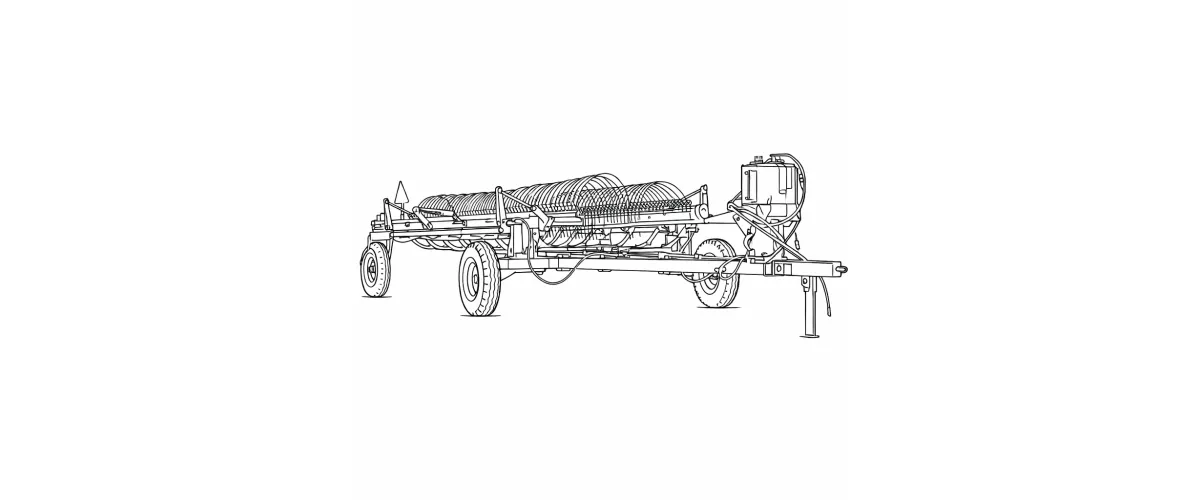

விளக்கம்

1. தொழில்நுட்ப விவரக்குறிப்புகள்: 9LH-12 கிடைமட்ட வைக்கோல் ரேக்

| அளவுரு / பொருள் | அலகு | தரவு விவரக்குறிப்பு |

|---|---|---|

| மாதிரி பெயர் | / | 9LH-12 கிடைமட்ட வைக்கோல் ரேக் |

| கட்டமைப்பு வகை | / | இயந்திரத்தால் வரையப்பட்ட கிடைமட்ட வகை |

| ஹிட்சிங் முறை | / | டிரெயில்டு / டிராபார் |

| பொருந்திய சக்தி | கிலோவாட் (ஹெச்பி) | 25 – 44 (35 – 60 ஹெச்பி) |

| ரேக்கிங் அகலம் | மீ | 12.0 |

| வேலை வேகம் | கிமீ/ம.நே. | 5 ~ 10 |

| தயாரிப்பு | hm²/ம | 6 ~ 12 (தோராயமாக 15-30 ஏக்கர்/மணி) |

| மொத்த ரேக் பற்கள் | பிசிக்கள் | 168 |

| தவறவிட்ட ரேக்கிங் விகிதம் | % | ≤ 3% ≤ 3% |

| கட்டமைப்பு எடை | கிலோ | 1510 |

| வேலை செய்யும் பரிமாணங்கள் (L×W×H) | மிமீ | 5500 × 12000 × 1350 |

| போக்குவரத்து பரிமாணங்கள் (L×W×H) | மிமீ | 9400 × 3400 × 1750 |

2. 9LH-12 கிடைமட்ட வைக்கோல் ரேக்: தென் கொரியாவில் பெரிய அளவிலான தீவன அறுவடையில் புரட்சியை ஏற்படுத்துதல்.

வைக்கோலை கயிறு கட்டி அல்லது மண் மாசுபடுத்திகளை அறிமுகப்படுத்தும் நிலையான சுழலும் அல்லது சக்கர ரேக்குகளைப் போலல்லாமல், 9LH-12 ஒரு சிறப்பு கிடைமட்ட பொறிமுறையைப் பயன்படுத்தி வெட்டப்பட்ட தீவனத்தை மெதுவாக துடைக்கிறது - அது அல்பால்ஃபா, திமோதி அல்லது பூர்வீக கொரிய புற்களாக இருந்தாலும் சரி - பயணத்தின் திசைக்கு செங்குத்தாக துல்லியமான, பஞ்சுபோன்ற விண்ட்ரோக்களாக. இந்த இயந்திரம் 12 மீட்டர் வேலை அகலத்தைக் கொண்டுள்ளது, இது உங்கள் டிராக்டருக்குத் தேவையான பாஸ்களின் எண்ணிக்கையை கணிசமாகக் குறைக்கிறது, இதன் மூலம் மண் சுருக்கம் மற்றும் எரிபொருள் பயன்பாட்டைக் குறைக்கிறது. நடுத்தர தூர டிராக்டர்களுடன் (35-60 ஹெச்பி) இயக்க வடிவமைக்கப்பட்ட இது, அதிக குதிரைத்திறன் கொண்ட பிரைம் மூவர்களில் முதலீடு செய்ய வேண்டிய அவசியமின்றி உயர் திறன் கொண்ட ரேக்கிங்கை அணுகக்கூடியதாக ஆக்குகிறது. மழைக்காலம் (ஜாங்மா) விரைவான உலர்த்தும் நேரங்களைக் கோரும் ஜியோல்லா அல்லது சுங்சியோங் போன்ற பகுதிகளில் செயல்பாடுகளை நிர்வகிக்கும் கொரிய விவசாயிகளுக்கு, நன்கு காற்றோட்டமான விண்ட்ரோக்களை உருவாக்கும் 9LH-12 இன் திறன் ஒரு கேம்-சேஞ்சராகும். இந்த வைக்கோல் ரேக், காற்றோட்டக் குழாய் வழியாக காற்றோட்டத்தை மேம்படுத்துவதன் மூலம், டிராக்டர் பயன்பாட்டிற்கான ஈரப்பதம் விரைவாகக் குறைவதை உறுதிசெய்கிறது, தீவனத்தின் ஊட்டச்சத்து மதிப்பைப் பாதுகாக்கிறது மற்றும் உயர்தர ஹன்வூ மாட்டிறைச்சி மற்றும் பால் உற்பத்திக்கு மிக முக்கியமான பூஞ்சை வளர்ச்சியைத் தடுக்கிறது.

3. செயல்பாட்டு இயக்கவியல், பொருள் பொறியியல் மற்றும் பயன்பாட்டு காட்சிகள்

9LH-12 இன் செயல்பாட்டு புத்திசாலித்தனம் அதன் தனித்துவமான கிடைமட்ட ரேக்கிங் செயல்பாட்டில் உள்ளது. இந்த இயந்திரம் ஒரு வலுவான சட்டத்தில் பொருத்தப்பட்ட 168 சிறப்பு எஃகு டைன்களின் வரிசையைப் பயன்படுத்துகிறது. டிராக்டர் அலகை இழுக்கும்போது, ஹைட்ராலிக் அமைப்பு ரேக்கிங் பொறிமுறையைக் குறைக்கிறது. இந்த டைன்கள் பயிரை மென்மையான துடைக்கும் இயக்கத்துடன் ஈடுபடுத்துகின்றன, பொருளை பக்கவாட்டாக நகர்த்தி டிராக்டரின் பாதைக்கு செங்குத்தாக அமைந்துள்ள ஒரு விண்ட்ரோவை உருவாக்குகின்றன. தீவனத்தில் புரதத்தின் முதன்மை ஆதாரமான இலை உடைப்பைக் குறைப்பதால், க்ளோவர் அல்லது அல்பால்ஃபா போன்ற நுட்பமான பயிர்களுக்கு ஆக்கிரமிப்பு சுழலும் செயல்களை விட இந்த முறை மிகவும் சிறந்தது. இந்த சட்டகம் Q345 கட்டமைப்பு எஃகிலிருந்து கட்டமைக்கப்பட்டுள்ளது, இது சீரற்ற மேய்ச்சல் நிலத்தில் 12 மீட்டர் கருவியை இழுக்கும் அழுத்தங்களைத் தாங்கும் அதிக இழுவிசை வலிமையை வழங்குகிறது. டைன்கள் வெப்ப-சிகிச்சையளிக்கப்பட்ட ஸ்பிரிங் ஸ்டீல் ஆகும், இது கனமான, ஈரமான பச்சை துண்டுகளை நகர்த்துவதற்கு போதுமான விறைப்புத்தன்மையை பராமரிக்கும் போது உடைப்பைத் தடுக்க சிறிய தடைகளுடன் தாக்கத்தின் போது வளைந்து கொடுக்கும் வகையில் வடிவமைக்கப்பட்டுள்ளது.

பயன்பாட்டு சூழ்நிலைகளைப் பொறுத்தவரை, 9LH-12 பெரிய, தட்டையானது முதல் மெதுவாக உருளும் இயற்கை மேய்ச்சல் நிலங்கள் மற்றும் பயிரிடப்பட்ட தீவன வயல்களுக்கு குறிப்பாக உகந்ததாக உள்ளது. கிடைமட்ட வைக்கோல் ரேக் வேகம் அவசியமான செயல்பாடுகளுக்கான தீர்வு. ஹைட்ராலிக் லிஃப்ட் அமைப்பு, டிராக்டர் கேபினிலிருந்து முழுமையாகக் கட்டுப்படுத்தப்படும் ஹெட்லேண்டுகளில் அல்லது பயிர் அல்லாத பகுதிகளைக் கடக்கும்போது டைன்களை சிரமமின்றி உயர்த்த ஆபரேட்டரை அனுமதிக்கிறது. ஹைட்ராலிக்ஸ் மற்றும் மெக்கானிக்ஸின் இந்த தடையற்ற ஒருங்கிணைப்பு, ஒரு ஒற்றை ஆபரேட்டர் முழு ரேக்கிங் செயல்முறையையும் நிர்வகிக்க முடியும் என்பதை உறுதி செய்கிறது, இது மணிக்கு 12 ஹெக்டேர் வரை உள்ளடக்கியது. இது திறந்தவெளிகளில் சிறந்து விளங்கினாலும், அதன் கணிசமான அகலம் காரணமாக, மலை மொட்டை மாடி விவசாயத்தில் பெரும்பாலும் காணப்படும் சிறிய, துண்டு துண்டான நிலங்களுக்கு இது குறைவாகவே பொருத்தமானது என்பதை ஆபரேட்டர்கள் கவனிக்க வேண்டும். இது தொழில்முறை, பரந்த ஏக்கர் தீவன மேலாண்மைக்கான ஒரு பிரத்யேக கருவியாகும், அடுத்தடுத்த பேலிங் செயல்பாடுகள் சீரான காற்றோட்டங்களுடன் அதிகபட்ச திறனில் தொடர முடியும் என்பதை உறுதி செய்கிறது.

4. போக்கு பகுப்பாய்வு: கிழக்கு ஆசியாவில் பரந்த பகுதிகளுக்கு மாறுதல்

தென் கொரியாவிலும், கிழக்கு ஆசியா முழுவதிலும் விவசாய இயந்திரத் துறை ஒரு தீர்க்கமான மாற்றத்திற்கு உட்பட்டுள்ளது, ஒருங்கிணைப்பு மற்றும் செயல்திறனை நோக்கி நகர்கிறது. வயதான விவசாய மக்கள் தொகை மற்றும் அதிகரித்து வரும் தொழிலாளர் பற்றாக்குறையுடன், "ஒரு நபர், ஒரு இயந்திரம்" என்ற கருத்து பெரிய, பரந்த வேலை செய்யும் கருவிகளுக்கான தேவையை அதிகரிக்கிறது. சந்தை போக்குகள் சிறிய 3-மீட்டர் சுழலும் உழவு இயந்திரங்களிலிருந்து 9LH-12 போன்ற அகல-நீள மாதிரிகளுக்கு மாறி வருகின்றன, இது மூன்று சிறிய இயந்திரங்களின் செயல்பாட்டுத் திறனை வழங்குகிறது.

மேலும், "சுத்தமான தீவனம்" மீது அதிகரித்து வரும் முக்கியத்துவம் உள்ளது. கொரிய பால் பண்ணை ஊட்டச்சத்து நிபுணர்கள் சிலேஜின் சாம்பல் உள்ளடக்கம் குறித்து அதிகளவில் கடுமையாகி வருகின்றனர். பாரம்பரிய சக்கர ரேக்குகள் பெரும்பாலும் தரையைத் துடைத்து, வைக்கோல் மண் மாசுபடுவதற்கு வழிவகுக்கிறது. 9LH-12 இன் கிடைமட்ட செயல்பாடு, சரிசெய்யக்கூடிய உயர அமைப்புகளுடன் இணைந்து, விவசாயிகள் மண் மேற்பரப்பிற்கு மேலே ரேக் டைன்களை நிறுத்தி, அழுக்கு கலக்காமல் தீவனத்தை மட்டுமே சேகரிக்க அனுமதிக்கிறது. இது "கிடைமட்ட ரேக்குகள்" க்கான தேடல்களை அதிகரிக்கும் உலகளாவிய போக்குடன் ஒத்துப்போகிறது, இது வேலை வேகத்தைப் போலவே தீவன தரமும் முக்கியமானதாகக் கருதப்படும் முதிர்ச்சியடைந்த சந்தையை பிரதிபலிக்கிறது.

5. ஒழுங்குமுறை இணக்கம்: கொரிய மற்றும் சர்வதேச பாதுகாப்பு தரநிலைகள்

இறக்குமதி மற்றும் செயல்பாட்டிற்கு விவசாய இயந்திரங்களின் சட்டபூர்வமான நிலப்பரப்பை வழிநடத்துவது மிகவும் முக்கியமானது. 9LH-12 சீன தேசிய தரநிலையை கண்டிப்பாக கடைபிடிக்கும் வகையில் தயாரிக்கப்படுகிறது, ஆனால் மிக முக்கியமாக, தென் கொரியாவிற்கு ஏற்றுமதி செய்வதற்கான கடுமையான பாதுகாப்புத் தேவைகளைப் பூர்த்தி செய்யும் வகையில் இது வடிவமைக்கப்பட்டுள்ளது.

போக்குவரத்து விதிமுறைகள்: தென் கொரியாவில், இழுத்துச் செல்லப்படும் கருவிகளின் அகலம் குறித்து சாலைப் போக்குவரத்துச் சட்டம் கண்டிப்பானது. 9LH-12 ஒரு அதிநவீன நீளமான போக்குவரத்து முறையைக் கொண்டுள்ளது. அதன் செயல்பாட்டு அகலம் 12 மீட்டர் என்றாலும், இது 9.4 மீ நீளம் x 3.4 மீ அகலம் x 1.75 மீ உயரம் கொண்ட போக்குவரத்து பரிமாணத்திற்கு மறுகட்டமைக்கப்படுகிறது. மாகாண சாலைகளில் பரந்த சுமைகளுக்கு உள்ளூர் குறிப்பிட்ட அனுமதிகளை ஆபரேட்டர்கள் சரிபார்க்க வேண்டும், மேலும் கொரிய போக்குவரத்து பாதுகாப்பு ஆணையத்தால் (TS2020 தரநிலைகள்) தேவைப்படும் கட்டாய பிரதிபலிப்பு அடையாளங்கள் மற்றும் லைட்டிங் கருவிகளுக்கான பொருத்துதல் புள்ளிகளுடன் அலகு பொருத்தப்பட்டுள்ளது.

செயல்பாட்டு பாதுகாப்பு: போக்குவரத்தின் போது திடீர் சொட்டுகளைத் தடுக்க ஹைட்ராலிக் அமைப்புகளில் காசோலை வால்வுகள் உள்ளன, இது ஐரோப்பிய மற்றும் கொரிய இயந்திர உத்தரவுகளின் கீழ் ஒரு தேவையாகும்.

6. பிராண்ட் இணக்கத்தன்மை மற்றும் கூறு இடைமுகம்

| கணினி கூறு | விவரக்குறிப்பு / தரநிலை | இணக்கமான டிராக்டர் பிராண்டுகள் (கொரியா/உலகளாவிய) |

|---|---|---|

| ஹைட்ராலிக் அமைப்பு | இரட்டை ஹைட்ராலிக் ரிமோட் வால்வுகள் (1/2″ ISO 5675 குறிப்புகள்) | எல்எஸ் டிராக்டர் (எம்டி தொடர்), டேடோங் (கியோட்டி), டிஒய்எம், குபோடா, ஜான் டீர் |

| டிராபார் ஹிட்ச் | நிலையான விவசாய கிளீவிஸ் / பின் ஹிட்ச் | அனைத்து பயன்பாட்டு டிராக்டர்களுக்கும் யுனிவர்சல் ஃபிட் 35HP+ |

| டயர்கள் | விவசாய கருவி டயர்கள் | நிலையான மையங்கள் உள்ளூர் கொரிய டயர் பிராண்டுகளுடன் (ஹான்கூக், கும்ஹோ விவசாய வரிகள்) மாற்ற அனுமதிக்கின்றன. |

7. வாடிக்கையாளர் வெற்றிக் கதை: சுங்சியோங்னாம்-டோவில் செயல்திறன் ஆதாயங்கள்

தென் கொரியாவிலிருந்து வாடிக்கையாளர் மதிப்புரை

"நாங்கள் ஜியோல்லானம்-டோவில் ஒரு பெரிய அளவிலான பண்ணையில் செயல்படுகிறோம், மேலும் 9LH-12 கிடைமட்ட வைக்கோல் ரேக் மிகப்பெரிய மாற்றத்தை ஏற்படுத்தியுள்ளது. அதன் 12-மீட்டர் வேலை அகலத்துடன், நாங்கள் அதிக நிலத்தை விரைவாக மூட முடியும், எரிபொருள் செலவுகளைக் குறைக்கிறது மற்றும் மண் சுருக்கத்தைக் குறைக்கிறது. காற்றோட்டமான ஜன்னல்களை உருவாக்கும் இயந்திரத்தின் திறன், குறிப்பாக மழைக்காலங்களில், எங்கள் விரைவான உலர்த்தும் தேவைகளுக்கு மிகவும் முக்கியமானது."ஜப்பானில் இருந்து வாடிக்கையாளர் மதிப்புரை

"ஹொக்கைடோவில் உள்ள எனது குடும்ப பண்ணையில் ஒரு வருடமாக நான் 9LH-12 ஐப் பயன்படுத்தி வருகிறேன், வைக்கோல் ரேக்கைப் பார்த்து நான் ஒருபோதும் இவ்வளவு ஈர்க்கப்பட்டதில்லை. வடிவமைப்பு மிகவும் திறமையானது, மேலும் ஹைட்ராலிக் அமைப்பு தேவைப்படும்போது ரேக்குகளைத் தூக்குவதை மிகவும் எளிதாக்குகிறது. இது எங்கள் வயல்களுக்கு ஏற்றது, எங்கள் நேரத்தையும் உழைப்பையும் மிச்சப்படுத்துகிறது."ஆஸ்திரேலியாவிலிருந்து வாடிக்கையாளர் மதிப்புரை

"நியூ சவுத் வேல்ஸில் உள்ள எங்கள் பெரிய கால்நடைப் பண்ணையில், எங்கள் அனைத்து மேய்ச்சல் நில மேலாண்மைக்கும் 9LH-12 கிடைமட்ட வைக்கோல் ரேக்கைப் பயன்படுத்துகிறோம். 12 மீட்டர் அகலம் அதை நம்பமுடியாத அளவிற்கு திறமையானதாக்குகிறது, மேலும் கிடைமட்ட ரேக்கிங் நடவடிக்கை புல் மீது மிகவும் மென்மையாக இருக்கும். இந்த ரேக் ஒரு கேம்-சேஞ்சராக இருந்து வருகிறது, குறிப்பாக எங்கள் வறண்ட வானிலை நிலைமைகளுக்கு."அமெரிக்காவிலிருந்து வாடிக்கையாளர் மதிப்புரை

"சமீபத்தில் கலிபோர்னியாவில் எங்கள் அறுவடை நடவடிக்கைகளில் 9LH-12 ஐ ஒருங்கிணைத்துள்ளோம். இது கொண்டு வரும் வேகம் மற்றும் செயல்திறன் ஒப்பிடமுடியாதது. இந்த ரேக் அனைத்து வகையான தீவனங்களையும் எளிதாகக் கையாளுகிறது மற்றும் விரைவான பேலிங்கிற்காக வேகமாக உலரும் பஞ்சுபோன்ற, நன்கு காற்றோட்டமான ஜன்னல்களை உருவாக்கும் அற்புதமான வேலையைச் செய்கிறது."ரஷ்யாவிலிருந்து வாடிக்கையாளர் மதிப்புரை

"சைபீரியாவில், வானிலை கடுமையாகவும், நிலப்பரப்பு சீரற்றதாகவும் இருக்கும் இடத்தில், 9LH-12 கிடைமட்ட வைக்கோல் ரேக் அதன் மதிப்பை நிரூபித்துள்ளது. இது மிகவும் குளிரான சூழ்நிலையிலும் கூட நமது பரந்த மேய்ச்சல் நிலங்களை நன்றாகக் கையாளுகிறது. ஹைட்ராலிக் அமைப்பு எளிதான கட்டுப்பாட்டை அனுமதிக்கிறது, மேலும் ரேக்கின் வலுவான வடிவமைப்பு சவாலைப் பொருட்படுத்தாமல் அது தொடர்ந்து செயல்படுவதை உறுதி செய்கிறது."நியூசிலாந்திலிருந்து வாடிக்கையாளர் மதிப்புரை

"தெற்கு தீவில் உள்ள எங்கள் ஆடு பண்ணையில் இரண்டு பருவங்களுக்கும் மேலாக 9LH-12 ஐப் பயன்படுத்தி வருகிறோம். 12 மீட்டர் வேலை அகலம் எங்கள் வயல்களை முன்பை விட மிக வேகமாக சுத்தம் செய்ய அனுமதிக்கிறது. ரேக்கின் வடிவமைப்பு குறைந்தபட்ச வைக்கோல் இழப்பை உறுதி செய்கிறது, மேலும் முதல் முறையாக பயனர்களுக்கு கூட இதை இயக்குவது எளிது."கஜகஸ்தானிலிருந்து வாடிக்கையாளர் மதிப்புரை

"கஜகஸ்தானில், 9LH-12 எங்கள் செயல்பாடுகளுக்கு ஒரு அற்புதமான கூடுதலாக உள்ளது. பெரிய, தட்டையான மேய்ச்சல் நிலங்களில் திறமையாக ரேக் செய்யும் இயந்திரத்தின் திறன் ஒப்பிடமுடியாதது. ஹைட்ராலிக் லிஃப்ட் அமைப்பு தடைகளை அகற்றுவதை எளிதாக்குகிறது, மேலும் இயந்திரம் எங்கள் கரடுமுரடான நிலப்பரப்பைத் தாங்கும் வகையில் கட்டமைக்கப்பட்டுள்ளது."

8. 9YG-1.25A ரவுண்ட் பேலர் விற்பனைக்குப் பிந்தைய உத்தரவாதம் மற்றும் ஆதரவு அமைப்பு.

1. உதிரி பாகங்கள் பழுது மற்றும் மாற்றீடு.

2. ஒவ்வொரு தயாரிப்புக்கும் இலவச பயனர் கையேடு வழங்கப்படுகிறது.

3. விற்பனைக்குப் பிந்தைய சேவை மற்றும் உத்தரவாதம்/பராமரிப்பு.

4. உலகளவில் வழங்கப்படும் தயாரிப்புகள்.

5. தொழில்முறை மொழி குழுக்கள் உங்கள் தேவைகளைப் புரிந்துகொள்ள தொடர்பு கொள்கின்றன.

6. தயாரிப்பு பயிற்சி.

7. ஒவ்வொரு ஆண்டும் புல் வெட்டும் பருவத்தில், எங்கள் தயாரிப்புகளை வாங்கிப் பயன்படுத்திய ஒவ்வொரு மேய்ப்பருக்கும் நாங்கள் பின்தொடர்தல்கள் மற்றும் சந்தை ஆய்வுகளை நடத்துகிறோம், மேலும் முதல் முறையாகப் பயன்படுத்துபவர்களுக்கு தொழில்நுட்பப் பயிற்சியையும் வழங்குகிறோம்.

9. தொடர்புடைய கூறுகள்.

"வட்ட பேலர்களுக்கான ஷாஃப்ட் காலர்" அல்லது "வைக்கோல் பேலருக்கான மாற்று ஷாஃப்ட் காலர்" ஆகியவற்றைத் தேடுபவர்களுக்கு, எங்கள் தீர்வு நிலையான விவசாயத்திற்குத் தேவையான துல்லியத்தையும் நம்பகத்தன்மையையும் வழங்குகிறது.

நாங்கள் உதிரி பாகங்களையும் வழங்குகிறோம், அவற்றுள்: PTO ஷாஃப்ட் & டிராக்டர் கியர்பாக்ஸ், டிரைவ் செயின் & ஸ்ப்ராக்கெட், ஷீவ் & புல்லி, பிக்கப் ஷாஃப்ட் பேரிங்ஸ் & ஷாஃப்ட் காலர், வைக்கோல் பிக்கர் ஷாஃப்ட் & வைக்கோல் பிக்கர் ஸ்டாண்ட், ஸ்கிட்ஸ் & அப்ரேஷன் பிளேட்ஸ், பற்கள் & வைக்கோல் பிக்கர் ஸ்பிரிங்ஸ்.

எங்களைத் தொடர்பு கொள்ளுங்கள், நாங்கள் உங்களுக்கு விரிவான PDF ஐ பதிவிறக்கவும் கிடைக்கக்கூடிய மாற்று பாகங்கள்.

10. அடிக்கடி கேட்கப்படும் கேள்விகள் (FAQ)

கேள்வி 1. 9LH-12 கிடைமட்ட வைக்கோல் ரேக், கொரியாவில் பொதுவாகப் பயன்படுத்தப்படும் நிலையான LS டிராக்டருடன் இணக்கமாக உள்ளதா?

A1. ஆம், நிச்சயமாக. 9LH-12 25-44 kW (35-60 HP) மட்டுமே மின் உள்ளீடு தேவைப்படும் வகையில் வடிவமைக்கப்பட்டுள்ளது. கொரியாவில் காணப்படும் பயன்பாட்டு வகுப்பில் உள்ள பெரும்பாலான நிலையான LS டிராக்டர்கள் இந்த வரம்பிற்குள் சரியாக வருகின்றன. உங்கள் டிராக்டரில் லிஃப்டை இயக்க டிராபார் மற்றும் பின்புற ஹைட்ராலிக் ரிமோட்டுகள் இருக்கும் வரை, அது முழுமையாக இணக்கமாக இருக்கும்.

கேள்வி 2. உலர்த்தும் வேகத்தின் அடிப்படையில், கிடைமட்ட ரேக்கிங் செயல் சுழலும் வைக்கோல் ரேக்குடன் எவ்வாறு ஒப்பிடுகிறது?

A2. கிடைமட்ட நடவடிக்கை உலர்த்துவதற்கு சிறந்தது. வைக்கோலை இறுக்கமாக திருப்பக்கூடிய சில சுழலும் ரேக்குகளைப் போலல்லாமல், 9LH-12 வைக்கோலை பஞ்சுபோன்ற, காற்றோட்டமான காற்றோட்டமான காற்றோட்டமான பாதையில் துடைக்கிறது. இந்த அமைப்பு காற்றை பயிர் வழியாக மிகவும் திறம்பட செல்ல அனுமதிக்கிறது, இது ஈரப்பதமான கொரிய அறுவடை காலங்களில் ஈரப்பதத்தை விரைவாகக் குறைப்பதற்கு மிகவும் முக்கியமானது.

கேள்வி 3. இந்த 12 மீட்டர் ரேக்கை பூசன் துறைமுகத்திற்கு அனுப்புவதற்கான தோராயமான விலை அல்லது செலவு என்ன?

A3. கப்பல் செலவு தற்போதைய கடல் சரக்கு கட்டணங்கள் மற்றும் ஆர்டர் செய்யப்பட்ட அளவைப் பொறுத்தது. இருப்பினும், 9LH-12 ஒரு போக்குவரத்து முறையைக் கொண்டுள்ளது, இதில் நீளம் 9.4 மீ மற்றும் அகலம் 3.4 மீ ஆகும். நாங்கள் வழக்கமாக இவற்றை 40 அடி கொள்கலன்களில் அனுப்புகிறோம். இன்றைய கட்டணங்களின் அடிப்படையில் துல்லியமான CIF பூசன் விலைக்கு கீழே உள்ள “விலைப்பட்டியலைப் பெறுங்கள்” பொத்தானைப் பயன்படுத்தவும்.

கேள்வி 4. எனது குறிப்பிட்ட சுற்று பேலரின் பிக்அப்பிற்கு ஏற்றவாறு விண்ட்ரோவின் அகலத்தை சரிசெய்ய முடியுமா?

A4. ஆம், விண்ட்ரோ அளவு ஆபரேட்டரால் கட்டுப்படுத்தப்படுகிறது. பயண வேகத்தையும் ரேக்கின் ஈடுபாட்டையும் சரிசெய்வதன் மூலம், விண்ட்ரோவில் வைக்கோலின் அளவை நீங்கள் நிர்வகிக்கலாம். இது உங்கள் சுற்று அல்லது சதுர பேலரின் பிக்அப் அகலம் மற்றும் அடர்த்தி திறனுடன் பொருந்தக்கூடிய வகையில் வெளியீட்டை குறிப்பாக வடிவமைக்க உங்களை அனுமதிக்கிறது.

கேள்வி 5. சிலேஜில் மண் மாசுபடுவதைத் தவிர்க்க எந்த வகையான வைக்கோல் ரேக்குகள் சிறந்தவை?

A5. கிடைமட்ட மற்றும் இணையான பார் வைக்கோல் ரேக்குகள் பொதுவாக மண்ணைத் தவிர்ப்பதில் சக்கர ரேக்குகளை விட சிறந்தவை. 9LH-12 தரைக்கு சற்று மேலே சறுக்கி, அழுக்கை சொறிந்து விடாமல் புல்லை சேகரிக்கும் வகையில் டைன் உயரத்தை அமைக்க உங்களை அனுமதிக்கிறது. இது உங்கள் இறுதி சிலேஜ் பேல்களில் சாம்பல் உள்ளடக்கத்தை கணிசமாகக் குறைக்கிறது.

கேள்வி 6. பருவத்தின் போது 9LH-12 உடைந்தால், அதற்கான மாற்று டைன்கள் அல்லது பாகங்களை நான் எங்கே காணலாம்?

A6. ஒவ்வொரு இயந்திர வாங்குதலுடனும் ஒரு உதிரி பாகங்கள் தொகுப்பை நாங்கள் வழங்குகிறோம். நீண்ட கால பராமரிப்புக்காக, நாங்கள் நிலையான விவசாய கூறுகளைப் பயன்படுத்துகிறோம். சில நாட்களுக்குள் கொரியாவிற்கு எக்ஸ்பிரஸ் கூரியர் மூலம் பாகங்களை நாங்கள் அனுப்ப முடியும், அல்லது உங்கள் மாகாணத்தில் கிடைத்தால் எங்கள் உள்ளூர் அங்கீகரிக்கப்பட்ட விநியோகஸ்தர்களிடம் நீங்கள் சரிபார்க்கலாம்.

கேள்வி 7. இந்த இயந்திரத்திற்கு PTO இணைப்பு தேவையா, அல்லது அது தரையிலிருந்து இயக்கப்படுகிறதா அல்லது ஹைட்ராலிக் ஆக இருக்கிறதா?

A7. தனிப்பயனாக்கத்தின் போது தேர்ந்தெடுக்கப்பட்ட குறிப்பிட்ட உள்ளமைவைப் பொறுத்து ரேக்கிங் பொறிமுறையானது பொதுவாக தரையால் இயக்கப்படுகிறது அல்லது ஹைட்ராலிகல் உதவியுடன் செய்யப்படுகிறது. இருப்பினும், ரேக் கைகளைத் தூக்குவதற்கும் நிலைநிறுத்துவதற்கும் முதன்மைக் கட்டுப்பாடு உங்கள் டிராக்டரின் ஹைட்ராலிக் அமைப்பைச் சார்ந்துள்ளது, PTO ஷாஃப்டை அல்ல, இது எரிபொருள் நுகர்வு மற்றும் டிரைவ் லைனில் பராமரிப்பைக் குறைக்கிறது.

கேள்வி 8. தென் கொரியாவில் பொது சாலைகளில் இந்த அகலமான இயந்திரத்தை எவ்வாறு பாதுகாப்பாக கொண்டு செல்வது?

A8. இந்த இயந்திரம் 3.4 மீட்டர் அகலம் கொண்ட "போக்குவரத்து நிலை"க்கு மாறுகிறது. இது வேலை செய்யும் அகலத்தை விடக் குறுகலாக இருந்தாலும், அது இன்னும் அகலமான சுமையாகும். டிராக்டருடன் சரியான மெதுவாக நகரும் வாகன அடையாளங்கள் மற்றும் ஒளிரும் விளக்குகள் இணைக்கப்பட்டுள்ளதா என்பதை நீங்கள் உறுதி செய்ய வேண்டும். குறிப்பிட்ட நெடுஞ்சாலைகளில் பரந்த விவசாய சுமைகளுக்கான அனுமதிகள் குறித்து உள்ளூர் போலீசாரிடம் சரிபார்க்க பரிந்துரைக்கிறோம்.

கேள்வி 9. இந்த ரேக் பச்சை நறுக்கு சிலேஜ் போன்ற கனமான ஈரமான பயிர்களுக்கு ஏற்றதா அல்லது உலர்ந்த வைக்கோலுக்கு மட்டும் பொருத்தமானதா?

A9. 9LH-12 ஈரமான சிலேஜுக்கு (பச்சை சாப்) போதுமான அளவு உறுதியானது. அதிக ஈரப்பதம் கொண்ட பயிர்களின் கூடுதல் எடையைக் கையாள வடிவமைக்கப்பட்ட அதிக வலிமை கொண்ட ஸ்பிரிங் ஸ்டீலால் டைன்கள் தயாரிக்கப்படுகின்றன. இருப்பினும், மிகவும் கனமான ஈரமான பயிர்களுக்கு, சுத்தமான துடைப்பு மற்றும் சீரான விண்ட்ரோ உருவாக்கத்தை உறுதிசெய்ய சற்று மெதுவான வேகத்தில் இயக்க பரிந்துரைக்கிறோம்.

கேள்வி 10. மலைப்பாங்கான நிலப்பரப்பில் ஒரு அறுக்கும் இயந்திர ரேக்கின் பின்னால் இந்த ஏக்கர் பரப்பளவை இழுக்க தேவையான குறைந்தபட்ச குதிரைத்திறன் என்ன?

A10. குறைந்தபட்ச விவரக்குறிப்பு 35 HP ஆக இருந்தாலும், கொரியாவின் சில பகுதிகளில் பொதுவாக மலைப்பாங்கான பகுதிகளுக்கு, குறைந்தபட்சம் 50 HP டிராக்டரைப் பயன்படுத்த பரிந்துரைக்கிறோம். இயந்திரம் 1510 கிலோ எடையுள்ளதாக இருக்கும், எனவே 50HP டிராக்டரின் கூடுதல் எடை மற்றும் சக்தி, ரேக்கை மேலும் கீழும் சரிவுகளில் இழுக்கும்போது சிறந்த இழுவை மற்றும் நிலைத்தன்மையை வழங்கும்.