EP-9YG-2.24D-Pengikat bulat-Klasik

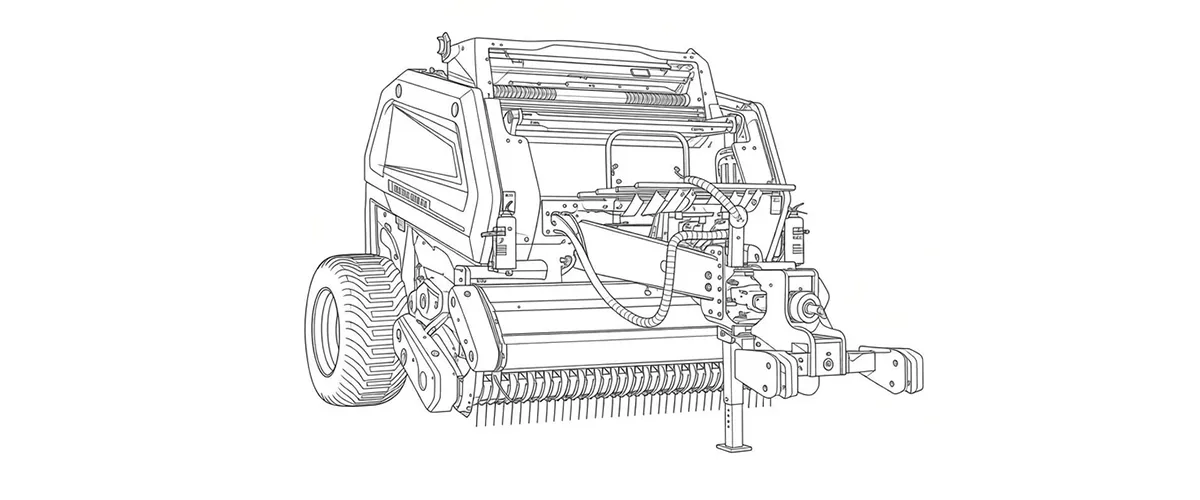

The 9YG-2.24D-Round baler-Classic, equipped with a roller-type compression chamber and sensor-controlled bale density, it produces uniform bales (φ1300×1400mm) with a density of 100-200 Kg/m³, facilitating storage and transportation while reducing space occupation. The dual-sided sprocket drive and heavy-duty gearbox ensure stable operation even on undulating terrain, lowering failure rates and extending service life. With a productivity of 40-100 bales per hour, it significantly improves working efficiency and reduces labor intensity for users.

1. Product Highlights of the 9YG-2.24D-Round baler-Classic.

More Reliable Traction Drive:

Our 9YG-2.24D-Round baler-Classic, equipped with a self-developed dual universal joint driveshaft and an additional safety torque driveshaft, can effectively protect all machine components and solve the problem of drivetrain jamming during turning operations on small plots for traction-type round balers.

Hydraulic and Transmission Optimization:

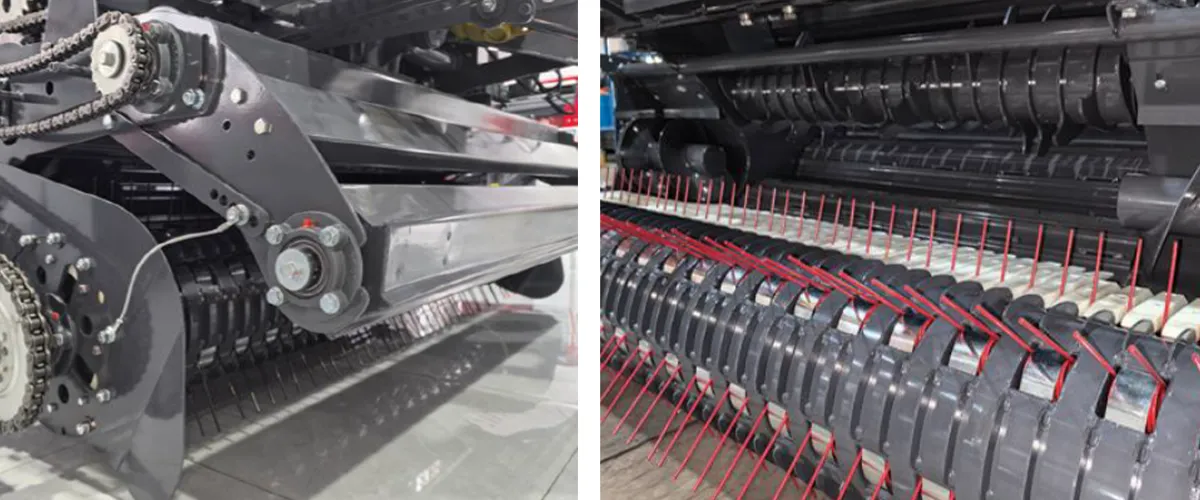

The hydraulic system uses H-type sleeve connectors, supporting higher pressure and faster bin opening and closing speeds; the rear bin is equipped with a cushioning cylinder to reduce mechanical damage from bin closure vibrations; combined with a reinforced gearbox, the transmission torque is increased, and the rear bin adopts a dual-side sprocket drive design for smoother and more efficient baling operations.

Strong Adaptability:

The traction-type hitch design, paired with a stable transmission structure, is compatible with various crop residues and forage baling, making it suitable for conventional field work scenarios.

2. Technical Specifications of 9YG-2.24D-Round baler-Classic.

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9YG-2.24D Round Baler (S9000 Classic) |

| 2 | Hitching Method | / | Traction Type |

| 3 | Pickup Width | mm | 2240 |

| 4 | Pickup Structure Type | / | Spring Tooth Type |

| 5 | Feeder Structure Type | / | Fork Roller + Drum Type |

| 6 | Compression Chamber Baling Mechanism Type | / | Drum Type |

| 7 | Compression Chamber Width | mm | 1400 |

| 8 | Compression Chamber Diameter | mm | φ1200 |

| 9 | Number of Pressing Working Parts | pcs | 18 (Drums) |

| 10 | Pressing Drum Diameter | mm | φ222 |

| 11 | Binding Method | / | Net Wrapping |

| 12 | Supporting Power | kw | 55-100 |

| 13 | Structural Mass | kg | 4312 |

| 14 | Power Output Shaft Speed | r/min | 720 |

| 15 | Overall Dimensions (L×W×H) | mm | 4470×3010×2370 (Working State) |

| 16 | Bale Density Control | / | Sensor Control |

| 17 | Bale Size (Diameter×Width) | mm | φ1300×1400 |

| 18 | Bale Density | Kg/m³ | 100-200 |

| 19 | Production Rate | Bales/h | 40-100 |

| 20 | Wheelbase | mm | 2600 |

| 21 | Operating Speed | Km/h | 5-35 |

| 22 | Net Specification (L×W) | / | 2000X1.4 m/Bale |

3. Directly Addressing Market Demand:

- Growing Demand Driven by Livestock Farming

The steady expansion of dairy and beef cattle farming in Korea creates consistent demand for high-quality forage, including silage and dry hay. The 9YG-2.24D Transcend Round Baler is ideally suited for use on ranches and at feed processing facilities. - Wide Crop Compatibility

Our baler efficiently handles a broad range of crops, including:

wheat, rice straw, reed, cotton stalks, alfalfa, pasture grass, corn silage, sugarcane residue, and more. - Aging Rural Population Calls for Labor-Saving Equipment

With over 40% of Korean farmers aged 65 or older, the government actively subsidizes "labor-saving" and "smart" agricultural machinery. Our 9YG-2.24D-Round Baler directly addresses this need—featuring "reduced operator fatigue"—making it perfectly aligned with current market demands. - Proactive After-Sales Service

During each annual haying season, we conduct follow-up visits and market surveys with every customer. First-time users receive hands-on technical training, and all machines come with a comprehensive warranty and repair support. - Customized Solutions

We offer different machine configurations tailored to local transportation regulations and field conditions in your region. - Parts & Maintenance Support

We provide full replacement parts service. If any components of your baler wear out and require replacement, please contact us. A detailed list of available spare parts is provided below.

3. Why does the Russia market need the 9YG-2.24D-Round baler?

In Russia's agriculture sector, where declining grain production and harsh weather conditions like early frosts limit yields, the 9YG-2.24D Round Baler Classic serves as a practical farm baler manufacturer option to manage crop residues effectively. With a 2240mm pickup width and a production rate of 40-100 bales per hour, this traction-type baler helps farmers compress straw and forage into dense bales of 100-200 Kg/m³, reducing spoilage during long storage periods in variable climates.

It cuts labor needs through sensor-controlled density and smooth turns in uneven fields via its double universal joint driveshaft, allowing better resource use without added manpower. It supports cost savings by minimizing waste and improving feed transport, aiding sustainable practices amid economic pressures.

4. Why choose us?

For ranch owners facing heavy straw processing tasks and labor shortages, our 9YG-2.24D round baler is a machine designed to alleviate these pressures. As a professional round baler supplier, we fully consider the actual agricultural scenarios in various locations. Whether handling rice straw, barley, or corn stalks in scattered fields or processing feed for livestock farms, this agricultural baler provides stable and reliable performance. We offer different models based on varying local transportation specifications.

The 2240 mm pickup width covers large areas in one pass, enhancing work efficiency. The pickup structure gently grasps the straw to avoid material damage, while the drum-type compression chamber forms round bales that are loose inside and tight outside. Equipped with sensor-controlled density adjustment, it allows control of 100-200 kg/m³ density as needed—facilitating stacking, transportation, and unloading.

5. Customer Reviews and Case Studies of 9YG-2.24D-Round Baler-Classic.

Client1 Profile: Russian

Customer Reviews:

"As a pasture owner in Siberia, we’ve used the 9YG-2.24D round baler for two years. This machine demonstrates stable performance in cold climates, particularly well-suited for the snowy and muddy conditions here. The dual gearbox design allows seamless turns on small plots without cutting power, significantly improving operational efficiency. With a productivity rate of 40–100 bales per hour, we’ve harvested 20% more hay compared to previous years while saving substantial labor."

Client2 Profile: Kazakhstan

Customer Reviews:

"Our main crops are forage grass and wheat straw. The pickup width of this round baler is extremely practical—it allows us to complete large-area operations quickly. The sensor-controlled bale density ensures consistent bale quality, which our previous machine couldn’t achieve. This model is more durable, and even allows individual replacement parts (haha!)—a huge plus! It has now become our pasture’s mainstay equipment."

6. Application Scenarios of the 9YG-2.24D-Round baler-Transcend.

I. Forage Harvesting and Storage Scenarios in Grasslands and Pastures

The bale density is adjustable between 100-200 Kg/m³, which saves barn space when stacked and stored. It is convenient to unpack bales for feeding cattle and sheep in winter. Suitable for the daily forage harvesting and storage needs of family pastures and medium-sized to large-scale pastures, a single person can operate it to replace multiple workers, greatly reducing labor intensity.

Crops that can be baled include wheat, rice, cotton, pasture, corn silage, alfalfa, sugarcane, and reeds.

II. Crop Straw Resource Utilization Scenarios

It solves the pain points of straw burning pollution and high labor costs for transportation. It can directly turn straw into tight round bales in the field. The net wrapping can resist wind, sand, and rain erosion, and the straw will not mildew easily after 6 months of storage. The treated straw can be converted into cattle farm feed, biomass fuel raw materials, etc.

III. Silage Feed Preparation Scenarios in Livestock Farms

The high productivity of 100 bales per hour can meet the silage harvesting and storage needs of livestock farms during peak seasons, and is suitable for large-scale feed preparation work in large dairy farms and beef cattle farms.

IV. Operating Scenarios in Special Environments and Plots

Low-temperature Operation Scenarios: Cold regions such as Krasnoyarsk Krai, Russia. The transmission system can adapt to the low-temperature environment, start and operate stably, and ensure straw/forage harvesting and storage in winter.

V. Emergency Response and Disaster Relief Scenarios

In regions prone to floods, wildfires, or droughts, the 9YG-2.24D can play a critical role:

- Post-fire recovery: Rapidly clear and bundle charred vegetation for safe disposal.

- Flood zones: Compact waterlogged crop residues to prevent disease spread.

- Drought-stricken areas: Preserve scarce forage by creating long-lasting bales for livestock.

6. The farm-balers-9YG-2.24D-Round Baler-Transcend after-sales guarantee and support system.

1. Spare parts repair and replacement.

2. Every product comes with a free user manual.

3. After-sales service and warranty/maintenance.

4. Products delivered globally.

5. Professional language teams communicate to understand your needs.

6. Product training.

7. Every year during the grass-cutting season, we conduct follow-ups and market surveys for every herder who has purchased and used our products, and provide technical training for first-time users.

7. About us

We’ve outfitted our modern production bases with cutting-edge equipment, such as:

·Pensijilan Sistem Pengurusan Kualiti ISO9001

·CNC laser cutting machines

·Laser & Plasma Cutting Systems

·Automated Assembly Lines

·Electrostatic spraying production lines Systems

·Digital Factory & Industrial Software

·Dynamometer Testing Stations and so on

Tentang kami

8. Related components.

Related components: Tractor Gearbox

Our tractor gearbox replacement is engineered for easy installation, fitting seamlessly into the baler's traction-type system. As a trusted supplier of round baler parts, we offer this gearbox to help reduce maintenance costs and improve overall productivity. Whether you're dealing with wheat straw or corn stalks, this component ensures your fixed chamber round baler performs reliably season after season.

For those searching for "tractor gearbox for round balers" or "replacement gearbox for hay baler," our solution provides the precision and reliability needed for sustainable farming. Hubungi kami for compatible models and expert advice on maintaining your round baler equipment.

9. FAQ

Q1:What other replacement parts do we provide?

A1.Our replacement parts include:

1. PTO shaft & agricultural gearbox assemblies

2. Chains & sprockets (heavy-duty roller chain drives)

3. Belts & pulleys/tensioning mechanism parts

4. Bearings, bearing housings, bushings & shaft locks

5. Wear parts for hay picking systems: spring teeth, hay picking shafts, slippers, wear plates, etc.

6. Knotting/wrapping system accessories: knotter gears, blades, friction plates, guide wheels, etc.

7. Baling chamber/compacting system accessories: rollers, roller sprockets, liners, pulleys, shafts, etc.

8. Hydraulic & control components: hydraulic cylinders, O-rings, hoses, control cables, and accessories.

Q2:What to look for when buying used round balers?

A2.Inspect the transmission system. We have equipped it with a self-developed dual decimal drive shaft and a safety torque protection device. The universal power output shaft speed is 720 rpm to prevent jamming. Therefore, when considering a used machine, be sure to check the internal parts.

Q3:How does a round baler work for hay making?

A3.When making hay, the 9YG-2.24D gently picks up the straw using a spring-tooth picker and a toothed roller feeder to avoid damage. The compression chamber is 1400 mm wide, forming bales that are loose on the inside and tight on the outside, with a diameter of φ1300×1400 mm. It has a production rate of 40-100 bales/hour and is suitable for processing rice straw or corn stalks.

Q4:Which round baler to buy for forage harvesting?

A4.We recommend the 9YG-2.24D Round Baler - Transcend model. Its wire-wrapping system and 222 mm diameter rollers ensure moisture protection for the bales. The heavy-duty gearbox and dual-side sprocket drive ensure a smooth baling process, suitable for barley or corn stalks, reducing vibration damage.

Most importantly, the 9YG-2.24D-Round baler-Transcend model adds a corner gearbox compared to the classic model.

Q5:Can I make small bales with a round baler?

A5.Sure. The 9YG-2.24D supports flexible adjustment of bale size. Through sensor-controlled density, smaller bales (density 100-200 kg/m³) can be produced when needed. The bale netting is 2000 x 1.4 meters per bale, allowing for resumption of work after interruptions and preventing waste.

Editor:PXY