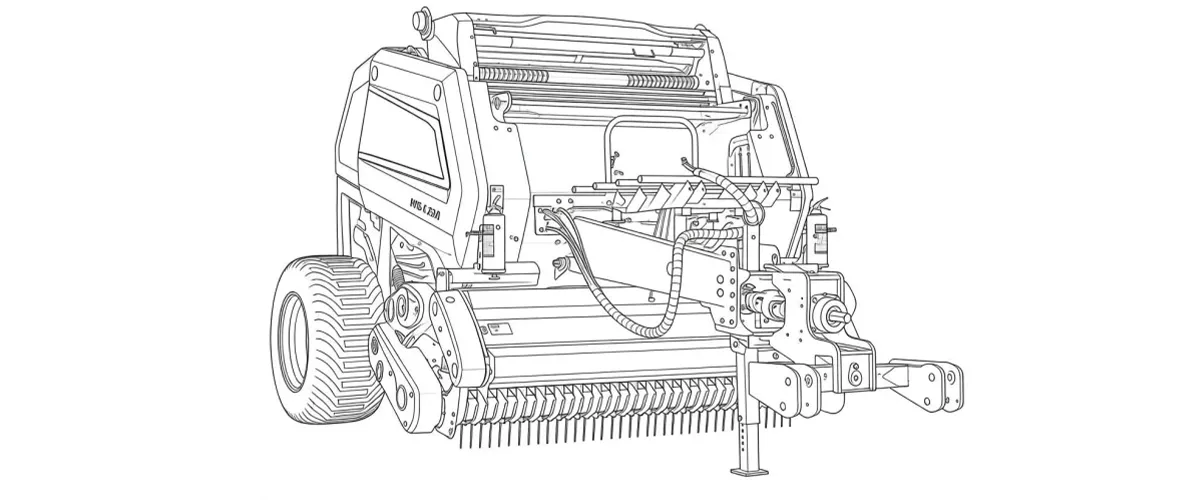

Pressa rotonda EP-9YG-1.25A

The 9YG-1.25A Round Baler is a towed round baler designed specifically for farms seeking higher baling efficiency and bale density. Equipped with 18 steel rollers and an automatic winding system, the 9YG-1.25A Round Baler exhibits exceptional stability when handling damp hay or coarse corn stalks, preventing slippage and clogging, and providing users with tight, regularly shaped bales, optimizing transportation and storage efficiency.

1. Key selling points of the 9YG-1.25A Round Baler.

Large Capacity and High Efficiency: This model can produce large-diameter round bales of Φ1300×1250 mm, with a larger single bale volume compared to ordinary models, and boasts a high productivity of 40-100 bales/hour, significantly improving field operation efficiency.

Heavy-Duty Construction and Durability: With a total structural weight of 4472 kg, the robust heavy-duty chassis design ensures the machine's stability and service life under harsh working conditions.

High-Density Compaction Technology: The compression chamber is equipped with 18 steel rollers and uses an automatic netting system, combined with sensor control, to compress bale density to 100-200 kg/m³.

2. Why the 9YG-1.25A Round Baler is Your Efficient Harvesting Solution?

18-Roller Chamber for Higher Density

The compression chamber consists of 18 thickened steel rollers, each 222mm in diameter, with a non-belt structure. Unlike belts, the roller structure does not stretch or slip under heavy loads. It applies continuous pressure, achieving a bulk density of 100-200 kg/m³. For silage, this means more thorough air removal; for hay, it means greater transport weight per vehicle, saving on freight costs.

Larger 1.3m Round Balers

This equipment produces bales with dimensions of Φ1300 × 1250 mm. Compared to the standard 1.2-meter model, the 1.3-meter diameter means an approximately 15%-20% increase in bale volume. In the same operating time, it reduces the number of stops for unloading and netting, significantly improving overall field productivity (40-100 bales/hour).

Robust Feeding & Pickup System

2150mm pickup width, combined with a toothed roller + drum type forced feeding.2150mm pickup width can be a replacement of John Deere. The 2.15-meter width is sufficient to cover the straw of most combine harvesters. Even with thick corn stalks, it can smoothly handle them, reducing clogging downtime.

3. Technical Specifications of 9YG-1.25A Round baler.

| NO. | Articolo | Unità | Specifica |

|---|---|---|---|

| 1 | Nome del modello | / | Pressa rotonda 9YG-1.25A |

| 2 | Tipo di attacco | / | Traction |

| 3 | Larghezza di ripresa | mm | 2150 |

| 4 | Tipo di struttura di ritiro | / | Tipo di dente a molla |

| 5 | Feeding Structure Type | / | Tine Roller + Roller Type |

| 6 | Compression Chamber Mechanism Type | / | Roller Type |

| 7 | Larghezza della camera di compressione | mm | 1250 |

| 8 | Diametro della camera di compressione | mm | Φ1200 |

| 9 | Number of Compressing Components | pc | 18 (Rollers) |

| 10 | Compression Roller Diameter | mm | Φ222 |

| 11 | Binding Method | / | Net Wrap |

| 12 | Potenza abbinata | kW | ≥75 |

| 13 | Peso strutturale | kg | 4472 |

| 14 | Velocità della presa di forza | giri/min | 540-1000 |

| 15 | Overall Dimensions (L×W×H) | mm | 4400×2850×2400 (Working State) |

| 16 | Controllo della densità delle balle | / | Controllo del sensore |

| 17 | Dimensioni della balla (diametro × larghezza) | mm | Φ1300×1250 |

| 18 | Densità della balla | kg/m³ | 100-200 |

| 19 | Produttività | Bales/h | 40~100 |

| 20 | Traccia della ruota | mm | 2450 |

| 21 | Velocità operativa | chilometri all'ora | 5-35 |

| 22 | Net Wrap Specification (L×W) | / | 2000X1.25 m / Roll |

4. 9YG-1.25A Round Baler directly addresses market demand.

Application Scenarios in India

India – Sugarcane Trash Management in Maharashtra

Scenario: Collection of sugarcane leaves around sugar mills for use in boiler co-firing.

Local Challenges: Sugarcane fields have tall ratoons, making the ground extremely bumpy. Lightweight balers would practically fall apart in such conditions.

The 9YG-1.25A's Approach:

Heavy Duty Chassis: With a structural weight of 4472kg, it far exceeds that of ordinary models. This "tank-like" weight maintains extremely high stability on uneven terrain and is exceptionally durable, meeting the contractor's primary requirement of "robustness."

Application Scenarios in Trans-India Border Application

Trans-India Border Application – Commercial Fodder Bank Construction

Scenario: Large-scale baling of wheat straw (Turi/Bhusa) during the bumper harvest season for storage and sale at higher prices during the dry season.

Pain Point: Long storage period of 6-8 months requires extremely high precision in maintaining the shape of the bales.

9YG-1.25A's Approach:

Net Wrap: The automatic net wrapping system ensures a smooth and compact bale surface, preventing collapse during stacking and offering better protection against the risk of loosening during long-term storage compared to hemp rope.

5. Customer Reviews and Case Studies of 9YG-1.25A Round Baler.

Client1 Profile: India

Recensioni dei clienti:

"The paddy fields are uneven, and the straw is full of dust. We switched to the 9YG-1.25A because of its heavy structure. Unlike lighter balers that crack under stress, this tank keeps running. The 18 steel rollers grip the straw perfectly. We are supplying denser bales to the biomass plant."

Client2 Profile: India

Recensioni dei clienti:

"Harvesting sugarcane trash is a bumpy ride because of the root stubble. We needed a baler that wouldn't fall apart. The 9YG-1.25A's reinforced chassis absorbs the shocks amazingly well. It requires a big tractor (>75kw/HP), but the speed and bale density we get are worth every rupee."

6. Application Scenarios of the 9YG-1.25A Round Baler.

1. Mexico – Dry Season Feed Storage and Commercialized Forage

Scenario 1: Heavy-duty recycling of corn stalks (Rastrojo), for example, in Jalisco

Mexico has a long dry season, and beef cattle farming relies on corn stalks. Local corn stalks are tall and robust, making ordinary balers prone to chassis breakage.

Scenario 2: Commercialized export baling of alfalfa from the north

For example, high-quality alfalfa is grown in the north (such as Chihuahua) for export or long-distance transport to the southern dairy belt. Combined with automatic wrapping, alfalfa leaves are preserved to the maximum extent, producing high-density, high-protein hay bales that meet commercial trading standards.

2. Kazakhstan – Vast Steppes and Long-Distance Logistics

Scenario 3: High-density logistics optimization of wheat straw, for example, in the northern grain-producing region

Trucks can easily transport hundreds of kilometers; "heavier and denser bales" directly translate to lower transportation costs per ton.

Scenario 4: Grassland harvesting operations in response to variable weather

Grassland weather is unpredictable, with blizzards arriving early. 3. South Korea – Silage Operations by Professional Service Teams

Scenario 5: High-Moisture Silage Production, e.g., from Southern Ryegrass (IRG)

Southern Korea widely cultivates ryegrass for silage bale production. The high moisture content of the raw material makes the conveyor belts prone to slipping. An all-steel roller compression chamber is ideal for handling wet grass. The ribs on the rollers forcefully grip the slippery ryegrass for rotational compression, ensuring the continuity and compactness of the silage baling process, meeting the high standards of cattle for fermented feed.

4. Brazil – Biomass Energy and Intensive Agriculture

Scenario 6: Energy Recovery from Sugarcane Leaves in São Paulo (Biomass)

Sugar mills urgently need to recover thick layers of sugarcane leaves from the fields for power generation, but the sugarcane fields have high rootstocks and extremely bumpy ground. The machine's 4.5-ton weight gives it strong shock resistance, allowing it to move stably in harsh sugarcane fields.

5. Cross-border Application Scenario – Standardized Production in Large Livestock Enterprises

Scenario 7: Total Mixed Ration (TMR) Raw Material Preparation in Large Dairy/Beef Feedlots

Large ranches using TMR mixers require bales of uniform size and density. The 1.3-meter standard round bales produced by the 9YG-1.25A are regular in shape and uniform in density, making them very easy for TMR equipment to grasp and crush. The netting system ensures that no hemp rope fragments get mixed into the feed during unpacking, protecting the health of livestock.

7. The 9YG-1.25A Round Baler after-sales guarantee and support system.

1. Riparazione e sostituzione di pezzi di ricambio.

2. Ogni prodotto è corredato da un manuale utente gratuito.

3. Assistenza post-vendita e garanzia/manutenzione.

4. Prodotti consegnati in tutto il mondo.

5. I team linguistici professionisti comunicano per comprendere le tue esigenze.

6. Formazione sul prodotto.

7. Ogni anno, durante la stagione del taglio dell'erba, effettuiamo controlli e indagini di mercato per ogni pastore che ha acquistato e utilizzato i nostri prodotti e forniamo formazione tecnica a chi li utilizza per la prima volta.

8. Sistema di garanzia e assistenza post-vendita per la rotopressa 9YG-1.25A.

Abbiamo dotato le nostre moderne basi di produzione di attrezzature all'avanguardia, quali:

·Certificazione del sistema di gestione della qualità ISO9001

·Macchine per il taglio laser CNC

·Sistemi di taglio laser e plasma

·Linee di assemblaggio automatizzate

·Sistemi di linee di produzione per spruzzatura elettrostatica

·Software per fabbriche digitali e industriali

·Stazioni di prova dinamometriche e così via

Chi siamo

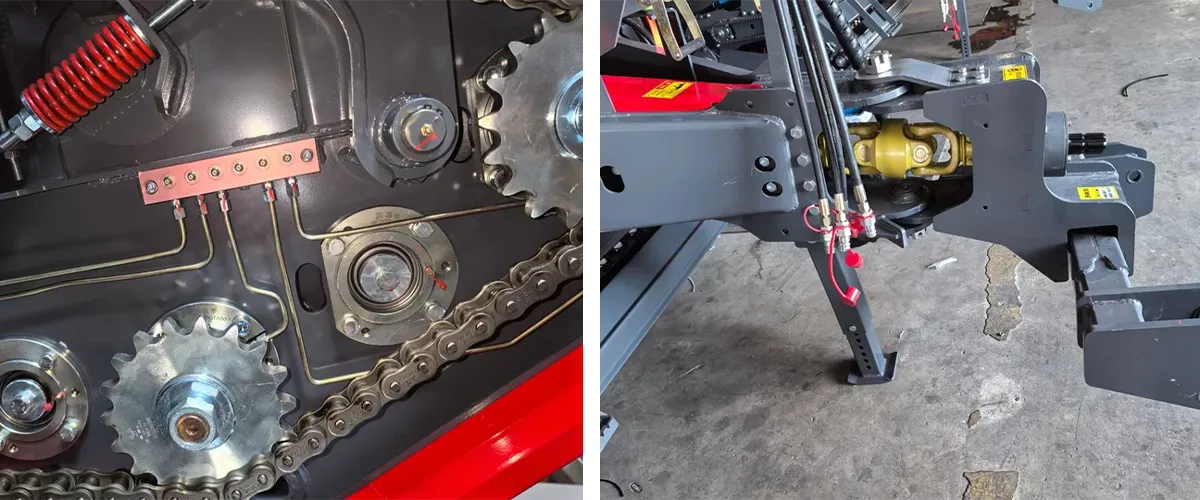

9. Componenti correlati.

For those searching for "Shaft Collar for round balers" or "replacement Shaft Collar for hay baler," our solution provides the precision and reliability needed for sustainable farming.

Offriamo anche pezzi di ricambio, tra cui Albero cardanico e cambio del trattore, catena di trasmissione e pignone, puleggia e puleggia, cuscinetti dell'albero di raccolta e collare dell'albero, albero e supporto per raccoglitore di fieno, slitte e piastre di abrasione, denti e molle per raccoglitore di fieno.

Contattaci, and we'll send you a detailed PDF di pezzi di ricambio disponibili.

Domande frequenti:

Q1.What other replacement parts do we provide?

A1: Our replacement parts include:

1. PTO shaft & agricultural gearbox assemblies

2. Chains & sprockets (heavy-duty roller chain drives)

3. Belts & pulleys/tensioning mechanism parts

4. Bearings, bearing housings, bushings & shaft locks

5. Wear parts for hay picking systems: spring teeth, hay picking shafts, slippers, wear plates, etc.

6. Knotting/wrapping system accessories: knotter gears, blades, friction plates, guide wheels, etc.

7. Baling chamber/compacting system accessories: rollers, roller sprockets, liners, pulleys, shafts, etc.

8. Hydraulic & control components: hydraulic cylinders, O-rings, hoses, control cables, and accessories.

Q2.What is the rotational speed of the power take-off shaft of the 9YG-1.25A round baler?

A2: The power output shaft speed of the 9YG-1.25A round baler is approximately 540-1000 r/min, falling within this range.

Q3.Is 9YG-1.25A a roller baler or a belt baler?

A3: It is a roller-type baler featuring 18 heavy-duty steel rollers in the compression chamber. Roller balers are superior for handling wet silage and heavy corn stalks because they provide positive grip and rotation, eliminating the belt slippage issues common in belt balers.

Q4.How heavy is the machine, and why does weight matter?

A4: This model has a structural weight of 4472 kg. This heavy-duty construction ensures durability and stability when operating on rough terrain or handling dense crops like corn stalks, reducing vibration and wear.

Q5.how to use the round baler?

A5:When using a round baler, first adjust the pickup height and prepare the machine. Then, drive the tractor along the crop, and the baler will feed the crop into the baling chamber, bundle it, and then discharge the bales from the rear.

Redattore: PXY