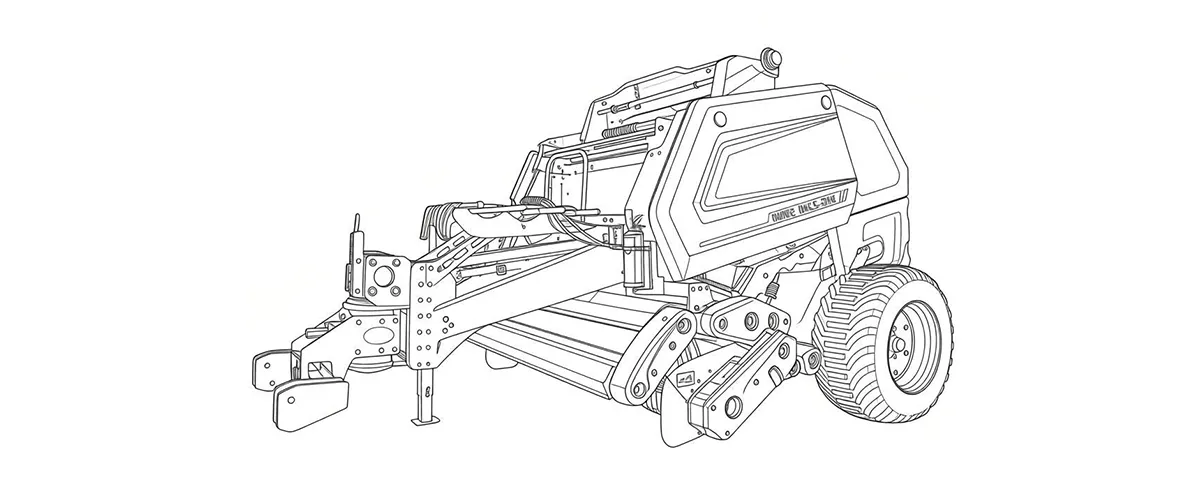

EP-9YG-2.24D-Mesin pengepres jerami bundar-Transcend

The 9YG-2.24D-Round baler-Transcend, designed by a professional farm baler manufacturer, is a traction-type agricultural machine tailored for hay, straw, and crop residue processing. It excels in gathering and compacting straw from corn, rice, wheat, and soybean fields into uniform round bales, directly addressing the pain points of scattered crop waste, high manual handling costs, and difficult storage in farming operations.

With a 2240mm pickup width, it efficiently collects crop residues in one pass, reducing the number of field operations and saving time for farmers. The 18-roller compression system ensures bale density ranges from 100-200 Kg/m³—dense enough to prevent loose bales during transportation while remaining easy to load/unload. Equipped with a sensor-controlled baling density system and net-wrapping function, it produces consistent, neatly wrapped bales that resist moisture, extending the storage life of forage or straw and reducing waste.

1. Product Highlights of the 9YG-2.24D-Round baler-Transcend.

Quick Hitching:

The cross drawbar can flexibly rotate vertically, allowing the tractor’s suspension arm mounting holes to be easily and securely connected via a pin for fast hitching.

Agile Turning:

The dual-gear gearbox can rotate up to 90 degrees left or right, significantly enhancing maneuverability during field turns and headland operations. Power transmission does not need to be disengaged during turning, reducing operator fatigue and improving transmission efficiency through gear-driven power transfer.

Robust & Durable:

The dual-gear gearbox is rigidly integrated with the drawbar, ensuring structural integrity on uneven terrain and preventing torsional damage to the drawbar or driveline. The machine features a self-developed double-cardan driveline with an added safety-torque shaft, which protects key components and eliminates driveline binding issues commonly encountered during tight turns in small fields.

High-Efficiency Hydraulic System:

The hydraulic system employs high-pressure H-type bite-type fittings, enabling rapid bale chamber opening and closing. A cushioning hydraulic cylinder is installed at the rear chamber to minimize mechanical shock and vibration during chamber closure. The heavy-duty gearbox delivers increased torque, while dual-side sprocket drives at the rear chamber ensure smoother and more efficient baling performance.

2. Technical Specifications of 9YG-2.24D-Round baler-Transcend.

| TIDAK. | Barang | Satuan | Spesifikasi |

|---|---|---|---|

| 1 | Nama Model | / | 9YG-2.24D Round Baler (S9000 Transcend) |

| 2 | Metode Pengait | / | Jenis Traksi |

| 3 | Lebar Pickup | mm | 2240 |

| 4 | Jenis Struktur Pickup | / | Jenis Gigi Pegas |

| 5 | Jenis Struktur Pengumpan | / | Tooth Bar + Drum Type |

| 6 | Compression Chamber Baler Structure Type | / | Jenis Drum |

| 7 | Lebar Ruang Kompresi | mm | 1400 |

| 8 | Diameter Ruang Kompresi | mm | Φ1200 |

| 9 | Number of Rolling Compression Components | buah | 18 (Drum) |

| 10 | Rolling Compression Drum Diameter | mm | Φ222 |

| 11 | Baling Method | / | Pembungkus Jaring |

| 12 | Matching Power | kW | 55-100 |

| 13 | Berat Struktural | kg | 4570 |

| 14 | PTO (Power Take-Off) Shaft Speed | putaran/menit | 720 |

| 15 | Overall Dimensions (Length × Width × Height) | mm | 4600×3010×2370 (in working condition) |

| 16 | Kontrol Kepadatan Bale | / | Kontrol Sensor |

| 17 | Ukuran Bal (Diameter × Lebar) | mm | Φ1300×1400 |

| 18 | Kepadatan Bale | Kg/m³ | 100-200 |

| 19 | Produktivitas | bales/h | 40~100 |

| 20 | Jejak Roda | mm | 2600 |

| 21 | Kecepatan Operasional | Km/jam | 5-35 |

| 22 | Net Wrap Specification (Length × Width) | / | 2000×1.4m/roll |

3. Directly Addressing Market Demand:

- Meningkatnya Permintaan Didorong oleh Peternakan

Ekspansi peternakan sapi perah dan sapi potong yang stabil di Korea menciptakan permintaan yang konsisten akan pakan ternak berkualitas tinggi, termasuk silase dan jerami kering. Mesin Baler Bulat Transcend 9YG-2.24D sangat cocok untuk digunakan di peternakan dan fasilitas pengolahan pakan. - Kompatibilitas Tanaman yang Luas

Mesin pembuat bal kami secara efisien menangani berbagai jenis tanaman, termasuk:

gandum, jerami padi, alang-alang, batang kapas, alfalfa, rumput padang rumput, silase jagung, residu tebu, dan masih banyak lagi. - Populasi Pedesaan yang Menua Membutuhkan Peralatan Hemat Tenaga Kerja

With over 40% of Korean farmers aged 65 or older, the government actively subsidizes “labor-saving” and “smart” agricultural machinery. Our 9YG-2.24D Transcend Round Baler directly addresses this need—featuring “no power interruption required during turns” and “reduced operator fatigue”—making it perfectly aligned with current market demands. - Layanan Purnajual Proaktif

Selama setiap musim panen jerami tahunan, kami melakukan kunjungan lanjutan dan survei pasar kepada setiap pelanggan. Pengguna baru akan menerima pelatihan teknis langsung, dan semua mesin dilengkapi dengan garansi dan dukungan perbaikan yang komprehensif. - Solusi yang Disesuaikan

Kami menawarkan konfigurasi mesin yang berbeda yang disesuaikan dengan peraturan transportasi setempat dan kondisi lapangan di wilayah Anda. - Dukungan Suku Cadang & Perawatan

Kami menyediakan layanan penggantian suku cadang lengkap. Jika ada komponen mesin pengepres Anda yang aus dan perlu diganti, silakan hubungi kami. Daftar lengkap suku cadang yang tersedia tersedia di bawah ini.

4. Why does the Korean market need the 9YG-2.24D-Round baler-Transcend?

Korean agriculture faces unique challenges: most farms are small-scale with fragmented fields (due to mountainous terrain), an aging agricultural workforce causes labor shortages, frequent rainy seasons increase the risk of crop mildew, and the livestock industry requires high-quality silage. The 9YG-2.24D-Round baler-Transcend directly addresses these issues, making it an essential tool for Korean farmers.

For Korea’s fragmented small fields, this traction-type round baler is equipped with a dual-link gearbox that rotates 90 degrees left and right, allowing flexible turns in narrow plots without frequent machine adjustments—saving time compared to larger balers that struggle on small-scale terrain. Its 2240mm pickup width covers moderate areas in a single pass, reducing the number of field trips and easing the workload for elderly farmers. Designed with Korea’s rainy climate in mind, the machine's net-wrapping function tightly seals the bales.

5. Why choose us?

For farmers and livestock breeders who face heavy straw handling tasks Dan labor shortages, the 9YG-2.24D-Transcend Round Baler from our farm baler manufacturer is a down-to-earth and reliable solution. As a professional farm baler supplier, we match the actual agricultural scenarios in South Korea—whether it’s processing rice, barley, or corn straw in fragmented fields, or handling forage for livestock farms, this farm baler delivers consistent performance.

It's 2240mm pickup width covers a large area in one pass, reducing the number of trips across the field and saving time for farmers with limited labor. The spring-tooth pickup structure gently grabs straw without damaging the material, while the drum-type compression chamber forms tight, uniform round bales. Equipped with sensor-controlled density adjustment, you can get bales with 100-200 Kg/m³ density as needed—dense enough for easy stacking and transportation, yet not too hard to unpack for feeding.

5. Customer Reviews and Case Studies of 9YG-2.24D-Transcend Round Baler.

Client1 Profile: Mongolia

Ulasan Pelanggan:

"Our pasture mainly stores sheep grass and alfalfa. In the past, we relied on manual baling—five people could only handle over 20 bales a day, and we were so tired that we could barely straighten our waists. After purchasing the 9YG-2.24D, I can handle a huge number of bales alone by towing it with a tractor. The 2240mm width is particularly suitable for open grasslands, and the spring-tooth pickup does not pull up the grass roots, thus protecting the pasture. The bale density is stated to be between 100-200 Kg/m³! They don’t take up much space when stacked in the shed, and it’s convenient to unpack them for feeding cattle and sheep in winter. Most importantly, the temperature difference between morning and evening here is large, but the machine’s gearbox and drive shaft have never had any failures. It is more durable than the previous European brand we used, and the maintenance cost is much lower."

Profil Klien2: Kazakhstan

Ulasan Pelanggan:

"We grow a lot of wheat here, and straw disposal after harvest used to be a big headache. In the past, we either burned it (which pollutes the environment) or hired people to haul it away—both options were costly. The 9YG-2.24D has solved this trouble for us. It directly turns straw into round bales in the field, and the net wrapping is tight enough. As long as the straw is dry enough, it won’t get moldy even after six months of storage. The old tractor on our farm can drive it perfectly. Its productivity is about 60 bales per hour, and we finished handling the straw from 10 hectares of wheat in just two days. Now we can even sell these straw bales to the nearby cattle farm as feed—we’ve got an extra income stream, haha."

6. Skenario Aplikasi Baler Bulat 9YG-2.24D-Transcend.

I. Skenario Pemanenan dan Penyimpanan Pakan Ternak di Padang Rumput dan Padang Penggembalaan

Kepadatan bal dapat disesuaikan antara 100-200 kg/m³, sehingga menghemat ruang gudang saat ditumpuk dan disimpan. Membongkar bal memudahkan untuk memberi makan sapi dan domba di musim dingin. Cocok untuk kebutuhan panen dan penyimpanan hijauan harian di padang rumput keluarga dan padang rumput skala menengah hingga besar, satu orang dapat mengoperasikannya untuk menggantikan banyak pekerja, sehingga sangat mengurangi intensitas tenaga kerja.

II. Skenario Pemanfaatan Sumber Daya Jerami Tanaman

Produk ini mengatasi masalah polusi akibat pembakaran jerami dan tingginya biaya tenaga kerja untuk transportasi. Produk ini dapat langsung mengubah jerami menjadi bal-bal bundar yang padat di ladang. Pembungkus jaringnya dapat menahan erosi angin, pasir, dan hujan, dan jerami tidak mudah berjamur setelah 6 bulan penyimpanan. Jerami yang telah diolah dapat diolah menjadi pakan ternak, bahan baku bahan bakar biomassa, dll.

III. Skenario Penyiapan Pakan Silase di Peternakan

Produktivitas tinggi sebesar 100 bal per jam dapat memenuhi kebutuhan pemanenan dan penyimpanan silase di peternakan selama musim puncak, dan cocok untuk pekerjaan persiapan pakan skala besar di peternakan sapi perah besar dan peternakan sapi potong.

IV. Skenario Operasional di Lingkungan dan Plot Khusus

1. Low-temperature Operation Scenarios: Cold regions such as Krasnoyarsk Krai, Russia. The transmission system can adapt to the low-temperature environment, start and operate stably, and ensure straw/forage harvesting and storage in winter.

2. Scattered Small Plot Scenarios: Areas with scattered plots, such as Dornod Province, Mongolia. The traction-type design has flexible steering and can operate in small plots without frequent adjustments.

6. Sistem jaminan dan dukungan purna jual untuk mesin pembuat bal jerami pertanian 9YG-2.24D-Round Baler-Transcend.

1. Perbaikan dan penggantian suku cadang.

2. Setiap produk dilengkapi dengan panduan pengguna gratis.

3. Layanan purna jual dan garansi/perawatan.

4. Produk dikirim secara global.

5. Tim bahasa profesional berkomunikasi untuk memahami kebutuhan Anda.

6. Pelatihan produk.

7. Setiap tahun selama musim pemotongan rumput, kami melakukan tindak lanjut dan survei pasar untuk setiap penggembala yang telah membeli dan menggunakan produk kami, dan memberikan pelatihan teknis bagi pengguna pertama kali.

7. Tentang kami

Kami telah melengkapi basis produksi modern kami dengan peralatan mutakhir, seperti:

·Mesin pemotong laser CNC

·Sistem Pemotongan Laser & Plasma

·Jalur Perakitan Otomatis

·Sistem jalur produksi penyemprotan elektrostatik

·Pabrik Digital & Perangkat Lunak Industri

·Stasiun Pengujian Dinamometer dan sebagainya

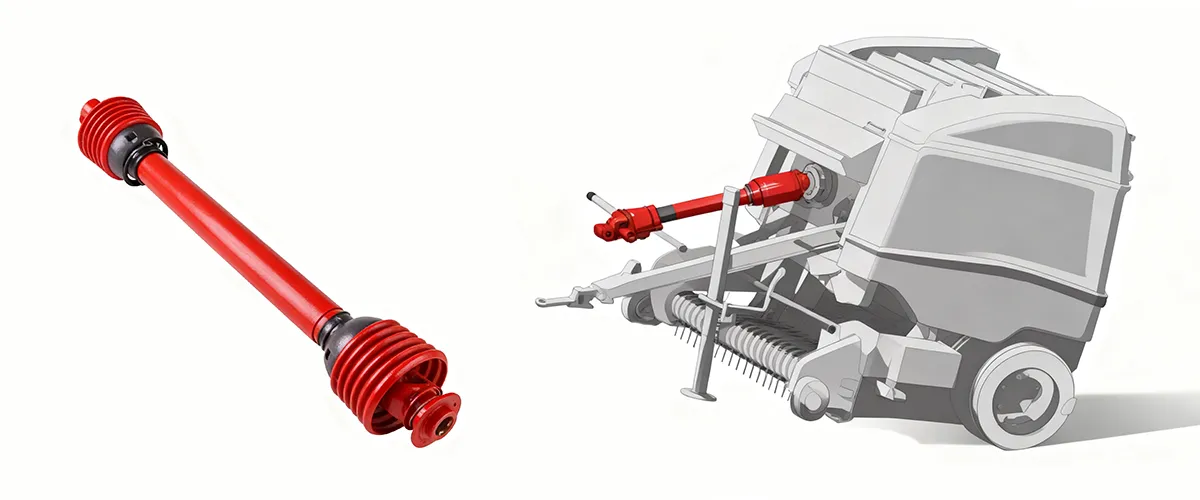

8. Komponen terkait.

Related components: agricultural-pto-shaft

PTO shafts are used to provide power to various machinery. By transferring the engine's rotational energy to the working tools, PTO shafts are the most common solution. PTO shafts are often used to tow heavy machinery.

However, if used improperly or neglected over time, they may fail and cause damage to the equipment. If you are troubled by a damaged PTO drive shaft, feel free to Hubungi kami, and we will provide you with suitable replacement parts for your PTO drive shaft.

9. Tanya Jawab

Q1:What types of crops can this baler handle?

A1: It mainly handles high-quality forages such as sheep grass and alfalfa, as well as straw from harvested crops, including wheat, rice straw, reed, cotton stalks, alfalfa, pasture grass, corn silage, sugarcane residue, and more. It is suitable for various scenarios like grassland pastures and planting fields, realizing "one machine for multiple uses".

Q2:Are the bale density and size fixed, or can they be adjusted?

A2: The bale density is flexibly adjustable between 100-200 Kg/m³, which can be adapted according to storage needs or crop types. Featuring high regularity for easy stacking and transportation.

Q3:What is the actual productivity of this baler during operation?

A3: The productivity under normal working conditions is 40-100 bales per hour, which is specifically affected by crop density and plot flatness. For example, it can handle wheat straw at a rate of 50 bales per hour, and the productivity can be increased to 100 bales per hour during the peak season of silage preparation, ensuring efficient completion of harvesting and storage tasks.

Q4:Can the machine adapt to low-temperature environments when used in cold regions like Russia?

A4:Absolutely. Its transmission system is designed for low-temperature adaptation, and it can start and operate stably even in a low-temperature environment, ensuring normal straw or forage harvesting and storage operations in winter.

Q5:Is there any guarantee for after-sales service and spare parts supply if the machine breaks down after purchase?

A5:There is a comprehensive guarantee. We have a dedicated spare parts warehouse to ensure the timely supply of parts. Our professional after-sales team provides technical support to resolve equipment malfunctions, preventing any impact on production schedules.

Editor PXY