Descrição

1. Technical Specifications: Precision Engineering for the Field

| Parameter / Item | Unit | Specification / Value |

|---|---|---|

| Model Name | / | 9LZ-6.0 Disc-type Hay Rake |

| Structure Type | / | Disc-type |

| Hitch Method | / | Trailed |

| Model Number | / | 9LZ-6.0 |

| Matched Power | kW | ≥25.73 (35-75 HP) |

| Dimensions (Working) | mm | 7600 × 6800 × 1500 |

| Machine Weight | kg | 1200 |

| Working Width | m | 6 |

| Working Speed | km/h | 7 ~ 10 |

| Transport Speed | km/h | ≤18 |

| Number of Finger Wheels | pcs | 12 |

| Number of Tines | pcs | 720 (12 wheels × 60 tines/wheel) |

| Operator Number | / | 1 |

| Windrow Width | m | 0.8 – 1.2 |

| Missed Raking Rate | % | ≤ 2% |

| Productivity | hm²/h | 4.2 ~ 6 |

Ancinho de feno tipo disco EP-9LZD-9.0

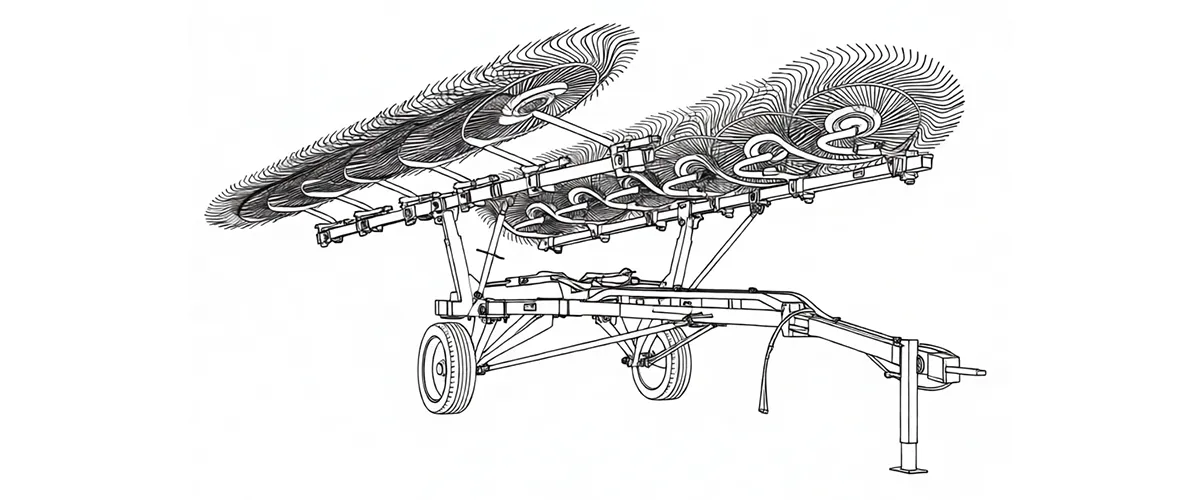

2. Product Overview: 9LZ-6.0 Disc-type Hay Rake for High-Efficiency Harvesting

In the evolving landscape of modern agriculture, particularly within the intensive farming sectors of East Asia such as South Korea, the efficiency of forage harvesting is paramount. The 9LZ-6.0 Disc-type Hay Rake represents the pinnacle of trailing rake technology, specifically engineered to meet the rigorous demands of large-scale straw and hay collection. Unlike smaller models, this machine boasts a substantial 6.0-meter working width, designed to significantly reduce the number of passes required in the field, thereby conserving fuel and minimizing soil compaction. This implement is not merely a tool but a comprehensive solution for managing rice straw, wheat stalks, and alfalfa. It is towed by a tractor with a power rating of greater than 25.73 kW (35 HP), making it highly compatible with the mid-sized tractors commonly found in Korean and Chinese agricultural operations. The rake excels in turning cutting and drying forage into neat, aerated windrows, which is critical for preventing mold growth in humid climates. Its hydraulic control system allows for the precise lifting of the finger discs, ensuring that operators can transition between transport and working modes seamlessly without leaving the cab. This focus on operator comfort and operational speed positions the 9LZ-6.0 as a market leader in the disc type hay rake for sale category.

The structural integrity of the 9LZ-6.0 is built upon a philosophy of durability and low maintenance. The frame utilizes high-grade steel to withstand the torsional stresses encountered during turns and over uneven terrain. The 12 independent finger plates are the heart of this machine; they are designed to float over ground contours, ensuring that crops are collected cleanly while stones and soil are left behind. This “clean rake” capability is essential for dairy farmers who require high-purity feed to maintain milk quality.

3. Working Principle, Materials, and Application Scenarios

Working Principle: The 9LZ-6.0 wheel hay rake operates on a ground-driven principle, which significantly reduces the power take-off (PTO) requirement from the tractor. As the machine is towed forward, the contact between the spring-steel tines and the ground (or the crop) causes the finger wheels to rotate. The angled arrangement of the 12 overlapping discs moves the crop from one wheel to the next, progressively rolling it into a fluffy, uniform windrow. This “axial flow” movement ensures that the hay is treated gently, preserving the nutrient-rich leaves of crops like alfalfa. The hydraulic system is integrated to lift the rake arms for transport or to cross non-crop areas, providing ease of operation directly from the driver’s seat. The absence of complex gearboxes or PTO shafts reduces the risk of mechanical failure and simplifies maintenance, making disc type hay rake parts easy to replace and source.

Materials & Metallurgy: Durability is non-negotiable in agricultural machinery. The main frame of the 9LZ-6.0 is constructed from Q345B high-strength structural steel, welded using robotic precision to ensure consistency and load-bearing capacity. The most critical components, the harvesting tines (spring fingers), are manufactured from 60Si2Mn spring steel. This material undergoes a specialized heat treatment process (quenching and tempering) to achieve a hardness of HRC 45-50. This ensures that the tines possess high elasticity to flick over rocks without breaking, yet enough rigidity to move heavy, wet silage. The hubs utilize sealed bearings to prevent dust and moisture ingress, extending the service life even in the muddy conditions often found in paddy fields.

Application Scenarios:

1. Rice Straw Collection in South Korea: After the combine harvester passes, rice straw is often left flat and damp. The 9LZ-6.0 effectively turns this straw to dry it out and windrows it for round balers. Its wide 6m width matches the efficiency needs of Korean agricultural cooperatives.

2. Alfalfa & Clover Harvesting: In dairy farming regions, preserving leaf integrity is key. The gentle action of the finger wheels minimizes leaf shatter, ensuring high-protein feed for livestock.

3. Corn Stalk Raking: For bio-energy or bedding, corn stalks are tough and heavy. The robust chassis of the 9LZ-6.0 handles this high-volume residue without clogging.

4. Land Reclamation: It can also be used to clear cut weeds and brush in pasture management applications.

4. Global Standards and Local Regulations (Focus on South Korea)

Operating agricultural machinery requires adherence to safety and environmental standards. The 9LZ-6.0 is manufactured in compliance with ISO 4254-1 (Agricultural machinery – Safety – General requirements). For our clients in South Korea, we pay special attention to the regulations set forth by the Korea Agricultural Machinery Industry Cooperative (KAMICO) and the safety inspection standards mandated by the Korean government.

South Korea Specific Regulations: In South Korea, agricultural machinery traveling on public roads (transport mode) must adhere to width restrictions and lighting requirements. The 9LZ-6.0 features a hydraulic folding mechanism that reduces its width significantly for transport, ensuring compliance with local road safety laws. Additionally, under the “Agricultural Mechanization Promotion Act,” machinery must meet durability and performance standards to qualify for government subsidies or loans (such as those from NACF – NongHyup). Our manufacturing process includes rigorous quality control (ISO 9001 certified) to ensure our equipment meets the criteria for durability performance tests often required for imported machinery in Korea. We also ensure that all hydraulic hoses and couplings meet international SAE standards, which are fully compatible with Korean service standards.

5. Market Trend Analysis: The Shift to Disc Rakes

The global market for hay and forage machinery is witnessing a distinct shift. Traditionally, bar rakes or rotary rakes were common, but the wheel hay rake (disc type) is gaining massive popularity, especially in the used hay rake for sale and new equipment markets. Why? The answer lies in simplicity and speed.

1. High-Speed Operation: Disc rakes like the 9LZ-6.0 can operate at speeds of 10-15 km/h (depending on field conditions), which is significantly faster than rotary rakes. In regions with unpredictable weather, speed is crucial to get the crop in before the rain.

2. Low Maintenance Costs: With no gearboxes to fail and fewer moving parts driven by PTO, the cost of ownership is lower. This is a major trend in 2024-2025 as farmers look to reduce operational overheads.

3. Biomass Energy: In Korea and China, the collection of corn stover and rice straw for biomass power generation is a booming industry. The 9LZ-6.0 is perfectly suited for this coarse, heavy material, driving demand in the renewable energy sector.

4. Clean Forage: As consumer demand for high-quality dairy and beef increases, so does the requirement for ash-free forage. The ground-following ability of independent discs ensures soil contamination is minimized.

6. Customer Success Story

Client 1 Profile: South KoreaCustomer Reviews:“As a large agricultural cooperative in Jeollanam-do, we use the 9LZ-6.0 Disc-type Hay Rake on our rice straw fields. The 6-meter working width reduces our field passes significantly, improving fuel efficiency and preventing soil compaction. We are particularly impressed by how the rake forms fluffy windrows, speeding up the drying process and ensuring high-quality straw for our livestock.”

Client 2 Profile: JapanCustomer Reviews:“We’ve been using the 9LZ-6.0 on our Hokkaido dairy farm for over a year. The rake does an excellent job of preserving alfalfa leaf integrity, which is crucial for the protein content in our feed. The hydraulic lift system is smooth and makes transitioning between transport and working modes effortless. The rake’s simplicity and speed are key for our operation during the busy hay season.”

Client 3 Profile: United StatesCustomer Reviews:“On our large New Jersey farm, the 9LZ-6.0 has become an indispensable part of our forage management. Its ground-driven mechanism means low maintenance, and it easily handles the high volumes of alfalfa we harvest. The rake’s ability to create clean windrows without soil contamination is particularly valuable, especially when baling for high-end dairy markets.”

7. The 9YG-1.25A Round Baler after-sales guarantee and support system.

1. Spare parts repair and replacement.

2. Every product comes with a free user manual.

3. After-sales service and warranty/maintenance.

4. Products delivered globally.

5. Professional language teams communicate to understand your needs.

6. Product training.

7. Every year during the grass-cutting season, we conduct follow-ups and market surveys for every herder who has purchased and used our products, and provide technical training for first-time users.

8. Related components.

For those searching for “replacement components hay baler,” our solution provides the precision and reliability needed for sustainable farming.

We also offer spare parts, including PTO Shaft & Tractor Gearbox, Drive Chain & Sprocket, Sheave & Pulley, Pickup Shaft Bearings & Shaft Collar, Hay Picker Shaft & Hay Picker Stand, Skids & Abrasion Plates, Teeth & Hay Picker Springs.

We’ll send you a detailed PDF of available replacement parts.

9. Frequently Asked Questions (FAQ)

Q1. Hi, I am looking for a disc-type hay rake for sale in South Korea. Can this 9LZ-6.0 be shipped to Incheon port?

A1. Absolutely! We have extensive experience exporting to East Asia. We can ship the 9LZ-6.0 in a container (CKD or semi-assembled) directly to Incheon or Busan port. We handle the packaging to ensure it arrives in perfect condition.

Q2. What is the main difference between the 9LZ-6.0 and the 9LZY-9.0 models I see in your catalog?

A2. Great question. The 9LZ-6.0 has a working width of 6 meters with 12 finger discs, requiring about 35 HP. The 9LZY-9.0 is a larger machine with a 9-meter width and 15 discs, requiring 50-55 HP. The 9LZ-6.0 is often better suited for mid-sized fields common in Korea.

Q3. I have a 45HP Kubota tractor. Is this powerful enough for the 9LZ-6.0 hay rake?

A3. Yes, perfectly compatible. The 9LZ-6.0 requires a minimum of 25.73 kW (approx. 35 HP). Your 45HP Kubota will handle it easily, providing ample hydraulic power for the lift system and traction for towing.

Q4. Can you tell me the disc type hay rake price including shipping?

A4. The price varies based on raw material costs and shipping rates. To give you an accurate quote (CIF or FOB), please click the “Get a Quote” button and leave your specific location and quantity. We offer competitive factory-direct pricing.

Q5. How do I maintain this rake? Are disc type hay rake parts easy to find?

A5. Maintenance is very simple: grease the wheel hubs regularly and check hydraulic hoses. Since we use standard agricultural specifications, parts like bearings and tines are widely available. We also supply a full spare parts kit with our shipments.

Q6. Does this rake work well on wet silage or just dry hay?

A6. It excels in both. The 60Si2Mn spring steel tines are stiff enough to move heavy, wet green forage (silage) effectively without bending, making it a versatile tool for early-season cuts.

Q7. How does the folding mechanism work for transport on narrow roads?

A7. The 9LZ-6.0 utilizes a hydraulic cylinder system. You simply operate a lever in your tractor cab, and the rake arms fold upwards and inwards, reducing the width significantly for safe road transport.

Q8. I see many types of hay rakes; why should I choose a wheel hay rake over a rotary one?

A8. Wheel rakes are generally faster, have fewer mechanical parts (no PTO shaft or gearboxes to break), and follow ground contours better. This makes them more cost-effective and reliable for large acreage.

Q9. What warranty do you offer on the 9LZ-6.0?

A9. We offer a standard 12-month warranty on the main frame and hydraulic components. We stand by our quality and will provide free replacement parts for any manufacturing defects during this period.

Q10. Can I customize the color to match my New Holland tractor?

A10. Yes, as an OEM manufacturer, we can paint the machine in specific colors, such as New Holland Blue, if you order a sufficient quantity. Contact us to discuss customization options.

Note: Technical parameters provided are based on the latest factory specifications for the 9LZ-6.0 model. Always refer to the specific technical drawing and manual for the exact dimensions and operational limits before purchase. Specifications may vary slightly due to continuous product improvement.

Editor: PXY