विवरण

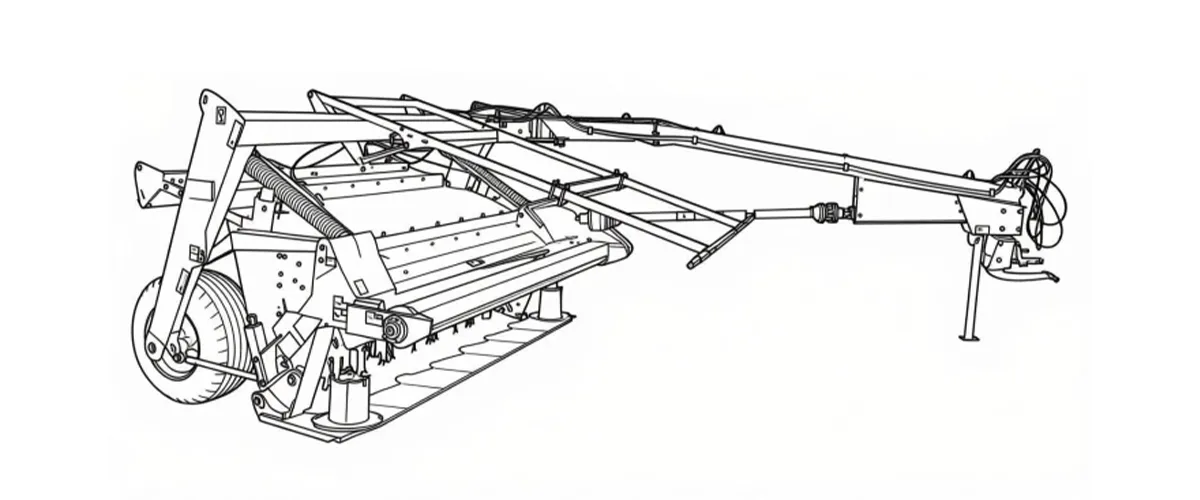

1. Technical Specifications: 9GQY-3.2 Series

| नहीं। | वस्तु | इकाई | विनिर्देश |

|---|---|---|---|

| 1 | मॉडल नाम | / | 9GQY-3.2 Type Round Baler |

| 2 | हिच टाइप | / | Side Pull |

| 3 | Cutting Width | एम | 3.2 |

| 4 | Cutter Structure Type | / | Rotary |

| 5 | Number of Blades | पीसी | 8 |

| 6 | Press Type | / | Impact Disc Press |

| 7 | Pickup Width Range | एम | 0.8-2.2 |

| 8 | आवश्यक शक्ति | KW/hp | ≥80.88/110 |

| 9 | Working Speed Range | किमी/घंटा | 6–15 |

| 10 | आउटपुट शाफ्ट गति | आर/मिनट | 540-1000 |

| 11 | Number of Cutter Blades | पीसी | 16 |

| 12 | बाह्य आयाम (लंबाई × चौड़ाई × ऊंचाई) | मिमी | 6750 × 3500 × 2000 |

| 13 | Average Cutting Height | मिमी | ≥50 |

| 14 | Number of Operators | person | 1 |

| 15 | संरचनात्मक भार | किलोग्राम | 2185 |

2. Key Facts & Capabilities

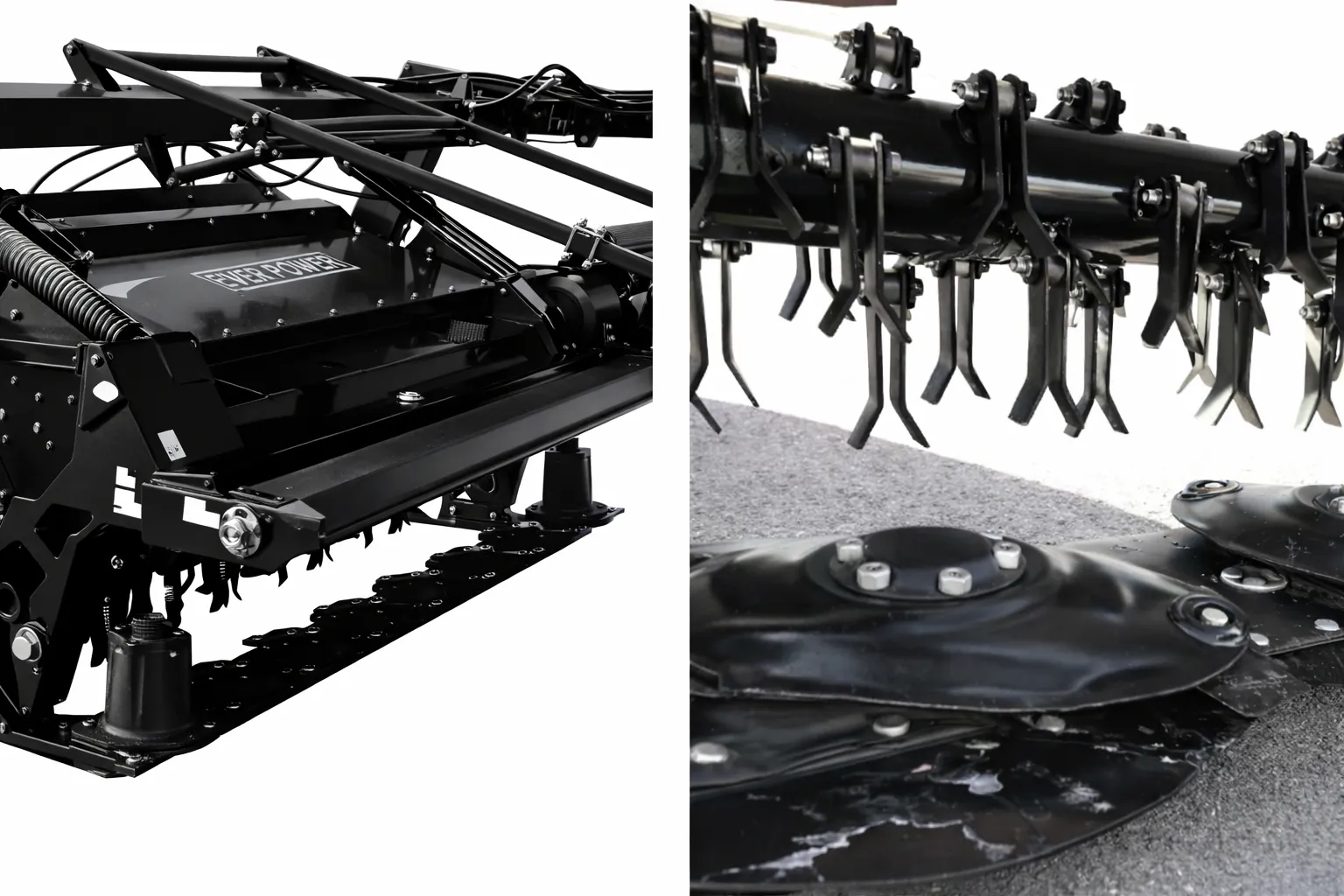

- High-Efficiency Cutting: Equipped with 8 rotary discs and 16 aerodynamic blades for a clean 3.2m cut at speeds up to 15 km/h.

- Advanced Conditioning: Features a flail/hammer-type conditioner that breaks stem cuticles to speed up moisture evaporation, crucial for humid climates.

- Terrain Adaptability: The independent dual-suspension system ensures the cutter bar follows ground contours precisely, protecting the turf.

- Safety Mechanism: Hydraulic obstacle avoidance system automatically resets the cutter bar after clearing obstructions.

- Robust Build: Weighing 2185kg, the heavy-duty chassis reduces vibration and ensures stability during high-speed operation.

3. Revolutionizing Forage Harvest: The 9GQY-3.2 Mower Conditioner

4. Engineering Excellence: Working Principles and Metallurgy

5. Regulatory Compliance: Machinery Safety and Land Management

Operating large-scale agricultural machinery like the 9GQY-3.2 requires strict adherence to safety and environmental regulations.

For our partners in South Korea, this machine is designed to comply with the Agricultural Mechanization Promotion Act. Specifically, the side-pull design includes a hydraulic swing mechanism that allows the unit to align directly behind the tractor for road transport, reducing the width to meet the requirements of the Korean Road Traffic Act for agricultural machinery. The machine is equipped with standard safety reflective markings and mounting points for slow-moving vehicle (SMV) signage. The PTO shaft is fully shielded with a CE-compliant guard to prevent entanglement, meeting ISO 4254-1 (Agricultural machinery safety) standards. This commitment to safety is crucial for protecting operators and minimizing liability for farm owners.

From a land management perspective, the 9GQY-3.2 supports sustainable farming practices. Soil compaction is a major concern globally and is strictly monitored under “Good Agricultural Practices” (GAP) guidelines in many nations. The 9GQY-3.2 addresses this by utilizing wide flotation tires (typically 400/60-15.5 or similar specs) that distribute the machine’s 2-ton weight over a larger surface area, minimizing ground pressure. Furthermore, the “Super Floating Protection” system ensures that the cutter bar glides over the soil rather than gouging it. This prevents damage to the grass root structure (sod), promoting faster regrowth for the next cut. In regions with strict soil conservation laws, such as the EU or protected wetlands in Asia, this ability to harvest reeds or forage without disturbing the soil profile makes the 9GQY-3.2 an environmentally responsible choice for land managers and contractors.

6. Market Trends: The Shift Towards Integrated Conditioning

The global forage harvesting market is undergoing a significant transformation, shifting from simple mowing operations to integrated mowing and conditioning processes. In South Korea, due to unstable haymaking conditions caused by the rainy season, demand for hay conditioners and mower-conditioners has increased by approximately 25% year-on-year. Farmers are realizing that the time saved by conditioning (often shortening drying time by a full day) determines the value of the final product: whether it’s high-value, high-quality silage or moldy, low-value feed.

Furthermore, the market is also showing a trend towards increased working widths. While 2.4-meter machines were once the standard, wider models like the 9GQY-3.2, with widths exceeding 3 meters, are becoming the new mainstream to match the increasing horsepower of modern tractors used in Korean cooperatives. The market is also showing a preference for flail-type conditioners over roller-type conditioners for forage crops, as flail-type conditioners are more effective at removing the waxy coating from the surface of the forage.

7. Tractor & Implement Compatibility

| घटक श्रेणी | संगतता विवरण |

|---|---|

| Tractor HP Range | Requires ≥110 HP (80.88 kW). Compatible with LS Mtron (XP/MT7 Series), TYM (T130), John Deere 6M Series, Kubota M6. |

| हाइड्रोलिक प्रणाली | Requires 2 sets of Rear Remote Valves (Double Acting) for lift control and swing tongue operation. |

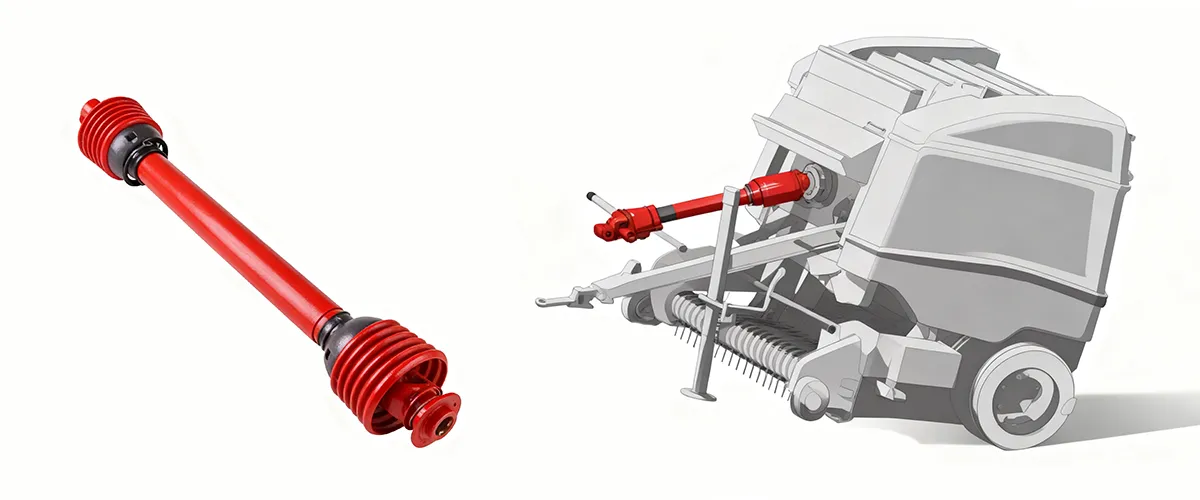

| पीटीओ कनेक्शन | Standard 1-3/8″ 6-Spline or 21-Spline shaft. 540/1000 RPM convertible input. |

| हिच टाइप | Drawbar / Pin Hitch. Suitable for Category II and III drawbars. |

| Blade Replacement | Uses standard quick-change or bolt-on twisted knives compatible with major “hay mower conditioner” aftermarket parts. |

*अस्वीकरण: ऊपर उल्लिखित अन्य ब्रांड नाम केवल उदाहरण के लिए दिए गए हैं। हम इन ब्रांड नामों वाले मूल उत्पाद या उपकरण प्रदान नहीं करते हैं।

8. Customer Success Story:

9. 9YG-1.25A राउंड बेलर की बिक्री के बाद की गारंटी और सहायता प्रणाली।

1. स्पेयर पार्ट्स की मरम्मत और प्रतिस्थापन।

2. प्रत्येक उत्पाद के साथ एक निःशुल्क उपयोगकर्ता मैनुअल आता है।

3. बिक्री के बाद सेवा और वारंटी/रखरखाव।

4. उत्पाद विश्व स्तर पर वितरित किये गए।

5. पेशेवर भाषा टीमें आपकी आवश्यकताओं को समझने के लिए संवाद करती हैं।

6. उत्पाद प्रशिक्षण.

7. हर साल घास काटने के मौसम के दौरान, हम उन सभी चरवाहों के लिए अनुवर्ती कार्रवाई और बाजार सर्वेक्षण करते हैं जिन्होंने हमारे उत्पादों को खरीदा और उपयोग किया है, और पहली बार उपयोगकर्ताओं के लिए तकनीकी प्रशिक्षण प्रदान करते हैं।

10. The 9YG-1.25A Round Baler after-sales guarantee and support system.

हमने अपने आधुनिक उत्पादन केंद्रों को अत्याधुनिक उपकरणों से सुसज्जित किया है, जैसे:

·ISO9001 गुणवत्ता प्रबंधन प्रणाली प्रमाणन

·सीएनसी लेजर कटिंग मशीनें

·लेजर और प्लाज्मा कटिंग सिस्टम

·स्वचालित असेंबली लाइनें

·इलेक्ट्रोस्टैटिक छिड़काव उत्पादन लाइनें प्रणालियाँ

·डिजिटल फैक्ट्री और औद्योगिक सॉफ्टवेयर

·डायनेमोमीटर परीक्षण स्टेशन इत्यादि

हमारे बारे में

11. Related components.

For those searching for “Shaft Collar for round balers” or “replacement Shaft Collar for hay baler,” our solution provides the precision and reliability needed for sustainable farming.

हम स्पेयर पार्ट्स भी उपलब्ध कराते हैं, जिनमें शामिल हैं: पीटीओ शाफ्ट और ट्रैक्टर गियरबॉक्स, ड्राइव चेन और स्प्रोकेट, शीव और पुली, पिकअप शाफ्ट बेयरिंग और शाफ्ट कॉलर, हे पिकर शाफ्ट और हे पिकर स्टैंड, स्किड्स और एब्रेशन प्लेट्स, टीथ और हे पिकर स्प्रिंग्स।

हमसे संपर्क करें, और हम आपको एक विस्तृत जानकारी भेजेंगे। पीडीएफ उपलब्ध प्रतिस्थापन पुर्जों में से।

12. Frequently Asked Questions (FAQ)

Q1. What is the price of the 9GQY-3.2 mower conditioner for sale delivered to Busan port?

A1. The price depends on steel costs and shipping logistics. For a precise CIF Busan quote including customs documentation, please contact our sales team directly via the “Get a Quote” button.

Q2. How does the 9GQY-3.2 compare to a john deere 630 moco in terms of cutting capacity?

A2. The 9GQY-3.2 offers a similar 3.2m (approx. 10ft 6in) cutting width and utilizes a comparable rotary disc system. While the JD 630 is a legendary machine, our model offers similar throughput and conditioning performance at a significantly more accessible price point.

Q3. Can I use this discbine for sale on a tractor with only 90 HP?

A3. We strictly recommend a minimum of 110 HP (80.88 kW). While a 90 HP tractor might lift it, it will struggle to maintain the PTO speed required for the conditioner and cutter bar in heavy crops, leading to clogging.

Q4. Is this machine suitable for harvesting tall reeds or bio-energy crops?

A4. Yes, the 9GQY-3.2 is specifically designed for gramineous forage and reeds. The rotary disc action cuts through thick, fibrous stems easily, and the conditioner helps break them down for processing.

Q5. What maintenance is required for the hay conditioner part of the machine?

A5. Regular maintenance includes checking the flail teeth for wear or damage, greasing the rotor bearings every 10 hours of operation, and checking the drive belt tension. It is a low-maintenance design.

Q6. Do you supply spare parts like blades compatible with new holland disc mower models?

A6. We supply a full range of OEM spare parts for the 9GQY series. Our blades use standard mounting dimensions, often making them interchangeable with generic aftermarket parts for major brands.

Q7. How does the “Super Floating Protection Device” work on rocky terrain?

A7. The system uses a hydraulic accumulator. When the cutter bar hits a rock, the resistance pressure triggers the hydraulics to instantly lift the bar up and over the obstacle, then lowers it back down, preventing damage to the discs.

Q8. Can I adjust the swath width for different baler pickups?

A8. Yes, the rear swath boards are adjustable. You can set the windrow width between 0.8 meters and 2.2 meters to match the pickup width of your round baler or square baler.

Q9. Are you a baler manufacturer or just a mower supplier?

A9. EVER-POWER is a comprehensive agricultural machinery manufacturer. We produce mowers, rakes, and balers. We can provide a full “farm-baler for sale” package deal including mower, rake, and baler for a complete harvest solution.

Q10. What is the Minimum Order Quantity (MOQ) for an OEM order with custom colors?

A10. For standard units, we can ship single sets. For full OEM customization (e.g., painting it green to match your John Deere fleet), we typically require a minimum order of 3 units.

संपादक: पीएक्सवाई