Baler bulat EP-9YG-2.24D

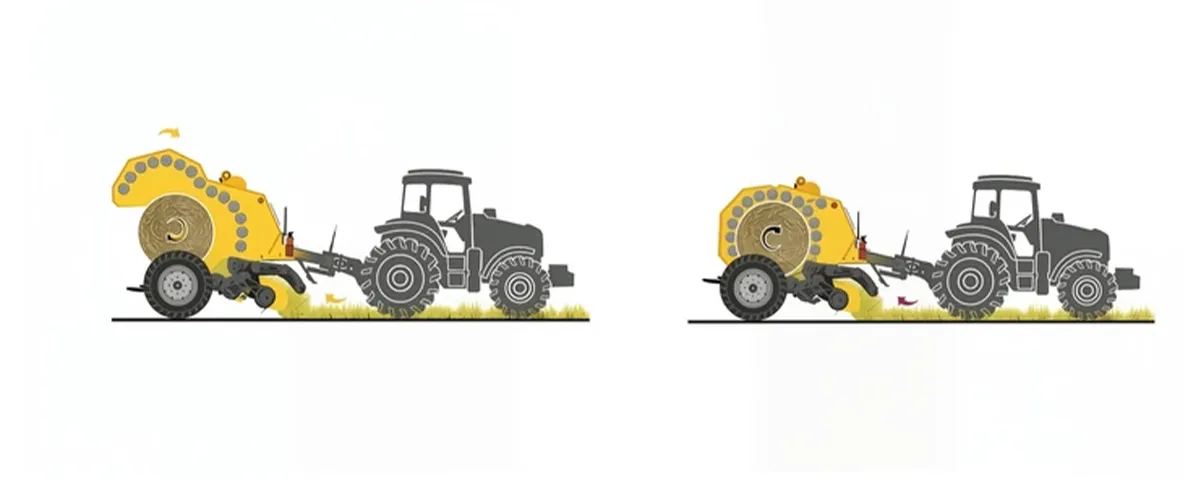

The 9YG-2.24D Round baler is a versatile solution designed to tackle the common challenges of straw collection: blockages and high power consumption. Unlike traditional machines, this straw baler features an innovative camless pickup mechanism and a proprietary axial flow feeding system. This “semi-forced” feeding design ensures a significant intake of coarse crops like corn stalks, wheat, and rice straw. With a 2240mm wide pickup and a productivity of 40-100 bales per hour for professional corn stalk recovery and forage round baler operations.

1.Key selling points of the 9YG-2.24D Round baler.

Innovative Feeding System: This model employs a self-developed "axial flow" semi-forced feeding mechanism, optimizing the feed transport path. This design significantly reduces the risk of crop clogging, ensuring smooth operation even when handling coarse corn stalks or damp crops.

Advanced Technology: The machine abandons the traditional cam disc and guard ring structure, adopting a more advanced camless pickup design. The simplified mechanical structure greatly reduces wear points on parts, effectively lowering the failure rate and subsequent maintenance costs, and significantly extending the service life of core components.

High-Capacity Wide Pickup: Equipped with a 2240mm ultra-wide pickup, it can handle large stalks of grass left by combine harvesters in a single pass, eliminating the need for repeated back-and-forth movements. This wide design increases productivity to 40-100 bales per hour, nearly doubling the efficiency of traditional models. It boasts exceptional versatility, achieving efficient and clean pickup of wheat, rice, soybean stalks, and natural forage.

2. Why the 9YG-2.24D Round Baler is Your Efficient Harvesting Solution?

Innovative Camless Pickup System:

Technical Description: This design abandons the traditional cam-disc structure, adopting a unique camless and ringless design.

Benefits: The mechanical structure is simpler, reducing potential failure points. Compared to traditional structures, it significantly reduces component wear and maintenance costs, and provides smoother operation.

Axial Flow Semi-Forced Feeding:

Technical Description: Employs a semi-forced feeding method, optimizing the path of forage entering the compression chamber.

Benefits: Significantly reduces the probability of forage blockage. Maintains smooth feeding even when crops are wet or have uneven density, minimizing downtime for cleaning.

3.Technical Specifications of 9YG-2.24D Round baler.

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9YG-2.24D Round Baler |

| 2 | Hitch Type | / | Trailed (Traction) |

| 3 | Pickup Width | mm | 2240 |

| 4 | Pickup Structure Type | / | Spring Tooth Type |

| 5 | Feeding Structure Type | / | Tine Roller + Roller Type |

| 6 | Compression Chamber Mechanism | / | Roller Type |

| 7 | Compression Chamber Width | mm | 1400 |

| 8 | Compression Chamber Diameter | mm | Φ1200 |

| 9 | No. of Compressing Components | pc | 18 (Rollers) |

| 10 | Compression Roller Diameter | mm | Φ222 |

| 11 | Binding Method | / | Net Wrap |

| 12 | Matched Power | kW | 55-100 |

| 13 | Structural Weight | kg | 3922 |

| 14 | PTO Speed | r/min | 720 |

| 15 | Overall Dimensions (L×W×H) | mm | 4110×3010×2450 (Working State) |

| 16 | Bale Density Control | / | Sensor Control |

| 17 | Bale Size (Diameter × Width) | mm | Φ1300×1400 |

| 18 | Bale Density | kg/m³ | 100~200 |

| 19 | Productivity | Bales/h | 40~100 |

| 20 | Wheel Track | mm | 2600 |

| 21 | Operating Speed | km/h | 5-35 |

| 22 | Net Wrap Specification (L×W) | m | 2000X1.4 m / Roll |

4. 9YG-2.24D Round baler directly addresses market demand.

Application Scenarios in Russia

1. Clog Prevention During the "Harvest Season" in the Volga River Basin and Central Region

Background: Central Russia and the Volga River basin are core grain-producing areas, but the autumn harvest season is often accompanied by rain, resulting in high moisture content in straw (wheat, barley).

Pain Point: Damp straw easily clumps at the picking and feeding inlets, causing frequent blockages in ordinary balers. Clearing these blockages is not only tiring but also wastes valuable harvest time.

Advantages of the 9YG-2.24D: "Axial Flow Feeding" semi-forced feeding system:

Forces damp, uneven straw into the compression chamber smoothly, greatly reducing the chance of clogging. For Russian farmers racing against the weather, "no blockages" is the greatest efficiency.

2. Low-Maintenance Operations in Siberia and the Far East

Background: Farms are far from repair stations, resulting in slow parts delivery.

Pain Point: The more complex the machine, the more prone it is to breakdowns. Traditional pickups' cam tracks and bearings are vulnerable to damage under dusty or high-intensity conditions, and repairs are extremely difficult once damaged.

Advantages of the 9YG-2.24D: Camless Pickup:

Eliminates the complex cam structure. The mechanical structure is extremely simple, with fewer parts, meaning fewer potential points of failure. Simple, robust, and easy to repair.

3. Large-scale Straw Removal from Vast Plains

Background: Russian farmland is vast, with wide and long straw strips left after combine harvesters.

Pain Point: Narrow-width pickups require constant adjustment to align the straw strips, resulting in low efficiency.

Advantages of the 9YG-2.24D: 2240mm Wide Pickup Width + High Throughput:

This width allows for the simultaneous processing of wide straw strips from large combine harvesters. With a high productivity of 40-100 bundles per hour, it is ideal for rapid advancement in large, flat fields, reducing tractor fuel consumption and labor hours.

Among the S9000 series, the 9YG-2.24D-Round baler-Transcend is more recommended.

Application Scenarios in Kazakh

1. Large-scale Wheat Straw Recovery in the Northern Grain Belt

Background: Northern Kazakhstan (Kostanay, North Kazakhstan, Akmola region) is a world-class wheat-producing area. Every year after harvest, millions of tons of straw are left in the fields.

Pain Points:

Short Harvesting Time: Winters arrive very early in the north, requiring rapid clearing of straw from the fields before the snow season.

Clogging Issues: Combine harvesters operate quickly, leaving behind thick straw strips that are often damp with morning dew, easily clogging ordinary balers.

Advantages of the 9YG-2.24D Application:

Axial Flow Semi-Forced Feeding: This technology forces the thick wheat straw strips into the compression chamber, significantly reducing downtime due to clogging.

2240mm Wide Pickup: Perfectly matches the wide strips of hay left by large combine harvesters, allowing for a single pass without the need for patching, making it a good alternative.

2. Remote Steppe Hay Harvesting

Background: Kazakhstan boasts the world's largest dry steppe, and livestock farming (horses, sheep, cattle) is mostly conducted in remote areas far from cities.

Pain Point: "Difficulty in Maintenance." Deep in the steppe, if the machine's cam disc slide wears out or the bearing breaks (a common failure of traditional pickups), farmers may need to drive hundreds of kilometers to buy parts, or even wait a long time.

Advantages of the 9YG-2.24D: Camless Pickup(Без кулачковый подборщик):

Eliminating the complex cam disc and bearing assembly means fewer points of mechanical failure. The simpler the structure, the more robust it is, making it more suitable for this kind of extensive operating environment where "once it breaks, there's no one to fix it." We also provide spare parts replacement services. 3. Cost-Effective Winter Fodder Reserve for Livestock

3. Cost-Effective Winter Fodder Reserve

Background: Kazakhstan experiences long, harsh winters, requiring livestock to maintain large reserves of hay.

Advantages of the 9YG-2.24D:

Low Power Consumption and High Efficiency: Compared to traditional models, this machine's feeding mechanism reduces power consumption. This means farmers can easily operate it with a medium-sized tractor (starting from 55kW), saving on expensive diesel fuel and reducing operating costs.

5. Customer Reviews and Case Studies of 9YG-2.24D Round Baler.

Client1 Profile: Kazakh

Customer Reviews:

"Our harvest window is very short before the snow. In the past, we would waste several hours every day clearing blockages from our old balers whenever the wheat straw got damp in the evening. Their axial flow feeding system is impressive. It feeds the straw smoothly without clogging. It allows us to keep operating efficiently at the most critical moments."

Client2 Profile: Mongolia

Customer Reviews:

"Buying replacement parts is a hassle for our ranch. That's why I chose this model. Its camless pickup mechanism has fewer moving parts, no easily worn cam tracks, and no need to replace damaged bearings. It's a simple, durable, and reliable machine. For the prairie region, reliability is more important than fancy features, making it the top choice."

6.Application Scenarios of the 9YG-2.24D Round baler.

1. Russia – Targeting Wet Climates and Vast Farmlands

Scenario 1: Wet Wheat Straw Harvesting in the Volga Region

Scenario 2: Remote Siberian Hay Harvesting

Scenario 3: Sunflower/Corn Stalks as Feed in the South

2. Kazakhstan – Targeting Large-Scale Grain Storage and Low-Cost Operations

Scenario 4: Northern Grain Belt Straw Removal

Scenario 5: Cost-Effective Steppe Operation in Steppe Pastures

Scenario 6: Emergency Winter Fodder Reserve

3. South Korea – Targeting Rice and Silage

Scenario 7: Post-Harvest Rice Straw Collection Scenario 8: Winter Ryegrass Silage Making

4. Brazil – Targeting Biomass Energy and Tropical Crops

Scenario 9: Sugarcane Straw for Biomass Energy Recovery

Scenario 10: Corn Stover in ILPF Systems

Scenario 11: Tropical Brachiaria Grass Harvesting

5. Russia – Targeting Cash Crops and Fiber Crops

Scenario 12: Flax/Hemp Straw Recovery

6. Kazakhstan – Targeting High-Quality Forage Export

Scenario 13: High-Quality Alfalfa Baling

7. Brazil – Targeting Cover Crops and No-Till Agriculture

Scenario 14: Cover Crop Clearing Before Soybean Planting (for No-Till Farming)

8. South Korea – For Lodging Crops and Emergency Harvesting

Scenario 15: Emergency Harvesting of Lodging Rice/Wheat (Harvesting Lodged Crops)

9. General Cross-Regional Scenario – For Cross-Regional Operation Service Providers

Scenario 16: High-Intensity Mobile Operations by Cross-Regional Contractors (Contract Baling Services)

7.The farm-balers-9YG-2.24D Round baler after-sales guarantee and support system.

1. Spare parts repair and replacement.

2. Every product comes with a free user manual.

3. After-sales service and warranty/maintenance.

4. Products delivered globally.

5. Professional language teams communicate to understand your needs.

6. Product training.

7. Every year during the grass-cutting season, we conduct follow-ups and market surveys for every herder who has purchased and used our products, and provide technical training for first-time users.

8.Application Scenarios of the 9YG-2.24D Round baler.

We’ve outfitted our modern production bases with cutting-edge equipment, such as:

·ISO9001 Quality Management System Certification

·CNC laser cutting machines

·Laser & Plasma Cutting Systems

·Automated Assembly Lines

·Electrostatic spraying production lines Systems

·Digital Factory & Industrial Software

·Dynamometer Testing Stations and so on

Tentang kami

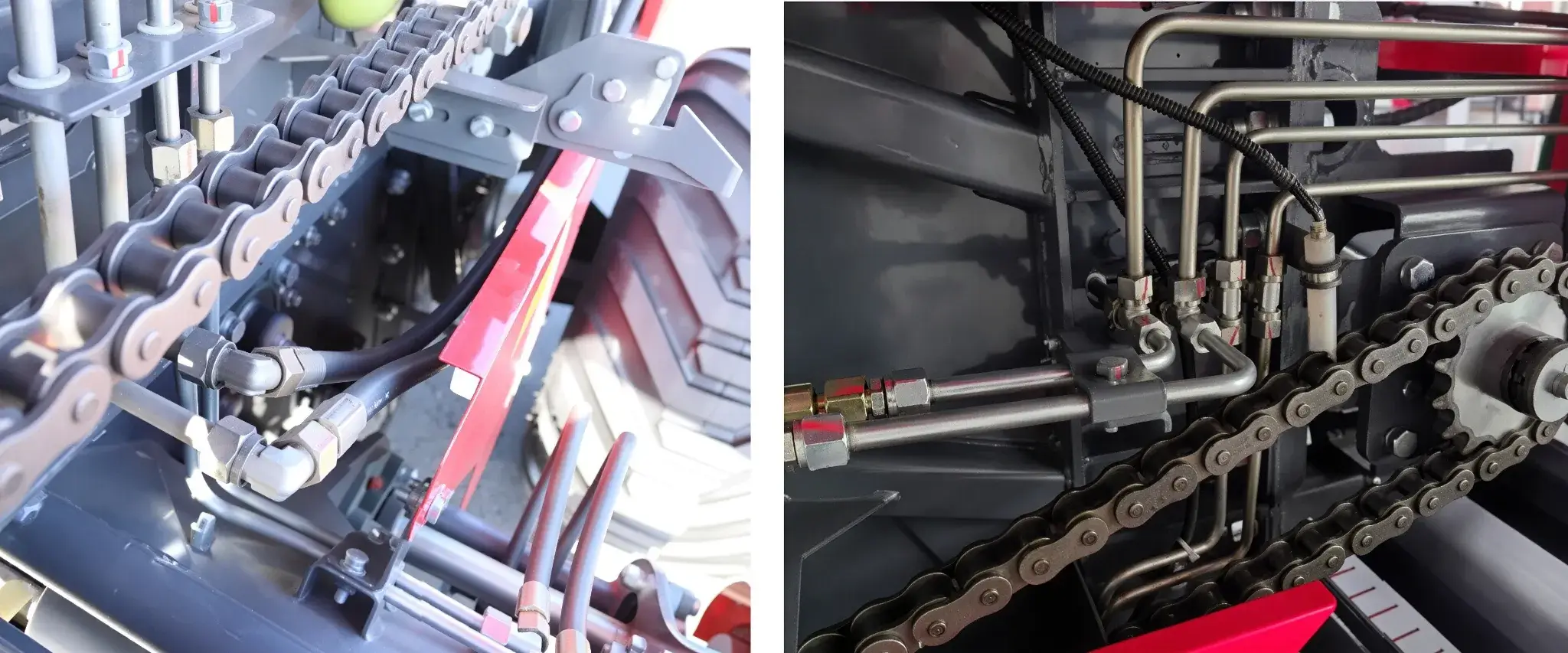

9.Related components.

For those searching for "Drive Chain for round balers" or "replacement Drive Chain for hay baler," our solution provides the precision and reliability needed for sustainable farming.

We also offer spare parts, including PTO Shaft & Tractor Gearbox, Drive Chain & Sprocket, Sheave & Pulley, Pickup Shaft Bearings & Shaft Collar, Hay Picker Shaft & Hay Picker Stand, Skids & Abrasion Plates, Teeth & Hay Picker Springs.

Hubungi kami and we'll send you a detailed PDF of available replacement parts.

FAQ:

Q1.What other replacement parts do we provide?

A1.Our replacement parts include:

1. PTO shaft & agricultural gearbox assemblies

2. Chains & sprockets (heavy-duty roller chain drives)

3. Belts & pulleys/tensioning mechanism parts

4. Bearings, bearing housings, bushings & shaft locks

5. Wear parts for hay picking systems: spring teeth, hay picking shafts, slippers, wear plates, etc.

6. Knotting/wrapping system accessories: knotter gears, blades, friction plates, guide wheels, etc.

7. Baling chamber/compacting system accessories: rollers, roller sprockets, liners, pulleys, shafts, etc.

8. Hydraulic & control components: hydraulic cylinders, O-rings, hoses, control cables, and accessories.

Q2.Net Wrap vs Twine: Which is better for silage and hay?

A2.Net wrap is generally superior for both speed and preservation. The 9YG-2.24D features an automatic net wrap system that binds a bale in just a few seconds (compared to minutes with twine). Net wrapping holds the bale shape tighter, sheds water better for outdoor storage, and reduces leaf loss in hay, making it the preferred choice for high-quality silage and forage.

Q3.Can the 9YG-2.24D baler handle tough crops like corn stalks?

A3.Yes! While many light-duty balers struggle with coarse stalks, the 9YG-2.24D is built with a reinforced chassis and a powerful feeding roller system specifically for corn stalk recovery. It effectively packs crops , making it ideal for biomass energy or livestock bedding.

Q4.How heavy are the bales produced by the 9YG-2.24D?

A4.The bale weight depends on the crop type and moisture content. It features a sensor-controlled density system that allows operators to adjust the compression, achieving densities of 100-200 kg/m³ to optimize transport costs.

Q5.Where can I buy parts for the 9YG-2.24D?

A5.Send a form to obtain detailed component PDF models.

Editor: PXY