Beskrivning

1. Tekniska specifikationer och prestandadata

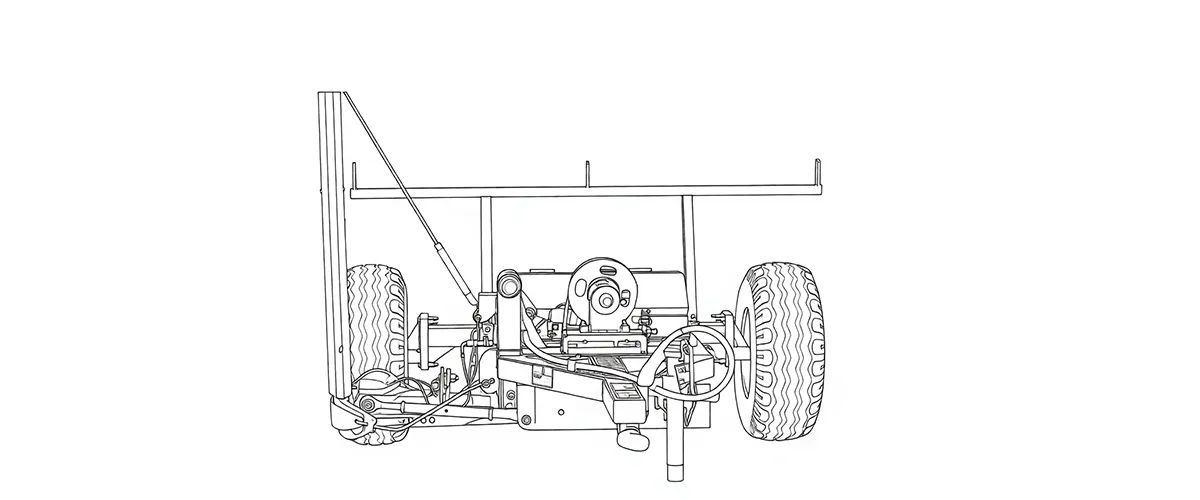

To provide a clear engineering perspective, the following table details the precise specifications of the 9GD-2.5. These parameters are essential for compatibility checks with your existing tractor fleet.

| Parameter / Objekt | Enhet | Specifikation / Värde |

|---|---|---|

| Modellnamn | / | 9GD-2.5 Trailed Single Blade Mower |

| Hitch-metoden | / | Trailed (Side Traction) |

| Cutter Structure | / | Reciprocating Type |

| Cutting Width | Meters (m) | 2.5 |

| Matchad kraft | KW (HP) | 15-35 KW (20-50 HP) |

| Arbetshastighet | km/h | 6 – 10 |

| Number of Moving Blades | Pieces | 34 |

| Dimensions (L×W×H) | mm | 2000 × 4300 × 950 |

| PTO Speed | varv/min | 540 |

| Stubble Height | mm | 50 – 70 |

| Produktivitet | hm²/h | 2.0 – 3.0 |

| Strukturell vikt | kg | 490 |

EP-9GD 2.5 Enkelbladsklippare (uppgraderad version)

2. Five Key Facts

2.1. Efficient and Low Maintenance Design: The 9GD-2.5 Trailed Single Blade Mower is equipped with a reciprocating cutter, providing clean cuts that preserve the nutritional quality of forage crops like alfalfa and ryegrass. Its low power requirement (15-35 kW) ensures fuel efficiency and suitability for medium-sized tractors.

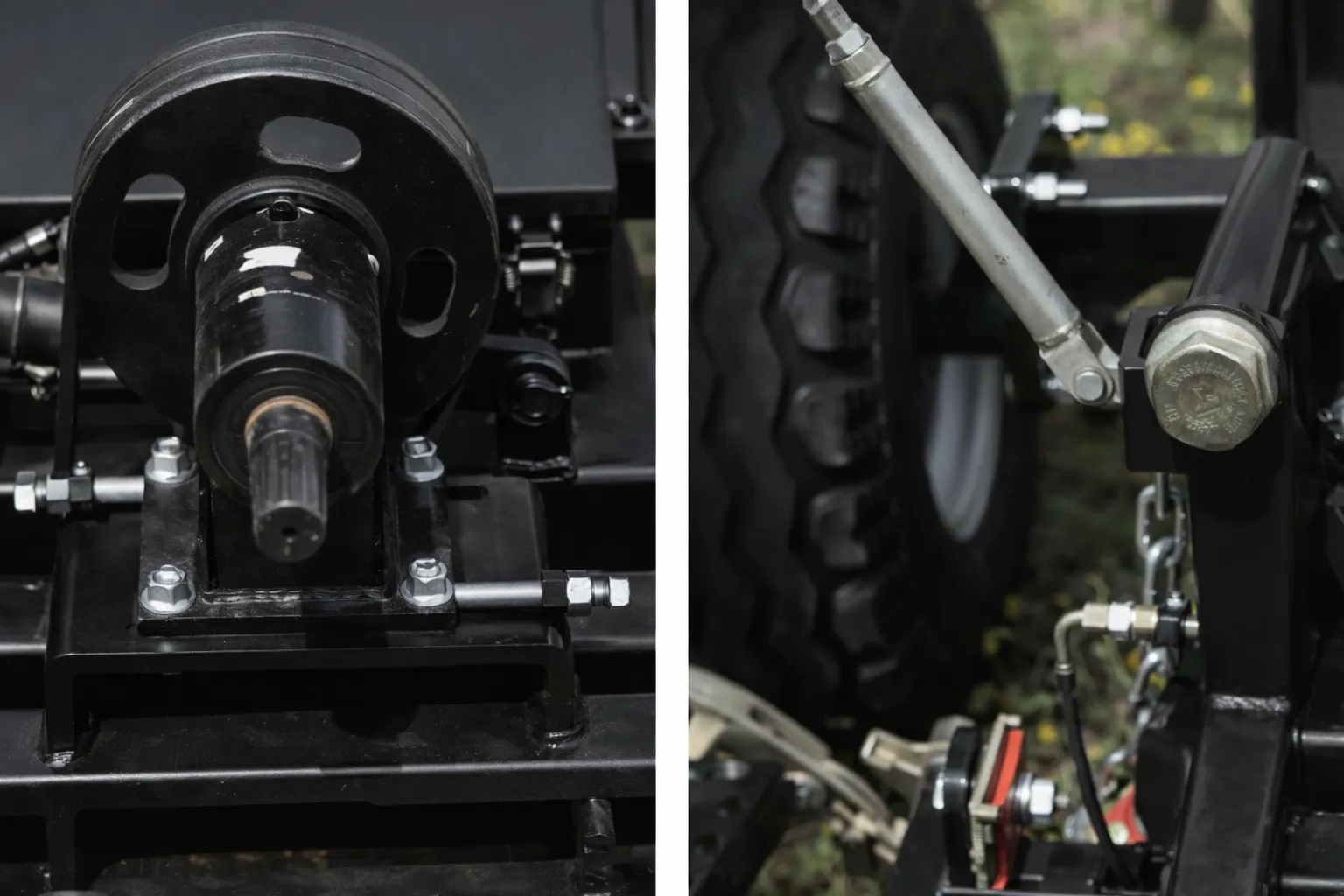

2.2. Advanced Hydraulic System: This mower features an advanced hydraulic lifting mechanism for easy operation, allowing farmers to switch between transport and working modes or avoid obstacles without leaving the tractor. This functionality reduces manual labor and enhances safety.

2.3. Durable Construction for Tough Conditions: The mower is built with high-strength materials like heat-treated alloy steel for the blades and reinforced Q345B structural steel for the frame. This robust design ensures longevity and reliable performance, even in challenging field conditions.

2.4. Versatile and Efficient: With a cutting width of 2.5 meters and a productivity rate of 2.0-3.0 hectares per hour, the 9GD-2.5 is ideal for medium-sized farms. Its reciprocating action and floating system allow it to adapt to varying terrains, minimizing soil compaction and promoting faster plant regrowth.

2.5. Regulatory Compliance: The 9GD-2.5 mower complies with international agricultural machinery safety standards, including ISO 4254-1 and South Korean safety regulations. This ensures safe operation and meets local certification requirements for agricultural machinery in markets like South Korea and Europe.

3. Comprehensive Analysis and Technical Overview of the 9GD-2.5 Trailed Single Blade Reciprocating Mower for Professional Forage Harvesting

4. Tekniska principer, materialmetallurgi och tillämpningsscenarier

The fundamental working principle of the 9GD-2.5 relies on a reciprocating crank-link mechanism that converts the rotational energy from the tractor’s PTO (Power Take-Off) into the linear oscillating motion of the cutter bar. This is distinct from rotary mowers that rely on high-impact speed to shatter plant stems. The reciprocating motion shears the plant stem against a stationary ledger plate, mimicking the action of scissors. This requires significantly less horsepower per meter of cut compared to rotary alternatives, explaining why a 2.5-meter width can be effectively driven by a mere 20HP tractor. Material selection is paramount in this assembly; the blades are forged from heat-treated high-carbon alloy steel to resist abrasive wear from silica-rich grasses like rice straw or mature ryegrass. The main frame is constructed from reinforced structural steel to withstand the torsional stresses induced during trailing operation over uneven ground. The hydraulic system components are sourced to withstand high-pressure cycles, ensuring the lifting mechanism remains responsive after thousands of actuation cycles. This metallurgical robustness ensures that when you see a trailed single blade lawn mower for sale under our brand, it represents industrial-grade durability.

regarding application scenarios, the 9GD-2.5 is specifically calibrated for the harvesting of soft-stemmed crops such as alfalfa, clover, ryegrass, and native meadow grasses. Its gentle cutting action significantly reduces leaf loss—a critical factor in preserving the protein content of alfalfa hay. In the context of the South Korean agricultural sector, this machine is ideally suited for the standardized rice paddy banks (when dry) and designated forage production zones where maintaining feed quality is prioritized over sheer destruction speed. However, it is crucial to adhere to the operational limitations: the machine is not designed for clearing forestry undergrowth, rocky wastelands, or wetland marshes where the reciprocating teeth could become jammed or damaged. By focusing on appropriate agronomic applications, operators can achieve a productivity rate of 2.0 to 3.0 hectares per hour. This efficiency makes it a top contender for cooperatives and medium-scale livestock farms looking to upgrade their forage harvesting capabilities. The trailed design also minimizes the weight load on the tractor’s rear axle compared to mounted units, preserving soil structure by reducing compaction—a vital consideration for sustainable farming practices advocated by global environmental agencies.

5. Global Regulatory Compliance and Safety Standards (Korea & International)

In the manufacturing and export of agricultural machinery, strict adherence to international safety and quality standards is non-negotiable for ensuring operator safety and market entry. The 9GD-2.5 Trailed Single Blade Mower is manufactured in strict compliance with the GB/T 10940-2008 standard for “Reciprocating Mowers,” which dictates rigorous testing protocols for cutting performance, structural integrity, and safety guarding. For our partners and clients in South Korea, we are acutely aware of the requirements outlined in the Agricultural Mechanization Promotion Act and the specific safety criteria set by the Korea Agricultural Technology Promotion Agency (KOAT). Although GB standards are our manufacturing baseline, our design philosophy aligns with ISO 4254-1 (Agricultural machinery – Safety – Part 1: General requirements), ensuring that PTO shafts are fully shielded to prevent entanglement hazards—a critical compliance point for entering the Korean and European markets. We ensure that all hydraulic lines meet burst pressure safety factors and that safety decals are compliant with ISO 11684.

Furthermore, when exporting to regions with stringent environmental and safety regulations, such as the European Union or North America, we ensure our documentation and product safety features align with the Machinery Directive 2006/42/EC and relevant ANSI/ASABE standards, respectively. For the South Korean market, specifically regarding the “Safety Inspection of Agricultural Machinery,” our equipment is designed to pass inspections related to moving parts protection, lighting for road transport (if applicable), and stability during towing. We understand that local laws in Gangwon-do or Jeollanam-do might have specific municipal guidelines regarding road travel for trailed implements, and we provide comprehensive dimensions and weight data to assist our customers in maintaining full legal compliance.

6. Component Compatibility and Market Comparison

Understanding where the 9GD-2.5 fits within the broader market is crucial for informed procurement. The table below compares our specific model against generic market standards and highlights component compatibility.

| Särdrag | EVER-POWER 9GD-2.5 | Generic Rotary Mower | Competitor Reciprocating |

|---|---|---|---|

| Power Efficiency | High (Requires only 20HP) | Low (Usually requires 40HP+) | Medium (Often heavier drag) |

| Cut Quality | Clean Shear (Fast Regrowth) | Impact/Tear (Slower Regrowth) | Variabel |

| Tractor Hitch | Universal Trailed Pin | 3-Point Linkage | 3-Point Linkage |

| Blade Compatibility | Standard Reciprocating Sections | Specific Rotary Blades | Proprietary Only |

| Terrain Adaptation | Excellent (Floating Trailed) | Fair (Rigid Mount) | Good |

7. Market Trends: The Shift Towards Efficient and Sustainable Forage Harvesting

The global agricultural machinery market is witnessing a decisive shift away from power-hungry, heavy implements towards lighter, more energy-efficient solutions. This trend is particularly evident in South Korea and East Asia, where farm sizes are consolidating, and operational efficiency is paramount. The demand for the trailed single-blade lawn mowers and forage harvesters is driven by the rising costs of fuel and the need for sustainable farming practices. Rotary mowers, while fast, often consume excessive fuel and can damage the crop’s root system through “scalping” on uneven terrain. In contrast, the 9GD-2.5 aligns perfectly with the “Low-Carbon Agriculture” initiatives being promoted globally. By requiring lower horsepower, it reduces the carbon footprint per hectare harvested.

Furthermore, there is a growing trend in the “Used” equipment market, where buyers actively search for a used trailed single-blade lawn mower. This indicates a robust secondary market value for these machines, proving their durability and long-term asset value. However, the trend also highlights a gap in the market for affordable new machinery that bridges the price point between expensive European imports and risky second-hand units.

EVER-POWER addresses this by providing a brand-new, high-spec machine at a competitive price point, effectively disrupting the used equipment market by offering better value, warranty, and reliability. The trend also favors machines with simplified hydraulics and mechanical linkages, like the 9GD-2.5, which allow for easier on-farm repairs compared to complex electronic-controlled systems.

8. Factory Customization Capabilities and Quality Assurance

9. Customer Success Story

10. The 9YG-1.25A Round Baler after-sales guarantee and support system.

1. Reparation och utbyte av reservdelar.

2. Varje produkt levereras med en gratis användarmanual.

3. Eftermarknadsservice och garanti/underhåll.

4. Produkter levererade globalt.

5. Professionella språkteam kommunicerar för att förstå dina behov.

6. Produktutbildning.

7. Varje år under gräsklippningssäsongen genomför vi uppföljningar och marknadsundersökningar för varje herde som har köpt och använt våra produkter, och tillhandahåller teknisk utbildning för förstagångsanvändare.

11. Related components.

För dig som söker efter ”Axelkrage för rundbalpressar” eller ”ersättningsaxelkrage för höbalpress” erbjuder vår lösning den precision och tillförlitlighet som behövs för hållbart jordbruk.

Vi erbjuder även reservdelar, inklusive Kraftuttagsaxel och traktorväxellåda, drivkedja och kedjehjul, skiva och remskiva, uppsamlingsaxelns lager och axelkrage, höupptagningsaxel och höupptagningsstativ, medar och slitplattor, tänder och höupptagningsfjädrar.

Kontakta oss, och vi skickar dig en detaljerad PDF av tillgängliga reservdelar.

12. Frequently Asked Questions (FAQ)

Q1. What is the exact price quote for the 9GD-2.5 trailed single blade lawn mower delivered to Incheon port?

A1. The specific cost depends on the current raw material prices and shipping rates to South Korea. As a direct supplier, we offer competitive factory pricing. Please click the “Get a Quote” button to receive a detailed proforma invoice including FOB or CIF Incheon terms within 24 hours.

Q2. Can I use this mower with my older 25HP Kubota tractor for harvesting alfalfa?

A2. Yes, absolutely. The 9GD-2.5 is designed to operate efficiently with tractors in the 15-35KW (20-50 HP) range. A 25HP Kubota is an ideal match, providing sufficient PTO power for the reciprocating action while easily handling the trailing weight.

Q3. Where can I find replacement blades and parts for this trailed mower in South Korea?

A3. We supply a comprehensive spare parts kit with every machine. Additionally, we use standard specification blades that are often compatible with universal reciprocating mower parts. We can also ship urgent replacement parts directly to you via DHL/FedEx to ensure minimal downtime.

Q4. How does the 9GD-2.5 compare to a rotary mower for preserving forage nutritional quality?

A4. This reciprocating mower acts like scissors, providing a clean shear that keeps the plant stem intact. Rotary mowers tear the grass, which can cause moisture loss and slower regrowth. For high-quality nutritional forage like alfalfa, the 9GD-2.5 is the superior choice.

Q5. Is it safe to buy a used trailed single blade lawn mower instead of a new one?

A5. While a used trailed single blade lawn mower might seem cheaper initially, you risk inheriting worn-out crank mechanisms and hydraulic leaks. Our new 9GD-2.5 is priced competitively, often close to used market prices, but comes with a full warranty and zero wear, offering much better long-term value.

Q6. Which hydraulic oil should be used for the lifting cylinder in cold Korean winters?

A6. For colder climates like Korean winters, we recommend using a high-quality ISO VG 32 or VG 46 hydraulic oil. These viscosities ensure the lifting mechanism remains responsive even in low temperatures, preventing pump strain and seal damage.

Q7. How do I adjust the stubble height on the 9GD-2.5 for different crop types?

A7. The stubble height (50-70mm) is adjusted via the skid shoes and the angle of the cutter bar. The manual provided details the simple mechanical adjustments needed to raise or lower the cutting deck to suit crops ranging from dense ryegrass to lighter native grasses.

Q8. What are the shipping dimensions if I want to order a container load for my dealership?

A8. The working dimensions are 2000×4300×950 mm, but for shipping, we can package them more compactly. We can fit multiple units in a 20ft or 40ft container to optimize your freight costs. Contact us for a specific loading plan.

Q9. Does this machine comply with South Korean agricultural machinery safety regulations?

A9. Yes, the machine is designed with standard PTO shielding and hydraulic safety factors that meet international standards, including compatibility with requirements found in Korea. We can provide necessary technical documentation to assist with local certifications.

Q10. Can you customize the paint color to match my company’s branding for a bulk order?

A10. Certainly. As an OEM-capable factory, we can customize the paint color (e.g., John Deere Green, Kubota Orange, or your brand color) and apply your logo decals for bulk orders. This helps in maintaining your brand identity in the local market.

Redaktör: PXY