9YG-2.24D 圆捆打捆机 S9000

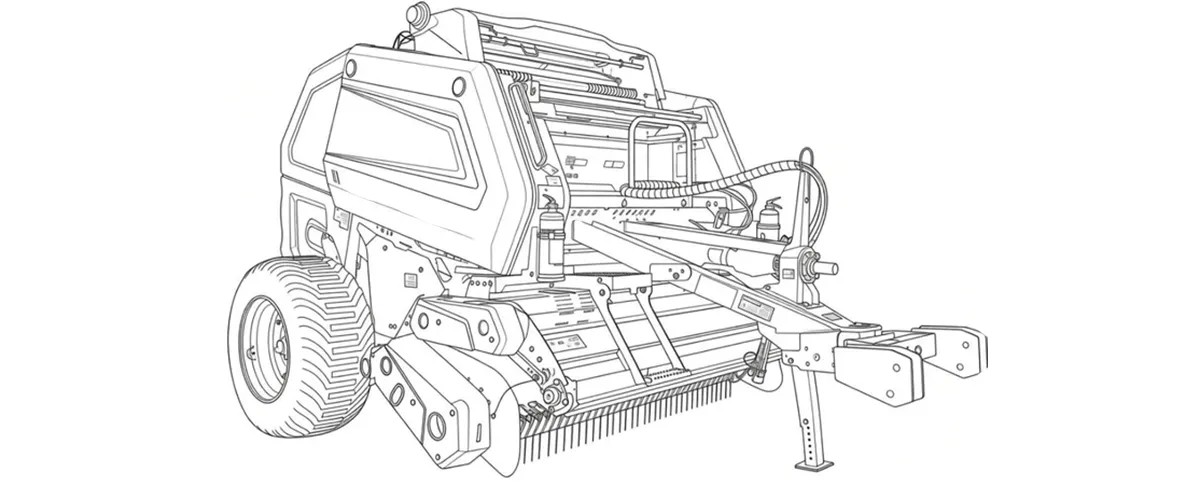

The 9YG-2.24D Round baler S9000 is a robust traction round baler designed to maximize efficiency in challenging field conditions. Unlike standard balers that struggle on slopes, the S9000 features an innovative adjustable traction device with a 1000nm torque capacity and a 30° lateral tilt limit. This design ensures continuous operation. Equipped with reinforced dual-side 20A heavy-duty chains, this net wrap baler delivers superior compression, producing high-density bales (up to 500kg).

1. Key selling points of the 9YG-2.24D Round baler S9000.

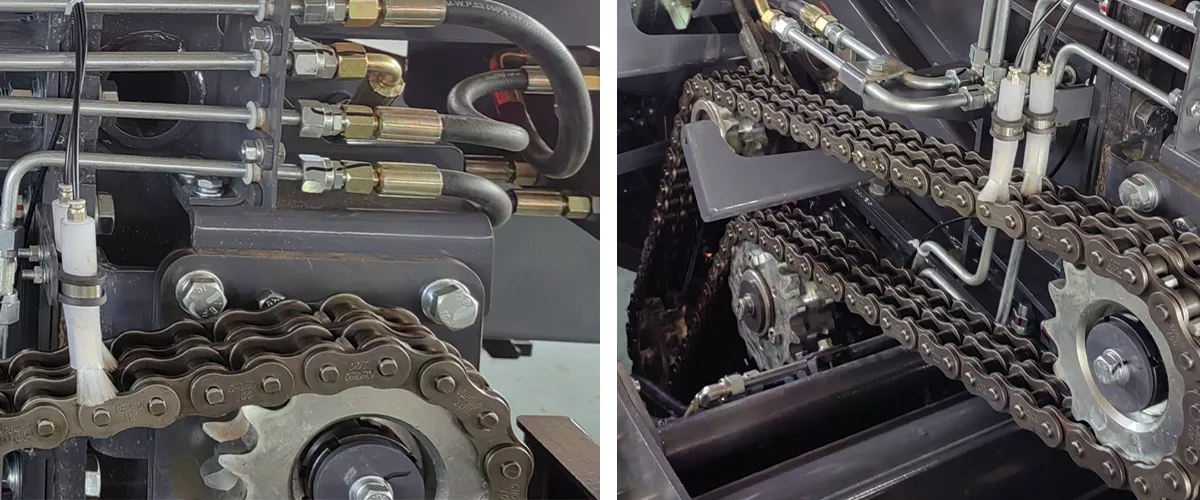

High-density baling: Employs double-sided 20A heavy-duty chains, allowing for single-bale weights of 250-500 kg.

Strong terrain adaptability: A new traction device supports 100° lateral turning and 30° tilt adjustment, solving the problem that existing traction-type round balers can only adjust horizontally within a certain range and cannot tilt.

Working efficiency: Highly efficient output of 40-100 bales/hour.

2.Why the 9YG-2.24D Round baler S9000 is Your Reliable Partner in the Field?

·Enhanced Compression for Heavier Bales

Technical highlights: The rear compartment has been upgraded to dual-sided 20A heavy-duty chains.

User benefits: Compared to ordinary chains, it offers stronger compression force and higher bale density (100-200 kg/m³), reducing waste in transportation and storage space.

·Superior Terrain Adaptability

Technical Highlights: A new traction device with a torque of 1000 Nm and adjustable tilt angle. Lateral steering range is 100°, with a tilt limit of 30°.

User Benefits: This product solves the problem of drive shaft damage caused by the traditional traction device's horizontal adjustment when turning on uneven or small plots of land. The ability to tilt the device at an angle helps protect the equipment.

·Efficient Pickup & Feeding System

Technical features: 2240mm wide pickup, toothed pickup + toothed roller + roller feed.

User benefits: Clean pickup, smooth feeding, maintains smooth operation even when handling coarse corn stalks, less prone to clogging, and the rear drum design creates loose inner and tight outer bales.

3.Technical Specifications of 9YG-2.24D-Round baler S9000.

| 不。 | 物品 | 单元 | 规格 |

|---|---|---|---|

| 1 | 型号名称 | / | 9YG-2.24D Round Baler (S9000) |

| 2 | 挂钩类型 | / | Traction |

| 3 | 拾音器宽度 | 毫米 | 2240 |

| 4 | Pickup Structure Type | / | Spring Tooth Type |

| 5 | Feeding Structure Type | / | Dial Tooth Roller + Drum Type |

| 6 | Compression Chamber Baling Mechanism Type | / | Roller Type |

| 7 | Compression Chamber Width | 毫米 | 1400 |

| 8 | Compression Chamber Diameter | 毫米 | Φ1200 |

| 9 | Number of Compressing Components | Piece | 18 (Rollers) |

| 10 | Compression Roller Diameter | 毫米 | Φ222 |

| 11 | Binding Method | / | Net Wrap |

| 12 | 匹配功率 | 千瓦 | 55-100 |

| 13 | 结构重量 | 公斤 | 4262 |

| 14 | PTO Speed | 转/分钟 | 720 |

| 15 | Overall Dimensions (L×W×H) | 毫米 | 4240×3010×2450 (Working State) |

| 16 | Bale Density Control | / | 传感器控制 |

| 17 | Bale Size (Diameter × Width) | 毫米 | Φ1300×1400 |

| 18 | Bale Density | kg/m³ | 100-200 |

| 19 | 生产率 | bales/h | 40-100 |

| 20 | Wheel Track | 毫米 | 2600 |

| 21 | 运行速度 | 公里/小时 | 5-35 |

| 22 | Binding Net Specification | 米 | 2000×1.4/Roll |

4.9YG-2.24D Round Baler S9000 directly addresses market demand.

Application Scenarios in Brazil

1. Sugarcane Straw Recovery (Sugarcane Straw Recovery / Palhiço da Cana)

Background: Brazil is the world's largest sugarcane producer (mainly concentrated in São Paulo state). With the widespread adoption of mechanized harvesting, large quantities of sugarcane leaves and tops (collectively known as straw) are left in the fields.

Pain Point: Sugar mills recover this straw for biomass power generation (cogeneration) or to produce second-generation ethanol (2G ethanol). However, sugarcane straw is coarse, stiff, and fluffy, making it extremely difficult to transport.

Advantages of the S9000 Series:

High-Density Baling: The S9000 series' dual-sided 20A heavy-duty chains provide exceptional compressive force. For fluffy sugarcane leaves, high-density bales are essential to reduce transportation costs. Our S9000 series perfectly meets this requirement.

Durability: Sugarcane fields often contain not only straw but also ratooning, and the ground is uneven. The S9000's 1000nm torque traction device and 30° tilt protection adapt to sugarcane field conditions, preventing drive shaft breakage.

2. Corn Stuff Utilization under the "ILPF" System (Integrated Crop-Livestock-Forestry)

Background: Brazil is vigorously promoting integrated agriculture, forestry, and animal husbandry. In Mato Grosso, a second crop of corn (Safrinha) is planted after soybean harvest.

Application: After corn harvest, the corn stalks left in the field are high-quality winter feed or bedding for beef cattle.

Advantages of the S9000 Series: Anti-clogging Feeding: Corn stalks are thick and hard, easily clogging ordinary balers. The S9000 series' "toothed roller + drum type" feeding structure is specifically designed for this coarse-fiber crop. The straw bin uses a roller type, allowing for smooth intake and output without jamming.

3. Haymaking in the Southern and Central Highlands

Background: The terrain in southern Brazil (e.g., Rio Grande do Sul) and the central highlands (e.g., Minas Gerais) is mostly hilly. Livestock farming is well-developed here, and in winter, the pasture withers and must be baled and stored as hay (such as Brachiaria and ryegrass) before the rainy season ends.

Application: Haymaking and baling on slopes.

Advantages of the S9000 Series: Terrain Conqueror: Pastures in Minas Gerais are often located on rolling hills. Traditional rigid-connected balers struggle here, while the S9000 series' adjustable traction system perfectly conforms to the ground, ensuring safe operation.

Among the S9000 series, the 9YG-2.24D-圆捆打捆机-Transcend is more recommended.

Application Scenarios in Korea

1. Rice Straw Collection and Its Use as Feed for Korean Cattle

Background: Rice is a staple food in the Korean market, and Korean beef is a vital industry. Rice straw is the primary source of roughage for Korean cattle (accounting for over 60%). Every year after the rice harvest in October and November, the straw must be quickly baled before snowfall.

Pain Points: Korean paddy fields are typically small, with many ridges, and can become muddy due to autumn rains. Ordinary balers are prone to damage to the drive shaft and slippage when frequently turning around and crossing ridges.

Advantages of the S9000 Series:

·King of Paddy Fields: The S9000's 1000nm torque traction device (100° steering, 30° tilt) is designed for these conditions. It protects the drive system when frequently turning around in narrow Korean paddy fields or crossing ridges with elevation differences—a crucial factor for Korean farmers: durability.

·Wide-width harvesting: 2240mm pickup width.

2. Winter Ryegrass Silage (Italian Ryegrass Silage)

Background: To utilize fallow fields during winter, large quantities of Italian ryegrass are planted in southern South Korea (Jeolla and Gyeongsang provinces) as a high-quality forage. This typically requires harvesting in spring when the moisture content is high, and then processing it into bale silage.

Pain Points: Silage requires extremely high density to expel air and prevent mold. If the machine's compression force is insufficient, the bales will be loose, causing the feed to spoil and resulting in significant losses.

Advantages of the S9000 Series:

High Density + High Quality: The S9000's dual-sided 20A heavy-duty chains provide compression force exceeding that of comparable products. It produces tightly packed, high-density silage bales, which, combined with the mesh bag system, effectively lock in moisture and nutrients.

3. Mountainous & Terraced Fields Operations

Background: 70% of South Korea is mountainous, and pastures and farmlands in regions like Gangwon Province are mostly located on hillsides or terraced fields.

Pain Points: Uneven ground is the norm. Rigidly connected balers are not only prone to damage when operating on slopes, but also risk tipping over.

Advantages of the S9000 Series:

30° Tilt Protection Safety Feature: When the tractor and baler are on different levels (e.g., the tractor is on the road and the baler is in the field; or when going uphill or downhill), the adjustable traction device ensures uninterrupted power transmission and prevents the machine from tipping over.

5.Customer Reviews and Case Studies of 9YG-2.24D Round Baler S9000.

Client1 Profile: Mongolia

用户评价:

"Our pastures are far from flat. We used to break drive shafts constantly with our old balers when turning on the slopes. The S9000's adjustable traction hitch is a lifesaver. It tilts and turns with the tractor without binding. Plus, the high-density bales are crucial for us to store enough hay for the harsh winter. A truly robust machine for us."

Client2 Profile: Mongolia

用户评价:

"Dealing with tough corn stalks requires a beast of a machine. Standard balers often clog or suffer chain failures. This round baler handles the coarse stalks. The feeding roller system is very aggressive and prevents blockages. It feels much heavier and durable than other balers we tried.To be honest, I prefer this one."

6. Application Scenarios of the 9YG-2.24D Round baler S9000

Ⅰ. Targeting hilly terrain and forage harvesting

Ⅱ. Targeting straw crops and transportation efficiency

Ⅲ. Targeting netting efficiency and forage preservation

Ⅳ. Targeting biomass energy and tropical agriculture

7. The farm-balers-9YG-2.24D Round baler S9000 after-sales guarantee and support system.

1. 备件维修和更换。

2. 每件产品都附带免费用户手册。

3. 售后服务和保修/维护。

4. 产品销往全球。

5. 专业语言团队沟通,了解您的需求。

6. 产品培训。

7. 每年割草季节,我们都会对所有购买和使用过我们产品的牧民进行后续跟进和市场调查,并为首次使用者提供技术培训。

8. The farm-balers-9YG-2.24D Round baler S9000 after-sales guarantee and support system.

我们为现代化生产基地配备了尖端设备,例如:

·ISO9001 Quality Management System Certification

·数控激光切割机

激光和等离子切割系统

·自动化装配线

·静电喷涂生产线系统

·数字化工厂和工业软件

·测功机测试站等等

关于我们

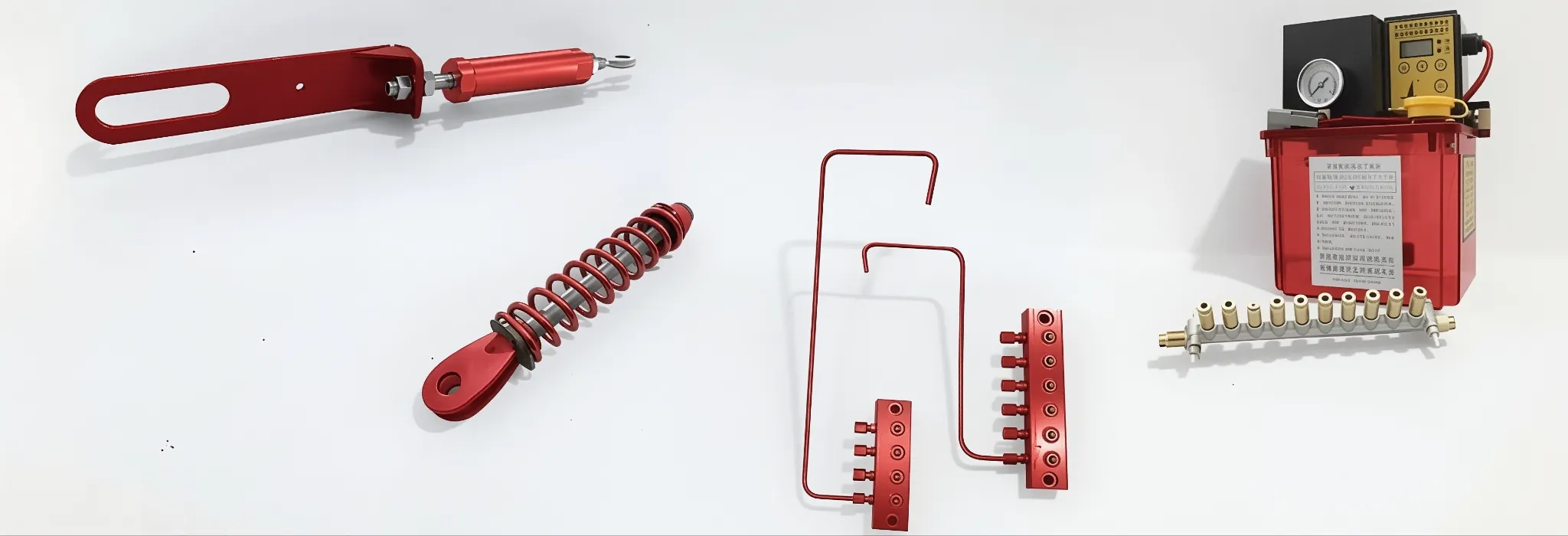

9.Related components.

Related components: Sprocket

For those searching for "Sprocket for round balers" or "replacement Sprocket for hay baler," our solution provides the precision and reliability needed for sustainable farming.

我们还提供备件,包括 PTO轴和拖拉机变速箱、驱动链和链轮、滑轮和皮带轮、拾禾器轴承和轴环、收草机轴和收草机支架、滑板和耐磨板、齿轮和收草机弹簧。

联系我们 我们会向您发送一份详细的 PDF 可用的替换零件。

常问问题:

Q1.What crops can the 9YG-2.24D S9000 handle?

A1.Crops that can be baled include wheat, rice, cotton, pasture, corn silage, alfalfa, sugarcane, and reeds.

Q2.How does the updated traction device improve durability?

The new traction device boasts a maximum torque of 1000 Nm. It features adjustable tilt angles: a lateral steering angle of 100° and a maximum tractor lateral tilt limit of 30°. This overcomes the limitation of existing towed round balers, where the traction device can only be adjusted horizontally within a certain range, lacking tilt angle adjustment. Our product ensures optimal work results and schedules for our customers.

When encountering uneven terrain in the field, the drawbar will not break due to forced twisting, which is crucial for operations in non-flat areas.

Q3.Why choose Net Wrapping over Twine?

A3.The S9000 uses net wrapping. Compared to hemp rope, net wrapping is faster, produces more regular bales, and is more resistant to rainwater penetration when stored outdoors, reducing forage loss.

Q4.What is the weight of the bale produced?

A4.Depending on the crop type and moisture, the bale weight typically ranges from 250kg to 500kg.

Q5.What other replacement parts do we provide?

A5.Our replacement parts include:

1. PTO shaft & agricultural gearbox assemblies

2. Chains & sprockets (heavy-duty roller chain drives)

3. Belts & pulleys/tensioning mechanism parts

4. Bearings, bearing housings, bushings & shaft locks

5. Wear parts for hay picking systems: spring teeth, hay picking shafts, slippers, wear plates, etc.

6. Knotting/wrapping system accessories: knotter gears, blades, friction plates, guide wheels, etc.

7. Baling chamber/compacting system accessories: rollers, roller sprockets, liners, pulleys, shafts, etc.

8. Hydraulic & control components: hydraulic cylinders, O-rings, hoses, control cables, and accessories.

编辑:PXY