تفصیل

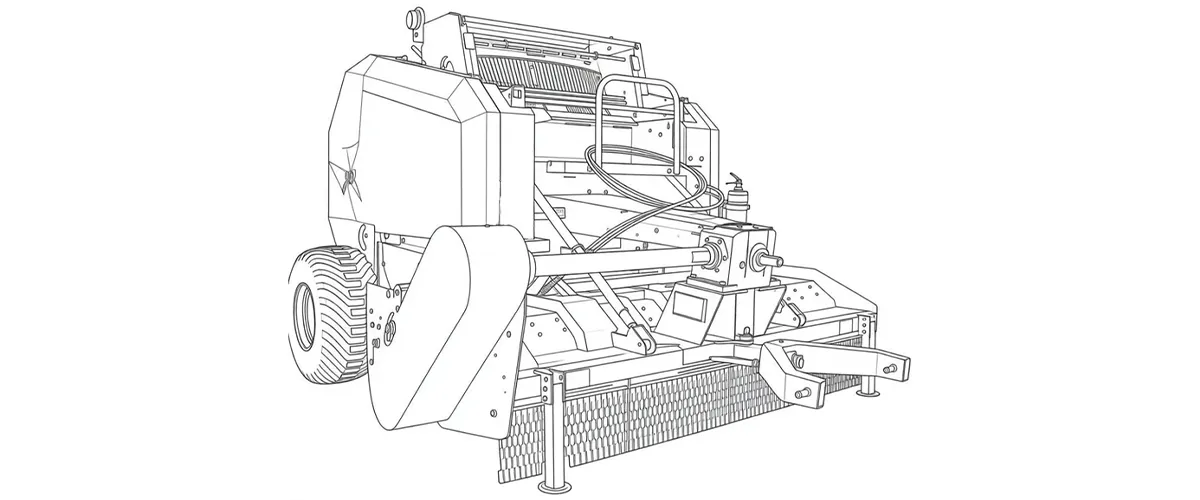

1. تکنیکی وضاحتیں: 9YG-1.0C سیریز

| نہیں | آئٹم | یونٹ | تفصیلات |

|---|---|---|---|

| 1 | ماڈل کا نام | / | 9YG-1.0C قسم گول بیلر |

| 2 | ہچ کی قسم | / | ٹریلڈ |

| 3 | پک اپ چوڑائی | ملی میٹر | 2400 |

| 4 | پک اپ میکانزم کی قسم | / | رولر کی قسم |

| 5 | Inlet میکانزم کی قسم | / | فلیل قسم + پش اور پل سسٹم |

| 6 | پک اپ چیمبر کا سائز | ملی میٹر | 1250 |

| 7 | پک اپ چیمبر قطر | ملی میٹر | 1000 |

| 8 | رولر ورک پیس شمار | ٹکڑے | 16 (فائل قسم) |

| 9 | رولر پریشر قطر | ملی میٹر | Φ222 |

| 10 | پک اپ کی قسم | / | میش قسم |

| 11 | مطلوبہ طاقت | Kw/hp | ≥69.8/95 |

| 12 | مشین کا وزن | کلو | 3198 |

| 13 | آؤٹ پٹ شافٹ کی رفتار | r/min | 540 |

| 14 | بیرونی طول و عرض (L × W × H) | ملی میٹر | 3800 × 2850 × 2200 (کام کرنے کی حالت) |

| 15 | گھاس کی کثافت کنٹرول | / | سینسر کنٹرول |

| 16 | گھاس کا سائز (لمبائی × چوڑائی) | ملی میٹر | Φ1000 × 1250 |

| 17 | گھاس کی کثافت | kg/m³ | 115-200 |

| 18 | پیداواری صلاحیت | ریک/h | 40-100 |

| 19 | وہیل قطر | ملی میٹر | 2100 |

| 20 | آپریٹنگ سپیڈ | کلومیٹر فی گھنٹہ | 5-20 |

| 21 | پک اپ چوڑائی | m | 2000 × 1.25 میٹر/گٹھری |

2. 9YG-1.0C گول بیلر: اعلی کثافت مکئی اور سائیلج بیلنگ کا حتمی حل

3. انجینئرنگ ایکسی لینس: مکینکس، مواد، اور درخواست کے منظرنامے۔

4. عالمی ریگولیٹری تعمیل: حفاظت، اخراج، اور زمین کا انتظام

5. ٹریکٹر اور اجزاء کی مطابقت

| سسٹم / اجزاء | مطابقت کی تفصیلات |

|---|---|

| ٹریکٹر برانڈز (کوریا/عالمی) | LS Mtron (XP Series)، TYM (T1003)، Daedong/Kioti (HX Series)، John Deere (6M سیریز) کے ساتھ ہم آہنگ۔ 95HP+ کی ضرورت ہے۔ |

| ہائیڈرولک آؤٹ پٹ | پک اپ لفٹ اور ٹیل گیٹ آپریشن کے لیے پیچھے والے ریموٹ ہائیڈرولک والوز (ڈبل ایکٹنگ) کے 2 سیٹ درکار ہیں۔ |

| بائنڈنگ میٹریل | معیاری 1230mm یا 1250mm نیٹ ریپ۔ Tama، Novatex، اور عام "راؤنڈ بیلر برانڈز" نیٹنگ کے ساتھ ہم آہنگ۔ |

| پی ٹی او کنکشن | معیاری 1-3/8″ 6-اسپلائن شافٹ۔ تنگ موڑ کے لیے وائڈ اینگل سی وی جوائنٹ شامل ہے (اختیاری)۔ |

* ڈس کلیمر: اوپر ذکر کردہ دیگر برانڈ نام صرف اور صرف تمثیلی مقاصد کے لیے فراہم کیے گئے ہیں۔ ہم ان برانڈ ناموں والی اصل مصنوعات یا آلات پیش نہیں کرتے ہیں۔

6. مارکیٹ کے رجحانات: ہائی ڈینسٹی سائیلج اور بایوماس کی طرف تبدیلی

7. کسٹمر کی کامیابی کی کہانی:

کلائنٹ 1 پروفائل: جنوبی کوریائی ڈیری فارمر

کسٹمر کے جائزے:

"ہم کئی مہینوں سے 9YG-1.0C راؤنڈ بیلر استعمال کر رہے ہیں، اور یہ ہمارے لیے گیم چینجر ثابت ہوا ہے۔ ہتھوڑے کے پنجوں کو اٹھانے کا نظام معمول کے بند ہونے والے مسائل کے بغیر چاول کے گیلے بھوسے کو سنبھالنا آسان بناتا ہے۔ گٹھری کی کثافت بہترین ہے، اور ہم اب سائیلج تیار کر سکتے ہیں جو موسم سرما میں کھانا کھلانے کے لیے بہترین ہے۔ مشین بہت زیادہ محنت کرنے کی سفارش کرتی ہے، اور یہ ہمارے لیے بہت زیادہ محنت کی تجویز کرتی ہے۔ ہر ایک کے لیے جس کو قابل اعتماد، اعلیٰ صلاحیت والے بیلر کی ضرورت ہو۔

کلائنٹ2 پروفائل: امریکی زرعی آلات کا ڈیلر

کسٹمر کے جائزے:

"امریکہ میں ایک ڈیلر کے طور پر، ہم نے مڈویسٹ میں اپنے صارفین کو کئی 9YG-1.0C راؤنڈ بیلرز فروخت کیے ہیں۔ فیڈ بیک بہت زیادہ مثبت رہا ہے۔ کاشتکار اس کی استعداد کو سراہتے ہیں - خشک گھاس سے لے کر سائیلج کی پیداوار تک۔ پائیداری اور کم دیکھ بھال کے اخراجات نے اسے ان لوگوں کے لیے ایک اعلیٰ انتخاب بنا دیا ہے جو قابل اعتماد، اعلی قیمت کے ساتھ اچھی طرح سے کام کرنے والی مشین کی تلاش میں ہیں۔ فصلیں اور سخت، ریشے دار باقیات جیسے مکئی کے ڈنٹھل۔"

کلائنٹ 3 پروفائل: آسٹریلیائی کیٹل فارمر

کسٹمر کے جائزے:

"9YG-1.0C راؤنڈ بیلر کے استعمال سے ہماری سائیلج کی پیداوار میں بہت زیادہ بہتری آئی ہے۔ یہ ہمارے اعلی کثافت والے مکئی کے سٹور کو آسانی سے سنبھالتا ہے اور مستقل طور پر سخت گانٹھیں تیار کرتا ہے جو ہمارے مویشیوں کے لئے بہترین ہیں۔ ایندھن کی کارکردگی ایک اور نمایاں خصوصیت ہے - ہم نے اپنے پچھلے بیلر کے ڈیزائن کے مقابلے میں ایندھن کی کھپت کو کم کرنے میں نمایاں کمی دیکھی ہے۔ کمپیکشن، جو ہماری زمین کی طویل مدتی صحت کے لیے ضروری ہے۔"

کلائنٹ 4 پروفائل: جنوبی کوریائی چاول کے بھوسے پروسیسر

کسٹمر کے جائزے:

"ہم ایک ایسے خطے میں کام کرتے ہیں جہاں گیلے موسم کے شروع ہونے سے پہلے چاول کے بھوسے کو تیزی سے پروسیس کرنے کی ضرورت ہوتی ہے، اور 9YG-1.0C کام کے لیے بہترین ہے۔ اس کا نیم جبری فیڈنگ سسٹم اور خودکار نیٹ بائنڈنگ فیچر ہمیں بغیر کسی مسئلہ کے چاول کے بھوسے کی بڑی مقدار کو ہینڈل کرنے کی اجازت دیتا ہے۔ مشین چلانے اور برقرار رکھنے میں آسان ہے، اور اس نے اپنے بہترین نتائج حاصل کیے ہیں، اور ہم نے اس کے بہترین نتائج حاصل کیے ہیں۔ موثر."

کلائنٹ 5 پروفائل: یورپی زرعی مشینری درآمد کنندہ

کسٹمر کے جائزے:

"ہم ایک سال سے زیادہ عرصے سے یورپ میں 9YG-1.0C راؤنڈ بیلر درآمد اور فروخت کر رہے ہیں، اور اس کا ردعمل لاجواب رہا ہے۔ مشین مضبوط ہے، پھر بھی چھوٹے زمینی پلاٹوں والے خطوں میں فٹ ہونے کے لیے کافی کمپیکٹ ہے۔ ساحلی علاقوں کے کسان، خاص طور پر، بیلر کی سنکنرن مزاحمت کو سراہتے ہیں۔ یہ اس کے استعمال کے لیے بہترین اور مثالی ہے، اور اس کے لیے آسان اور آسان ہے۔ پائیداری اور اعلی پیداوری کے خواہاں کسانوں کے لیے دیکھ بھال اسے ایک بہترین سرمایہ کاری بناتی ہے۔

8. 9YG-1.25A راؤنڈ بیلر فروخت کے بعد کی گارنٹی اور سپورٹ سسٹم۔

1. اسپیئر پارٹس کی مرمت اور تبدیلی۔

2. ہر پروڈکٹ مفت صارف دستی کے ساتھ آتی ہے۔

3. فروخت کے بعد سروس اور وارنٹی/مینٹیننس۔

4. عالمی سطح پر فراہم کردہ مصنوعات۔

5. پیشہ ورانہ زبان کی ٹیمیں آپ کی ضروریات کو سمجھنے کے لیے بات چیت کرتی ہیں۔

6. مصنوعات کی تربیت.

7. ہر سال گھاس کاٹنے کے موسم کے دوران، ہم ہر اس چرواہے کے لیے فالو اپ اور مارکیٹ سروے کرتے ہیں جس نے ہماری مصنوعات خریدی اور استعمال کی ہیں، اور پہلی بار استعمال کرنے والوں کو تکنیکی تربیت فراہم کرتے ہیں۔

9. 9YG-1.25A راؤنڈ بیلر فروخت کے بعد کی گارنٹی اور سپورٹ سسٹم۔

ہم نے اپنے جدید پیداواری اڈوں کو جدید آلات سے لیس کیا ہے، جیسے:

·ISO9001 کوالٹی مینجمنٹ سسٹم سرٹیفیکیشن

CNC لیزر کاٹنے والی مشینیں۔

لیزر اور پلازما کاٹنے کے نظام

· خودکار اسمبلی لائنز

الیکٹروسٹیٹک چھڑکاو پیداوار لائنوں کے نظام

· ڈیجیٹل فیکٹری اور صنعتی سافٹ ویئر

· ڈائنومیٹر ٹیسٹنگ اسٹیشنز وغیرہ

ہمارے بارے میں

10. متعلقہ اجزاء۔

ان لوگوں کے لیے جو "متبادل اجزاء ہیے بیلر" کی تلاش کر رہے ہیں، ہمارا حل پائیدار کاشتکاری کے لیے درکار درستگی اور قابل اعتمادی فراہم کرتا ہے۔

ہم اسپیئر پارٹس بھی پیش کرتے ہیں، بشمول PTO شافٹ اور ٹریکٹر گیئر باکس، ڈرائیو چین اور سپروکیٹ، شیو اینڈ پللی، پک اپ شافٹ بیئرنگز اور شافٹ کالر، ہی پککر شافٹ اور ہی پیکر اسٹینڈ، سکڈز اور ابریشن پلیٹس، دانت اور گھاس چننے والے اسپرنگس۔

ہم سے رابطہ کریں، اور ہم آپ کو تفصیلی بھیجیں گے۔ پی ڈی ایف دستیاب متبادل حصوں کی.

اکثر پوچھے گئے سوالات (FAQ)

Q1۔ 9YG-1.0C راؤنڈ بیلر کی تخمینی قیمت کتنی ہے بشمول بوسان، جنوبی کوریا کو بھیجنا؟

A1۔ FOB قیمت خام مال کی لاگت اور حسب ضرورت کی بنیاد پر مختلف ہوتی ہے۔ ایک درست CIF بسان کوٹ کے لیے جس میں شپنگ اور انشورنس شامل ہیں، براہ کرم ہماری سیلز ٹیم سے براہ راست "ایک اقتباس حاصل کریں" بٹن کے ذریعے رابطہ کریں۔

Q2. کیا یہ ہیوی ڈیوٹی بیلر چیمبر کو بند کیے بغیر سائیلج کے لیے مکئی کے گیلے ڈنڈوں کو سنبھال سکتا ہے؟

A2۔ بالکل۔ 9YG-1.0C خاص طور پر سائیلج راؤنڈ بیلر کے طور پر ڈیزائن کیا گیا ہے۔ اس کا ہتھوڑا پنجہ اٹھانا اور نیم زبردستی کھانا کھلانے کا نظام فعال طور پر گیلے مواد کو چیمبر میں دھکیلتا ہے، معیاری گھاس بیلرز میں عام ہونے والے بندوں کو روکتا ہے۔

Q3. پہاڑی علاقوں میں 9YG-1.0C کو موثر طریقے سے چلانے کے لیے کس ٹریکٹر ہارس پاور کی سختی سے ضرورت ہے؟

A3۔ جب کہ کم از کم ضرورت 95 HP ہے، پہاڑی خطوں کے لیے جیسا کہ Gangwon-do میں، ہم کم از کم 105-110 HP والے ٹریکٹر کی تجویز کرتے ہیں تاکہ لوڈ کے نیچے محفوظ ٹونگ اور مستقل PTO پاور مینٹیننس کو یقینی بنایا جا سکے۔

Q4. دیکھ بھال کے اخراجات اور حصوں کے لحاظ سے 9YG-1.0C کا موازنہ ورمیر راؤنڈ بیلر سے کیسے ہوتا ہے؟

A4۔ 9YG-1.0C پریمیم برانڈز جیسے Vermeer کے مقابلے کی پائیداری پیش کرتا ہے لیکن پرزوں کی قیمتوں میں نمایاں طور پر کم ہے۔ ہم معیاری زنجیر کے سائز اور بیرنگ استعمال کرتے ہیں، جس سے دیکھ بھال سستی ہو جاتی ہے اور حصوں کو عالمی سطح پر منبع کرنا آسان ہوتا ہے۔

Q5. کیا اس مشین کو خشک الفالفا کی کٹائی کے لیے میرے قریب فروخت کے لیے گھاس بیلر کے طور پر استعمال کرنا ممکن ہے؟

A5۔ جی ہاں، معیاری ٹائن پک اپ کے لیے ہتھوڑے کے پنجوں کے پک اپ کو تبدیل کرنے سے، یہ مشین اعلیٰ صلاحیت والے خشک گھاس بیلر کے طور پر کام کرتی ہے، اور زیادہ کثافت کو برقرار رکھتے ہوئے نازک الفالفا کے پتوں کا نرمی سے علاج کرتی ہے۔

Q6. مجھے ایک قابل اعتماد بیلر مینوفیکچرر کہاں سے مل سکتا ہے جو میری ڈیلرشپ کے لیے OEM برانڈنگ پیش کرتا ہے؟

A6۔ ایور پاور ایک پریمیئر بیلر مینوفیکچرر ہے جو مکمل OEM خدمات پیش کرتا ہے۔ ہم مشین کو آپ کے برانڈ کے رنگوں میں پینٹ کر سکتے ہیں (مثال کے طور پر، جان ڈیری سبز یا کبوٹا اورنج) اور آپ کے ڈیکلز کو آپ کی پروڈکٹ لائن میں بغیر کسی رکاوٹ کے اضافے کے لیے لاگو کر سکتے ہیں۔

Q7. 9YG-1.0C کس قسم کا نیٹ ریپ استعمال کرتا ہے، اور کیا یہ کورین مارکیٹ میں دستیاب ہے؟

A7۔ یہ معیاری 1230 ملی میٹر یا 1250 ملی میٹر چوڑا نیٹ ریپ استعمال کرتا ہے۔ یہ سائز ایک عالمگیر معیار ہے اور پورے جنوبی کوریا اور بین الاقوامی منڈیوں میں زرعی سپلائرز سے وسیع پیمانے پر دستیاب ہے۔

Q8۔ ہتھوڑے کے پنجوں کا پک اپ چھوٹے گول بیلر پر معیاری ٹائن پک اپ سے کیسے مختلف ہے؟

A8۔ ایک معیاری ٹائن پک اپ ہلکی گھاس اٹھانے کے لیے تار کے دانت استعمال کرتا ہے۔ ہتھوڑا کلاؤ پک اپ مضبوط، فلیل نما پنجوں کا استعمال کرتا ہے جو بھاری، سخت مکئی کے ڈنٹھوں کو براہ راست زمین سے ٹکڑے ٹکڑے کرنے اور اٹھانے کے لیے ڈیزائن کیا گیا ہے، جو معیاری ٹائنوں کو پہنچنے والے نقصان کو روکتا ہے۔

Q9. کیا آپ درج کردہ راؤنڈ بیلر کی قیمت کے لیے تکنیکی مدد یا انسٹالیشن گائیڈ فراہم کرتے ہیں؟

A9۔ ہاں، راؤنڈ بیلر کی قیمت میں ایک جامع انگریزی دستی، ویڈیو انسٹالیشن گائیڈز، اور 24/7 آن لائن تکنیکی مدد شامل ہے تاکہ یہ یقینی بنایا جا سکے کہ آپ مشین کو اعتماد کے ساتھ سیٹ اپ اور چلا سکتے ہیں۔

Q10۔ کیا میں اس ہیوی ڈیوٹی ماڈل کے ساتھ ایک مکسڈ کنٹینر منی راؤنڈ بیلر کے ساتھ فروخت کے لیے آرڈر کر سکتا ہوں؟

A10۔ بالکل۔ ہم شپنگ کے اخراجات کو بہتر بنانے کے لیے مخلوط آرڈرز کی حوصلہ افزائی کرتے ہیں۔ آپ ہیوی ڈیوٹی 9YG-1.0C کو ہمارے منی راؤنڈ بیلر ماڈلز کے ساتھ جوڑ کر اپنی مارکیٹ میں مختلف کسٹمر سیگمنٹس کو پورا کر سکتے ہیں۔

ایڈیٹر: PXY