説明

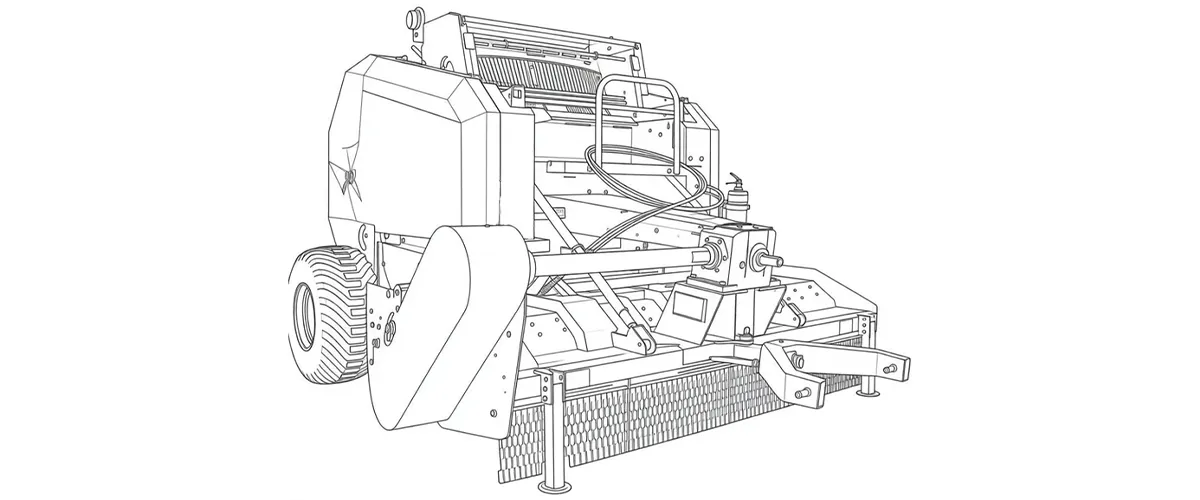

1. Technical Specifications: 9YG-1.0C Series

| いいえ。 | アイテム | ユニット | 仕様 |

|---|---|---|---|

| 1 | モデル名 | / | 9YG-1.0C Type Round Baler |

| 2 | ヒッチタイプ | / | Trailed |

| 3 | Pickup Width | んん | 2400 |

| 4 | Pickup Mechanism Type | / | Roller-type |

| 5 | Inlet Mechanism Type | / | Flail-type + Push and Pull System |

| 6 | Pickup Chamber Size | んん | 1250 |

| 7 | Pickup Chamber Diameter | んん | Φ1000 |

| 8 | Roller Workpiece Count | pieces | 16 (Flail-type) |

| 9 | Roller Pressure Diameter | んん | Φ222 |

| 10 | Pickup Type | / | Mesh-type |

| 11 | Required Power | Kw/hp | ≥69.8/95 |

| 12 | 機械重量 | kg | 3198 |

| 13 | Output Shaft Speed | 回転数 | 540 |

| 14 | External Dimensions (L × W × H) | んん | 3800 × 2850 × 2200 (Working Condition) |

| 15 | Grass Density Control | / | Sensor Control |

| 16 | Grass Size (Length × Width) | んん | Φ1000 × 1250 |

| 17 | Grass Density | kg/m³ | 115–200 |

| 18 | 生産性 | rake/h | 40–100 |

| 19 | Wheel Diameter | んん | 2100 |

| 20 | Operating Speed | Km/h | 5–20 |

| 21 | Pickup Width | メートル | 2000 × 1.25 m/Bale |

2. 9YG-1.0C Round Baler: The Ultimate Solution for High-Density Corn and Silage Baling

3. Engineering Excellence: Mechanics, Materials, and Application Scenarios

4. Global Regulatory Compliance: Safety, Emissions, and Land Management

5. Tractor & Component Compatibility

| System / Component | Compatibility Details |

|---|---|

| Tractor Brands (Korea/Global) | Compatible with LS Mtron (XP Series), TYM (T1003), Daedong/Kioti (HX Series), John Deere (6M Series). Requires 95HP+. |

| Hydraulic Output | Requires 2 sets of rear remote hydraulic valves (Double Acting) for pickup lift and tailgate operation. |

| Binding Material | Standard 1230mm or 1250mm Net Wrap. Compatible with Tama, Novatex, and generic “round baler brands” netting. |

| PTO接続 | Standard 1-3/8″ 6-Spline shaft. Includes wide-angle CV joint for tight turns (optional). |

*免責事項:上記のその他のブランド名は、あくまでも説明目的であり、当社はこれらのブランド名を冠したオリジナル製品や機器を提供するものではありません。

6. Market Trends: The Shift Towards High-Density Silage and Biomass

7. Customer Success Story:

Client1 Profile: South Korean Dairy Farmer

Customer Reviews:

“We’ve been using the 9YG-1.0C round baler for several months, and it’s been a game-changer for us. The hammer claw pickup system makes handling wet rice straw easy without the usual clogging issues. The bale density is excellent, and we can now produce silage that’s perfect for winter feeding. The machine is a real time-saver, and it significantly reduces our labor costs. Highly recommended for anyone needing a reliable, high-capacity baler.”

Client2 Profile: U.S. Agricultural Equipment Dealer

Customer Reviews:

“As a dealer in the U.S., we’ve sold several 9YG-1.0C round balers to our customers in the Midwest. The feedback has been overwhelmingly positive. Farmers appreciate its versatility – from dry hay to silage production. The durability and low maintenance costs have made it a top choice for those seeking reliable, cost-effective machinery. It works exceptionally well with both high-moisture crops and tough, fibrous residues like corn stalks.”

Client3 Profile: Australian Cattle Farmer

Customer Reviews:

“Using the 9YG-1.0C round baler has improved our silage production immensely. It handles our high-density corn stover effortlessly and produces consistently tight bales that are perfect for our cattle. The fuel efficiency is another standout feature – we’ve seen a noticeable reduction in fuel consumption compared to our previous baler. The baler’s design also helps reduce soil compaction, which is vital for our land’s long-term health.”

Client4 Profile: South Korean Rice Straw Processor

Customer Reviews:

“We operate in a region where rice straw needs to be processed quickly before the wet season sets in, and the 9YG-1.0C has been perfect for the job. Its semi-forced feeding system and automatic net binding feature allow us to handle large volumes of rice straw without any issues. The machine is easy to operate and maintain, and we’ve had excellent results with it. It’s definitely made our harvest season more efficient.”

Client5 Profile: European Agricultural Machinery Importer

Customer Reviews:

“We’ve been importing and selling the 9YG-1.0C round baler in Europe for over a year now, and the response has been fantastic. The machine is robust, yet compact enough to fit in regions with smaller land plots. Farmers in coastal areas, especially, appreciate the baler’s corrosion resistance. It’s ideal for both hay and silage, and its efficient fuel consumption and easy maintenance make it a great investment for farmers seeking sustainability and high productivity.”

8. 9YG-1.25Aラウンドベーラーのアフターセールス保証およびサポートシステム。

1. スペアパーツの修理および交換。

2. すべての製品には無料のユーザーマニュアルが付属しています。

3. アフターサービスと保証・メンテナンス。

4. 製品は世界中に配送されます。

5. プロフェッショナルな言語チームがコミュニケーションを取り、お客様のニーズを理解します。

6. 製品トレーニング。

7. 毎年、草刈りシーズンになると、当社製品を購入・使用したすべての牧畜民に対してフォローアップと市場調査を実施し、初めて使用する人には技術研修を行っています。

9. The 9YG-1.25A Round Baler after-sales guarantee and support system.

We’ve outfitted our modern production bases with cutting-edge equipment, such as:

·ISO9001品質マネジメントシステム認証

·CNC laser cutting machines

·Laser & Plasma Cutting Systems

·Automated Assembly Lines

·Electrostatic spraying production lines Systems

·Digital Factory & Industrial Software

·Dynamometer Testing Stations and so on

私たちについて

10. Related components.

For those searching for “replacement components hay baler,” our solution provides the precision and reliability needed for sustainable farming.

We also offer spare parts, including PTO Shaft & Tractor Gearbox, Drive Chain & Sprocket, Sheave & Pulley, Pickup Shaft Bearings & Shaft Collar, Hay Picker Shaft & Hay Picker Stand, Skids & Abrasion Plates, Teeth & Hay Picker Springs.

お問い合わせ、 詳細な資料をお送りします PDF 交換部品の入手可能性。

Frequently Asked Questions (FAQ)

Q1. What is the approximate cost of the 9YG-1.0C round baler including shipping to Busan, South Korea?

A1. The FOB price varies based on raw material costs and customization. For a precise CIF Busan quote that includes shipping and insurance, please contact our sales team directly via the “Get a Quote” button.

Q2. Can this heavy-duty baler handle wet corn stalks for silage without clogging the chamber?

A2. Absolutely. The 9YG-1.0C is specifically designed as a silage round baler. Its hammer claw pickup and semi-forced feeding system actively push wet material into the chamber, preventing the clogs common in standard hay balers.

Q3. Which tractor horsepower is strictly required to operate the 9YG-1.0C efficiently in hilly terrain?

A3. While the minimum requirement is 95 HP, for hilly terrain like in Gangwon-do, we recommend a tractor with at least 105-110 HP to ensure safe towing and consistent PTO power maintenance under load.

Q4. How does the 9YG-1.0C compare to a vermeer round baler in terms of maintenance costs and parts?

A4. The 9YG-1.0C offers comparable durability to premium brands like Vermeer but with significantly lower parts costs. We use standard chain sizes and bearings, making maintenance affordable and parts easy to source globally.

Q5. Is it possible to use this machine as a hay baler for sale near me for dry alfalfa harvesting?

A5. Yes, by swapping the hammer claw pickup for the standard tine pickup, this machine functions perfectly as a high-capacity dry hay baler, treating delicate alfalfa leaves gently while maintaining high density.

Q6. Where can I find a reliable baler manufacturer that offers OEM branding for my dealership?

A6. EVER-POWER is a premier baler manufacturer offering full OEM services. We can paint the machine in your brand colors (e.g., John Deere green or Kubota orange) and apply your decals for a seamless addition to your product line.

Q7. What type of net wrap does the 9YG-1.0C use, and is it available in the Korean market?

A7. It uses standard 1230mm or 1250mm wide net wrap. This size is a universal standard and is widely available from agricultural suppliers throughout South Korea and international markets.

Q8. How does the hammer claw pickup differ from a standard tine pickup on a small round baler?

A8. A standard tine pickup uses wire teeth to lift light hay. The hammer claw pickup uses robust, flail-like claws designed to shatter and lift heavy, rigid corn stalks directly from the ground, preventing damage that would occur to standard tines.

Q9. Do you provide technical support or installation guides for the round baler price listed?

A9. Yes, the round baler price includes a comprehensive English manual, video installation guides, and 24/7 online technical support to ensure you can set up and operate the machine confidently.

Q10. Can I order a mixed container with mini round baler for sale alongside this heavy-duty model?

A10. Absolutely. We encourage mixed orders to optimize shipping costs. You can combine the heavy-duty 9YG-1.0C with our mini round baler models to cater to different customer segments in your market.

編集者: PXY