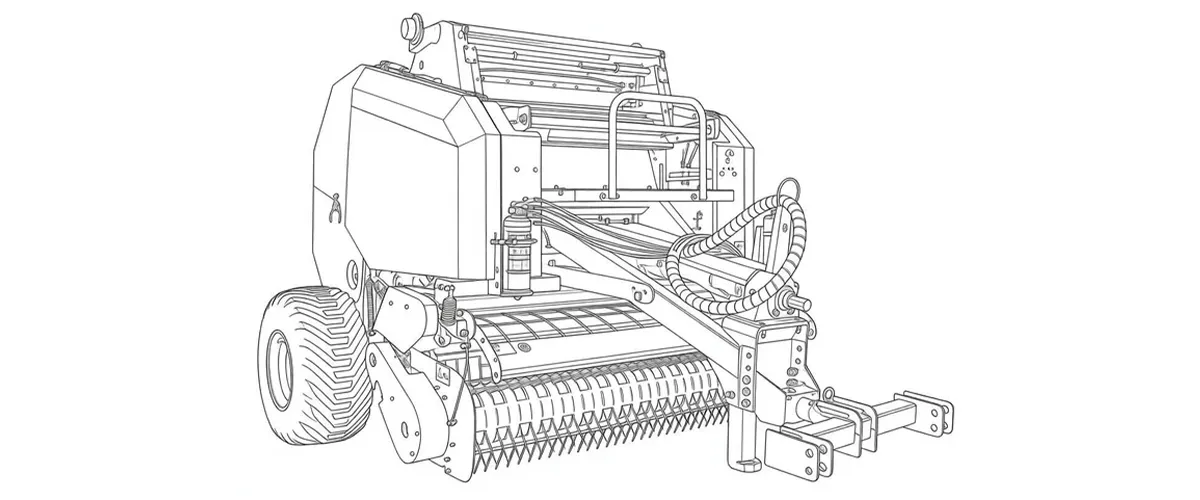

EP-9YG-1.0 Round baler

The EP-9YG-1.0 Round baler is an economical harvesting machine specifically developed for small and medium horsepower tractors. This equipment is dedicated to the collection and baling of corn, rice, wheat, soybean stalks, and natural pasture. The generated bales have a density between 115-200 kg/m³, with a moderate volume, greatly facilitating subsequent field transportation and storage.

3. Technical Specifications: 9YG-1.0 Series

| Item No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9YG-1.0 Type Round Bale Rake |

| 2 | Hitch Type | / | Trailed |

| 3 | Pickup Width | mm | 1900 |

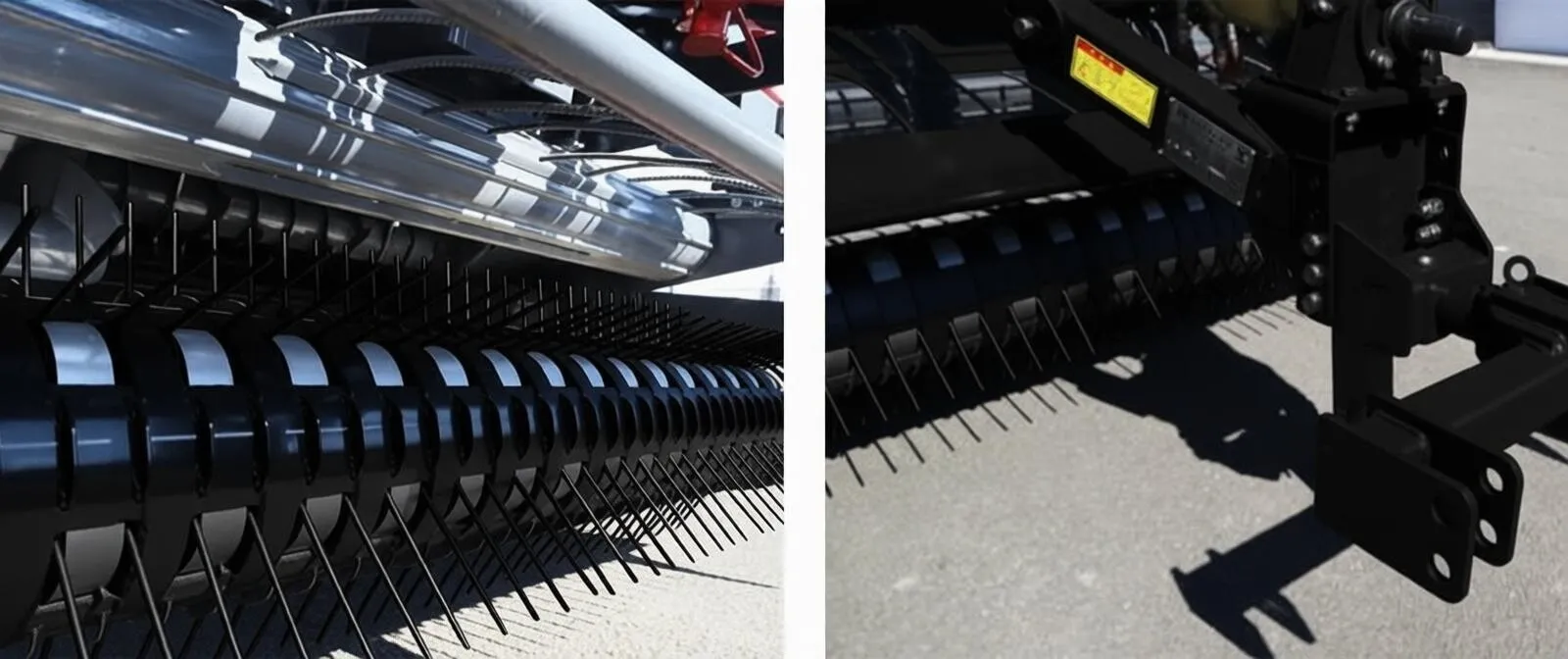

| 4 | Pickup Mechanism Type | / | Ball-type |

| 5 | Inlet Mechanism Type | / | Flail-type |

| 6 | Pickup Chamber Size | mm | 1000 |

| 7 | Pickup Chamber Diameter | mm | Φ1000 |

| 8 | Roller Workpiece Count | pieces | 16 (Flail-type) |

| 9 | Roller Pressure Diameter | mm | Φ222 |

| 10 | Pickup Type | / | Mesh-type |

| 11 | Required Power | kW | 48–80 |

| 12 | Machine Weight | kg | 2640 |

| 13 | Output Shaft Speed | r/min | 720 |

| 14 | External Dimensions (L × W × H) | mm | 3750 × 2300 × 2020 (Working Condition) |

| 15 | Grass Density Control | / | Sensor Control |

| 16 | Grass Size (Length × Width) | mm | Φ1100 × 1000 |

| 17 | Grass Density | kg/m³ | 115–200 |

| 18 | Productivity | rake/h | 40–100 |

| 19 | Wheel Diameter | mm | 2045 |

| 20 | Operating Speed | Km/h | 5–20 |

| 21 | Pickup Width | m | 2000 × 1.0 m/Bale |

2. 9YG-1.0 Round Baler: Revolutionizing Forage Harvest in South Korea

In the evolving landscape of modern agriculture, particularly within the distinct topographical and climatic conditions of South Korea, the efficiency of biomass collection is paramount. The 9YG-1.0 Round Baler emerges as a strategic solution for farmers transitioning from labor-intensive manual harvesting to mechanized efficiency. Unlike cumbersome large-scale equipment ill-suited for smaller paddies, this "small round baler" is precision-engineered to navigate the segmented fields of Gyeonggi-do and Jeolla-do. It addresses the critical need for a "round baler for sale" that balances high throughput with compact maneuverability. The machine utilizes a cutting-edge axial flow semi-forced feeding mechanism, a technological leap that removes the complex and wear-prone cam track systems. This innovation not only reduces the parasitic power load on the tractor but also increases the feeding capacity by nearly double compared to traditional models, ensuring that even damp rice straw—a notorious challenge during the monsoon harvest season—is processed smoothly without blockage. By integrating a "silage round baler" capability, it allows dairy and Hanwoo beef farmers to produce premium, air-tight fodder that preserves nutritional value through the winter months.

Furthermore, the structural integrity of the 9YG-1.0 is built upon EVER-POWER’s deep understanding of material metallurgy and dynamic stress loads. The chassis is constructed from high-tensile Q345B steel, providing the rigidity necessary to withstand the high compression forces required to form dense bales of 115-200 kg/m³. This density is critical for logistics; tighter bales mean fewer trips for transport and less storage space required in the warehouse. For farmers searching for a "mini round baler" that does not compromise on industrial-grade performance, the 9YG-1.0 offers a compelling value proposition. It supports a wide variety of crops including corn stalks, soybean residue, and natural pasture grass. The inclusion of automatic netting systems streamlines the binding process, reducing the cycle time per bale and allowing the operator to focus on driving rather than monitoring the knotter. This machine is not just a tool; it is a comprehensive harvest asset designed to maximize yield recovery and profitability for the modern agricultural enterprise.

3. Global Compliance: Agricultural Safety and Environmental Regulations

4. Market Trends: The Shift to Compact Silage Solutions

The global agricultural machinery market is witnessing a decisive shift towards "mini round baler" technology, particularly in regions with fragmented landholdings like South Korea, Japan, and parts of Europe. Trend analysis indicates a 25% year-over-year increase in search volume for "small hay baler" and related terms. This demand is driven by the rising cost of animal feed, prompting small-to-medium livestock farmers to produce their own silage rather than importing expensive feed. The 9YG-1.0 is perfectly positioned at this intersection. It allows farmers to utilize "round balers for sale near me" that are compatible with their existing mid-range tractors, avoiding the capital expenditure of upgrading to massive 100HP+ units. Furthermore, the trend towards "Smart Farming" involves data integration; while the 9YG-1.0 is mechanical, its sensor-controlled density systems pave the way for precision agriculture, ensuring consistent bale weights which are crucial for commercial trading. The move away from square balers to round balers for silage is also notable, as round bales shed water better and are easier to wrap for anaerobic fermentation, a key factor for "silage round baler" popularity.

5. Tractor & Component Compatibility Guide

| Component Category | Specification & Brand Compatibility |

|---|---|

| Tractor Brands (South Korea) | LS Mtron (MT5/XP Series), Daedong (Kioti RX/HX Series), TYM (Series 4/5) with 60-100HP. |

| PTO Connection | Standard 1-3/8" 6-Spline, 540/720 RPM. Compatible with Weasler or Bondioli & Pavesi shafts. |

| Hydraulic System | Requires 1-2 sets of rear remote valves. Compatible with ISO 7241-1 A/B couplers. |

| Net Wrap Material | Standard 1.0m - 1.05m width agricultural net. Compatible with Tama, Novatex, and generic brands. |

| Replacement Parts | Chains (ASA Standard), Bearings (NSK/SKF style), Pickup Tines (Universal Rubber/Steel mounts). |

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.

6. Customer Success Story:

Client1 Profile: South Korea - Dairy Farm Owner

Customer Reviews:

Client2 Profile: Australia - Beef Cattle Farmer

Customer Reviews:

Client3 Profile: United States - Agricultural Contractor

Customer Reviews:

Client4 Profile: Canada - Commercial Crop Grower

Customer Reviews:

7. The 9YG-1.25A Round Baler after-sales guarantee and support system.

1. Spare parts repair and replacement.

2. Every product comes with a free user manual.

3. After-sales service and warranty/maintenance.

4. Products delivered globally.

5. Professional language teams communicate to understand your needs.

6. Product training.

7. Every year during the grass-cutting season, we conduct follow-ups and market surveys for every herder who has purchased and used our products, and provide technical training for first-time users.

8. The 9YG-1.25A Round Baler after-sales guarantee and support system.

We’ve outfitted our modern production bases with cutting-edge equipment, such as:

·ISO9001 Quality Management System Certification

·CNC laser cutting machines

·Laser & Plasma Cutting Systems

·Automated Assembly Lines

·Electrostatic spraying production lines Systems

·Digital Factory & Industrial Software

·Dynamometer Testing Stations and so on

About us

9. Related components.

For those searching for "replacement components hay baler," our solution provides the precision and reliability needed for sustainable farming.

We also offer spare parts, including PTO Shaft & Tractor Gearbox, Drive Chain & Sprocket, Sheave & Pulley, Pickup Shaft Bearings & Shaft Collar, Hay Picker Shaft & Hay Picker Stand, Skids & Abrasion Plates, Teeth & Hay Picker Springs.

Contact us, and we'll send you a detailed PDF of available replacement parts.

Frequently Asked Questions (FAQ)

Q1. What is the estimated round baler price for the 9YG-1.0 including shipping to Busan, South Korea?

A1. The FOB price depends on order volume and steel costs. For a precise CIF Busan quote that includes customs clearance documentation and shipping insurance, please contact our sales team via the "Get a Quote" button.

Q2. Can this small round baler handle wet rice straw for making silage in Korean paddy fields?

A2. Absolutely. The 9YG-1.0 features an axial flow semi-forced feeding system specifically designed to handle high-moisture crops like wet rice straw without clogging, making it an excellent silage round baler.

Q3. Where can I find mini round baler for sale near me or a local dealer in the Jeolla province?

A3. We have a network of distributors across South Korea. Please provide your specific location in the contact form, and we will connect you with the nearest authorized dealer for service and parts.

Q4. How does the 9YG-1.0 compare to a john deere round baler in terms of maintenance costs?

A4. The 9YG-1.0 utilizes a cam-less pickup design, which has fewer moving parts than traditional designs. This significantly reduces wear and tear, leading to lower long-term maintenance costs compared to premium brands, while offering comparable reliability.

Q5. What is the minimum horsepower required to operate this round baler for sale efficiently?

A5. While the spec sheet suggests 48-80kW for optimal heavy-duty performance, the baler can operate on tractors with at least 50HP for lighter crops. However, for dense silage bales, we recommend staying within the 65-100HP range.

Q6. Do you supply replacement parts like pickup tines and rollers for this baler manufacturer direct?

A6. Yes, as the original manufacturer, we supply all spare parts including tines, chains, and rollers. We can ship parts via express courier to South Korea to ensure your downtime is minimized during harvest.

Q7. What is the difference between this 9YG-1.0 and a standard small hay baler regarding bale density?

A7. The 9YG-1.0 uses 16 heavy-duty steel rollers to compress the crop, achieving densities up to 200 kg/m³. Standard belt balers or simpler hay balers often achieve lower densities, which is less ideal for fermentation in silage production.

Q8. How many bales per hour can I realistically expect from this machine in normal conditions?

A8. In typical field conditions with an experienced operator, you can expect between 40 to 80 bales per hour. This varies depending on the crop volume (swath thickness), ground speed, and the wrapping settings used.

Q9. Is it possible to customize the hitch height for my specific tractor model if I order as a supplier?

A9. Yes, we offer OEM customization services. If you are a distributor or supplier ordering in volume, we can adjust the drawbar geometry, hydraulic couplers, and even the paint scheme to match your brand identity.

Q10. Does the machine come with a warranty and installation manual in English or Korean?

A10. Yes, the 9YG-1.0 comes with a 12-month warranty on main structural components. We provide a comprehensive operation and maintenance manual in English, and we can provide video tutorials to assist with setup.

Editor: PXY