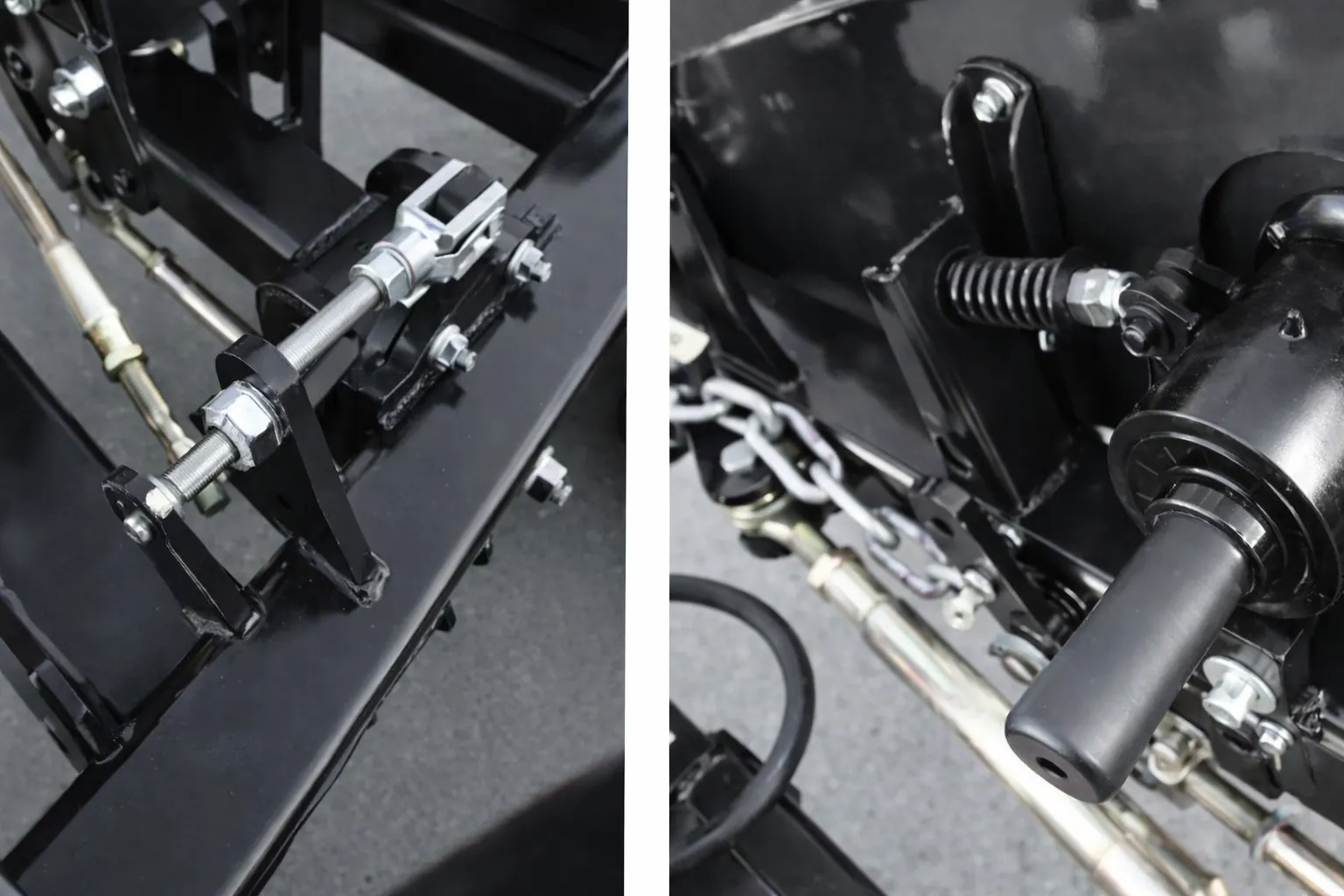

At EVER-POWER, we understand that agricultural machinery must withstand harsh environments and constant stress. The 9GD-2.5 towed single-blade mower (upgraded version) is manufactured with high-grade metal materials to ensure durability and reliable performance. The blades are made from 65Mn spring steel or special alloy tool steel and undergo a rigorous heat treatment process, including quenching and tempering. This results in a blade hardness typically reaching HRC 50-55, providing excellent wear resistance while maintaining sufficient toughness to prevent brittle fracture even when encountering small obstacles.

The main frame and drawbar are constructed from high-strength Q345 structural steel, forming a robust framework that effectively resists twisting and deformation, even when operating on rough terrain. Hydraulic components, including the cylinder used to lift the cutting mechanism, utilize high-pressure seals and precision-machined pistons to prevent leaks and ensure smooth operation over thousands of cycles.

Furthermore, the surface treatment employs advanced electrostatic powder coating technology, offering superior corrosion resistance compared to traditional wet paints. This is crucial for machinery frequently exposed to humid environments and plant sap.

5. Application Scenarios and Usage Guidelines

The 9GD-2.5 towed single-blade mower (upgraded version) offers versatile functionality, making it an essential piece of equipment in various agricultural environments. Its primary use is harvesting cultivated forage crops and natural grasslands. This mower is ideal for Korean dairy farms growing Italian ryegrass or alfalfa, as it handles the crops gently, maximizing leaf retention, which is where the majority of the protein is stored.

Due to its 2.5-meter-wide cutting width, it is also well-suited for harvesting reeds at the edges of wetlands (provided the ground is firm enough for the tractor to traverse). The machine features a side-pull design, allowing the tractor to travel on already mowed stubble or unmowed areas without crushing the crops about to be harvested.

However, for safe operation, some limitations must be noted: this mower is not suitable for muddy rice paddies, heavily waterlogged wetlands where the tractor might sink, dense forests, or fields with many rocks or tall, thick grass. Operating in these environments may damage the reciprocating blades. The ideal terrain is flat to moderately sloped pastureland. The machine’s low power requirement (minimum of only 20 horsepower) makes it suitable for both small family farms and large cooperatives, perfectly fitting the “small farm, high efficiency” model prevalent in many Asian and European markets.

6. Global Regulations and Compliance (Korea Focus)

Navigating the regulatory landscape is critical for the import and operation of agricultural machinery. For the South Korean market, the 9GD-2.5 Trailed Single Knife Mower aligns with the safety and performance standards set by the Korea Agricultural Machinery Industry Cooperative (KAMICO) and the Rural Development Administration (RDA). While specific certification requirements like the FACTS (Foundation of Agri. Tech. Commercialization & Transfer) testing may apply for subsidies, EVER-POWER machines are designed to meet ISO 4254-1 (Agricultural machinery safety) standards.

In South Korea, regulations regarding machinery subsidies often require specific safety guards and PTO shielding, which this upgraded version includes. Globally, the machine complies with the GB/T 10940-2008 standard for “Reciprocating Mowers” in China, which shares similarities with ISO standards regarding cutter bar performance and safety distances. For European markets, the machinery adheres to the Machinery Directive 2006/42/EC, ensuring CE compliance, particularly regarding the guarding of moving parts and hydraulic line safety. Understanding these regulations is vital for importers. For instance, in Brazil (NR-12 regulations) and the US (ASABE/ANSI standards), specific warning decals and operator manuals are required, which EVER-POWER provides. This adherence to legal frameworks ensures that our partners can import and distribute our mowers with confidence, minimizing legal risks and ensuring user safety.

7. Industry Trend Analysis: The Shift to Efficient Forage

The agricultural machinery market in South Korea and globally is witnessing a distinct trend towards “Smart & Efficient” farming. With the aging population of farmers in Korea, there is a strong push away from labor-intensive manual harvesting towards mechanized solutions that do not require massive, expensive tractors. The 9GD-2.5 occupies a strategic sweet spot in this trend. While high-speed disc mowers are popular, they require higher horsepower and fuel consumption. The reciprocating mower trend is seeing a resurgence due to rising fuel costs and the need for higher quality fodder; the scissor-cut preserves the plant structure better than the impact-cut of disc mowers, leading to faster drying times and better feed quality. Furthermore, the trend towards “light-duty footprint” machinery means farmers prefer lighter equipment like the 9GD-2.5 (490kg) to reduce soil compaction, preserving the long-term health of the pasture. EVER-POWER aligns with this trend by offering an “Upgrade Version” that integrates hydraulic ease-of-use with the traditional benefits of sickle bar mowing.

8. Customer Success Story

9. Le système de garantie et d'assistance après-vente de la presse à balles rondes 9YG-1.25A.

1. Réparation et remplacement de pièces détachées.

2. Chaque produit est livré avec un manuel d'utilisation gratuit.

3. Service après-vente et garantie/maintenance.

4. Produits livrés dans le monde entier.

5. Des équipes linguistiques professionnelles communiquent pour comprendre vos besoins.

6. Formation produit.

7. Chaque année, pendant la saison de la coupe de l'herbe, nous effectuons des suivis et des études de marché auprès de chaque éleveur qui a acheté et utilisé nos produits, et nous fournissons une formation technique aux nouveaux utilisateurs.

10. Le système de garantie et d'assistance après-vente de la presse à balles rondes 9YG-1.25A.

Nous avons équipé nos bases de production modernes d'équipements de pointe, tels que :

·Certification du système de gestion de la qualité ISO9001

Machines de découpe laser CNC

Systèmes de découpe laser et plasma

· Chaînes de montage automatisées

Systèmes de lignes de production par pulvérisation électrostatique

Logiciels pour usine numérique et industrie

• Stations d'essai au dynamomètre, etc.

À propos de nous

11. Composants associés.

Pour ceux qui recherchent un « collier d'arbre pour presses à balles rondes » ou un « collier d'arbre de rechange pour presse à foin », notre solution offre la précision et la fiabilité nécessaires à une agriculture durable.

Nous proposons également des pièces détachées, notamment Arbre de prise de force et boîte de vitesses du tracteur, chaîne et pignon d'entraînement, poulie et galet, roulements et collier d'arbre de ramassage, arbre et support de ramasseuse à foin, patins et plaques d'abrasion, dents et ressorts de ramasseuse à foin.

Contactez-nous, et nous vous enverrons un rapport détaillé PDF des pièces de rechange disponibles.

12. Foire aux questions (FAQ)

Q1. How does the price of the 9GD-2.5 trailed mower compare to a disc mower?

A1. The 9GD-2.5 trailed single blade lawn mower for sale is generally significantly more affordable than disc mowers of similar width, often costing 30-40% less, making it a budget-friendly option for cost-conscious farmers.

Q2. What is the minimum horsepower required to operate this 2.5m mower effectively?

A2. This mower is designed for efficiency; you can operate it effectively with a tractor as small as 20HP (15KW), though we recommend 30-50HP for optimal performance on slopes.

Q3. Where can I find spare parts for the cutting blade if they wear out in South Korea?

A3. We use standard knife sections compatible with major international standards. We can supply a spare parts kit with your order, or you can source standard sickle sections from local agricultural suppliers in Korea.

Q4. Is this mower suitable for harvesting rice straw in wet paddy fields?

A4. No, the 9GD-2.5 is designed for dry pastures and natural grass. It is not suitable for wet, muddy paddy fields or areas with significant water, as this can clog the reciprocating mechanism.

Q5. How do I connect the hydraulic lift system to my tractor?

A5. The upgrade version comes with standard hydraulic hoses and quick-couplers. You simply plug these into your tractor’s rear hydraulic remotes to control the lifting of the cutter bar from the cabin.

Q6. Can this machine handle rocky terrain without breaking the blades?

A6. While it has a floating mechanism to handle uneven ground, reciprocating mowers are sensitive to rocks. We strictly advise removing large stones from the field before operation to prevent damage to the knife guards.

Q7. What is the shipping volume if I want to order a container load for wholesale?

A7. The machine has dimensions of 2000×4300×950mm in working state but can be partially disassembled for shipping. Please contact our sales team for exact packing dimensions and container loading quantities.

Q8. Does EVER-POWER offer customization for the paint color to match our dealership brand?

A8. Yes, as an OEM manufacturer, we can customize the paint color and branding stickers to match your dealership’s requirements for bulk orders.

Q9. How often do I need to sharpen or replace the moving blades?

A9. This depends on usage intensity and crop type. Generally, blades should be inspected daily. Sharpening may be needed every 20-30 hours of operation, and replacement is straightforward when they become serrated or worn down.

Q10. Which payment terms do you accept for international shipments to Korea or Germany?

A10. We typically accept T/T (Telegraphic Transfer) or L/C (Letter of Credit) at sight. We can provide FOB, CIF, or DDP quotes depending on your logistical preference.

Éditeur : PXY