Описание

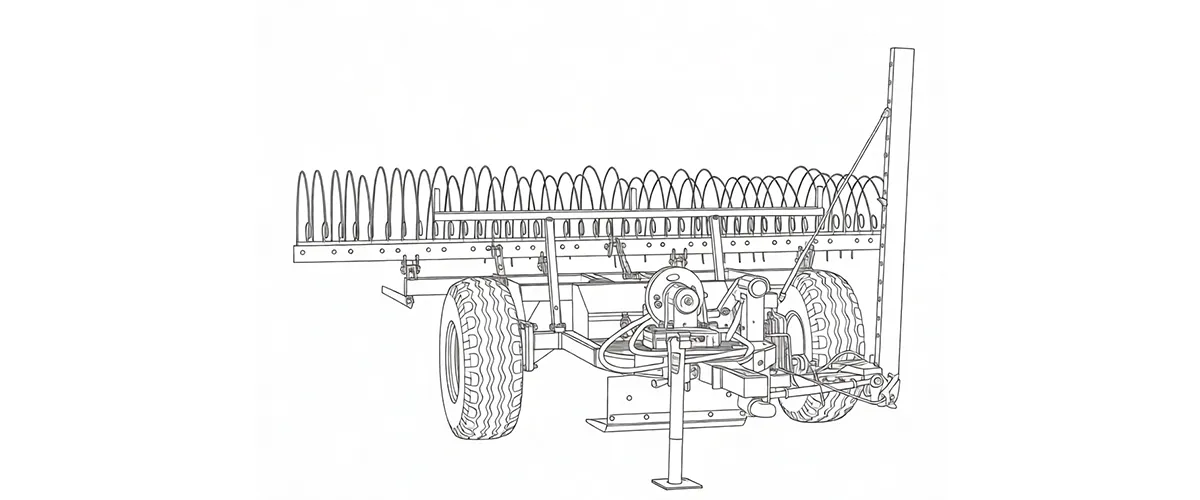

1. Technical Specifications: 9GL-2.5/2.9 Trailed Mower/Rake

| Item / Parameter | Единица | Specification / Value |

|---|---|---|

| Название модели | / | 9GL-2.5/2.9 Towed Mower |

| Hitch Method | / | Towed |

| Cutter Structure | / | Reciprocating Type |

| Cutting Width | м | 2.5 |

| Working Width | м | 2.9 |

| Working Speed Range | км/ч | 6 ~ 7 |

| Производительность | hm²/h | Mow: 1.2-1.44; Rake: 1.5-1.8 |

| Average Stubble Height | мм | 60-70 |

| Согласованная мощность | кВт | 25 ~ 55 |

| Tractor Output Shaft Speed | об/мин | 540 |

| Вес машины | кг | 920 |

| Number of Cutter Blades | Pieces | 42 |

| Cutting Distance | мм | 71 |

| External Dimensions | мм | 3100×2920×2900 |

| Working Dimensions | мм | 3100×5000×950 |

2. 9GL-2.5/2.9 Trailed Mower/Rake: The Ultimate 2-in-1 Solution for Efficient Forage Harvesting in South Korea

3. Advanced Engineering: How the Cut-and-Rake System Works

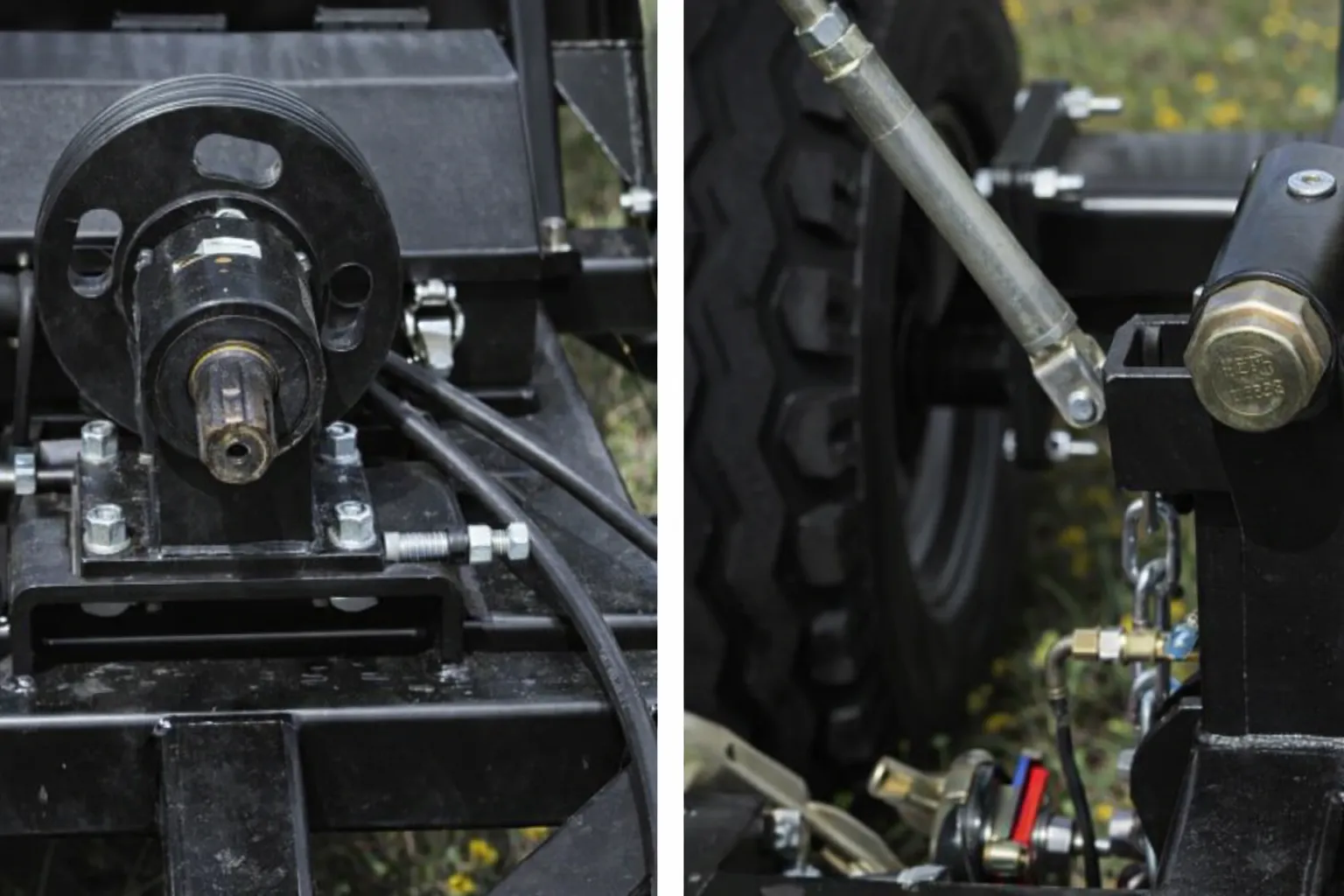

The operational brilliance of the 9GL-2.5/2.9 lies in its synchronized dual-action mechanism. The primary cutting system employs a heavy-duty reciprocating knife bar, similar to high-end sickle bar mowers, which delivers a clean, scissor-like cut. This method is superior to rotary impact cutting for retaining leaf integrity, which is crucial for high-protein feed.As the crop is severed, the integrated raking mechanism, equipped with 42 specialized steel tines, immediately engages the material. These tines are spaced precisely at 71mm intervals to ensure thorough collection without dragging soil or debris into the windrow. The entire apparatus is supported by pneumatic rubber tires, making it a true tow-behind mower system that reduces drag and wear on the tractor. The power transmission is handled via a standard 540 r/min PTO shaft, which drives both the eccentric bushing for the cutter bar and the belt/chain drive for the rake. Crucially, the hydraulic system allows for independent or simultaneous lifting of the mowing and raking units, providing the operator with flexibility when navigating headlands or transport scenarios. This integration ensures that the “acreage tow behind rough cut mower” concept is elevated to a precision agricultural process.

4. Forage Harvesting Trends: The Shift Towards Multi-Functionality in Korea

The agricultural machinery market in South Korea is currently undergoing a significant transformation driven by an aging farming population and a government-led initiative towards “Smart and Efficient Farming.” Trend analysis indicates a sharp decline in the demand for single-function implements in favor of multi-functional combinations like the 9GL-2.5/2.9. Farmers can no longer afford the time or fuel to drive a tractor over the same field twice—once to mow and once to rake. Furthermore, the Korean market is increasingly sensitive to forage quality; the faster hay can be cut and windrowed for baling, the less nutrient loss occurs due to sun bleaching or unexpected rainfall. This machine addresses the “Golden Time” of harvest by halving the field time. Globally, we are seeing a similar trend where the towed double-blade lawn mower concepts are being scaled up for agriculture. The 9GL series capitalizes on this by offering a solution that is compatible with mid-range tractors (35-75hp), which constitute the bulk of the existing tractor fleet in Korea, avoiding the need for farmers to invest in heavier, more expensive power units.

5. Material Composition and Heavy-Duty Construction

Durability is non-negotiable when dealing with the variable vegetation found in pastures, from thick alfalfa to tough native grasses. The 9GL-2.5/2.9 is constructed using high-grade structural steel Q345 for the main chassis, providing the necessary rigidity to prevent twisting during operation on uneven ground. The 34 moving blades are forged from specialized 65Mn spring steel, treated with a proprietary heat-induction process to achieve a hardness of HRC 52-56. This ensures the blades maintain a razor-sharp edge significantly longer than standard carbon steel blades, reducing maintenance downtime. The 42-raking tines are manufactured from high-elasticity alloy steel wire, allowing them to flex over rocks and undulations without snapping, yet remaining stiff enough to move heavy, wet green forage. The machine weighs approximately 920kg, a mass that reflects its solid build quality rather than unnecessary bulk. The exterior is finished with an electrostatic powder coating process that provides superior resistance to corrosion, a critical feature for machinery exposed to the humid Korean monsoon season and morning dew common in forage fields.

6. Compliance with Korean and International Agricultural Safety Standards

Exporting machinery to South Korea requires strict adherence to local safety and performance regulations. The 9GL-2.5/2.9 is manufactured in compliance with the rigid standards set forth by the Korea Agricultural Machinery Industry Cooperative (KAMICO) and aligns with the safety inspection protocols of the Rural Development Administration (RDA). Specifically, the machine includes mandatory safety guards over all moving drive chains and PTO shafts to prevent entanglement, a critical requirement under Korea’s Occupational Safety and Health regulations for farming. Furthermore, the hydraulic system features check valves to prevent the accidental lowering of the cutter bar during transport, complying with road safety laws for towed agricultural implements.

On an international level, the manufacturing process follows ISO 9001 quality management systems. For the rake tines and cutter bar, we adhere to standards that limit soil contamination in forage, ensuring the final silage or hay meets the hygiene standards required by the Korean dairy industry. We provide full documentation to assist Korean importers and farmers in applying for government subsidies often available for purchasing high-efficiency agricultural machinery.

7. Equipment Compatibility and Component Comparison

| System / Part | EVER-POWER Specification | Market Compatibility / Equivalent |

|---|---|---|

| Tractor Power Interface | Standard 6-Spline 1-3/8″ PTO | Compatible with LS, TYM, Kubota, Daedong (35-75HP range) |

| Hydraulic Connection | Quick Coupler ISO 7241-1 A | Universal fit for standard Korean agricultural hydraulic outputs |

| Blade Type | Serrated Sickle Section | Interchangeable with major brands like Busatis or Schumacher (check bolt hole) |

| Tires | Agricultural Ribbed Tires | Standard agricultural rims, tires easily sourced in local markets |

8. Система послепродажного обслуживания и поддержки пресс-подборщика 9YG-1.25A.

1. Ремонт и замена запасных частей.

2. К каждому изделию прилагается бесплатное руководство пользователя.

3. Послепродажное обслуживание и гарантийный ремонт/техническое обслуживание.

4. Продукция поставляется по всему миру.

5. Профессиональные языковые команды общаются, чтобы понять ваши потребности.

6. Обучение по продукту.

7. Каждый год во время сезона скашивания травы мы проводим последующие проверки и исследования рынка для каждого скотовода, который приобрел и использовал нашу продукцию, а также предоставляем техническое обучение для тех, кто использует ее впервые.

9. Сопутствующие компоненты.

For those searching for “Shaft Collar for round balers” or “replacement Shaft Collar for hay baler,” our solution provides the precision and reliability needed for sustainable farming.

Мы также предлагаем запасные части, в том числе Вал отбора мощности и редуктор трактора, приводная цепь и звездочка, шкив и ролик, подшипники вала подборщика и втулка вала, вал и подставка для сенокосилки, салазки и износостойкие пластины, зубья и пружины сенокосилки.

Связаться с нами, и мы вышлем вам подробную информацию. PDF доступных запасных частей.

10. Frequently Asked Questions (FAQ)

Q1. Is the 9GL-2.5/2.9 mower/rake compatible with older 35HP tractors commonly found in rural Korea?

A1. Yes, absolutely. We specifically designed the 9GL-2.5/2.9 to be power-efficient. It operates smoothly with a power range starting at 25kW (approx. 35HP). As long as your older tractor has a standard 540 RPM PTO shaft and a rear hydraulic outlet for the lift cylinder, it will function perfectly, making it an excellent upgrade for older fleets.

Q2. How does the combined mowing and raking function affect the drying time of the hay compared to doing it separately?

A2. It significantly accelerates drying. By cutting and immediately raking the forage into a fluffy windrow, you increase airflow through the crop right from the moment of cutting. This eliminates the time the crop sits flat on the damp ground, reducing the risk of mold and preserving the nutritional value of the feed.

Q3. What is the estimated shipping cost and lead time for ordering this unit to Incheon port?

A3. Shipping costs vary based on current ocean freight rates and order volume. However, the transport dimensions (3100x2920x2900 mm) allow us to optimize container space. Typically, production takes 15-20 days, and shipping to Incheon takes approximately 3-7 days. Please use the “Get a Quote” button for a precise CIF price.

Q4. Can this machine handle thick, wet rice straw residue often found in Korean fields after harvest?

A4. While primarily designed for pasture grass, the reciprocating knife is powerful enough to cut thick stems. The raking tines are robust; however, for heavy wet rice straw, we recommend operating at a slightly slower speed (approx. 5 km/h) to ensure the rake doesn’t clog and to form a clean windrow.

Q5. Where can I buy replacement parts like the sickle sections or raking tines if they break?

A5. We provide a comprehensive spare parts kit with every machine purchase. Additionally, we use standard-sized sickle sections and tines that are compatible with many universal agricultural parts available in local Korean machinery shops. We can also express ship parts directly from our factory.

Q6. Is the 9GL-2.5/2.9 suitable for uneven or hilly terrain common in mountainous Korean provinces?

A6. This model is a “Trailed” unit with pneumatic tires, which offers good stability. It is designed for flat to slightly sloping pastures. For extremely steep mountain slopes, we recommend caution, but for rolling hills, the flexible hitch and tire suspension handle the terrain well without scalping the ground.

Q7. How difficult is the assembly process if I import this machine semi-knocked down (SKD)?

A7. Assembly is straightforward. The main chassis comes pre-assembled. You will mostly need to attach the raking arms, wheels, and drawbar. We provide a detailed video guide and an English/Korean instruction manual. Two people can typically complete the assembly in 2-3 hours with standard tools.

Q8. Does the machine come with a warranty for the hydraulic cylinder and gearbox components?

A8. Yes, we offer a 12-month warranty on core components including the gearbox, hydraulic cylinder, and main frame. Wear parts like blades and tines are excluded, but if there is any manufacturing defect, we will replace the parts free of charge immediately.

Q9. Can I adjust the width of the windrow produced by the raking mechanism?

A9. The raking width is fixed at 2.9 meters due to the mechanical design, but the resulting windrow density can be managed by adjusting your driving speed. A faster speed will create a thinner windrow, while a slower speed allows for a denser pile, depending on your baler’s requirements.

Q10. What is the price difference between this combined unit and buying a separate mower and rake?

A10. The 9GL-2.5/2.9 is a highly cost-effective option. Generally, purchasing this combined unit costs about 30-40% less than buying a comparable standalone reciprocating mower and a separate rotary rake. Plus, you save on the fuel and labor costs of running the tractor twice.

Редактор: PXY