描述

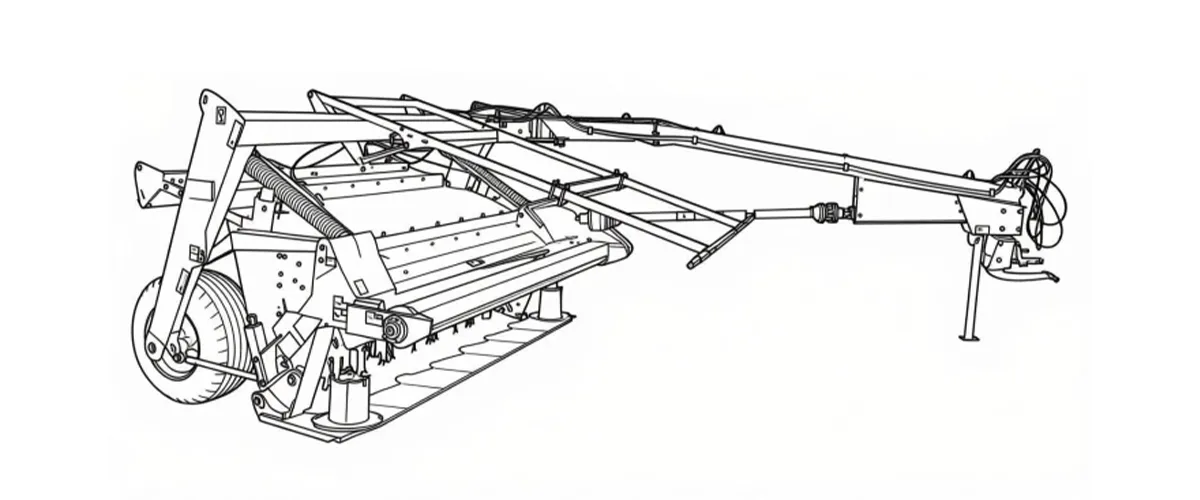

1. 技術規格:9GQY-3.2系列

| 不。 | 物品 | 單元 | 規格 |

|---|---|---|---|

| 1 | 型號名稱 | / | 9GQY-3.2型圓捆打捆機 |

| 2 | 掛鉤類型 | / | 側拉 |

| 3 | 切割寬度 | 米 | 3.2 |

| 4 | 切割器結構類型 | / | 旋轉 |

| 5 | 刀片數量 | 件 | 8 |

| 6 | 印刷類型 | / | 衝擊式圓盤壓機 |

| 7 | 拾音器寬度範圍 | 米 | 0.8-2.2 |

| 8 | 所需功率 | 千瓦/馬力 | ≥80.88/110 |

| 9 | 工作速度範圍 | 公里/小時 | 6-15 |

| 10 | 輸出軸轉速 | 轉/分鐘 | 540-1000 |

| 11 | 刀片數量 | 件 | 16 |

| 12 | 外部尺寸(長×寬×高) | 毫米 | 6750 × 3500 × 2000 |

| 13 | 平均切割高度 | 毫米 | ≥50 |

| 14 | 操作員數量 | 人 | 1 |

| 15 | 結構重量 | 公斤 | 2185 |

2. 主要事實與能力

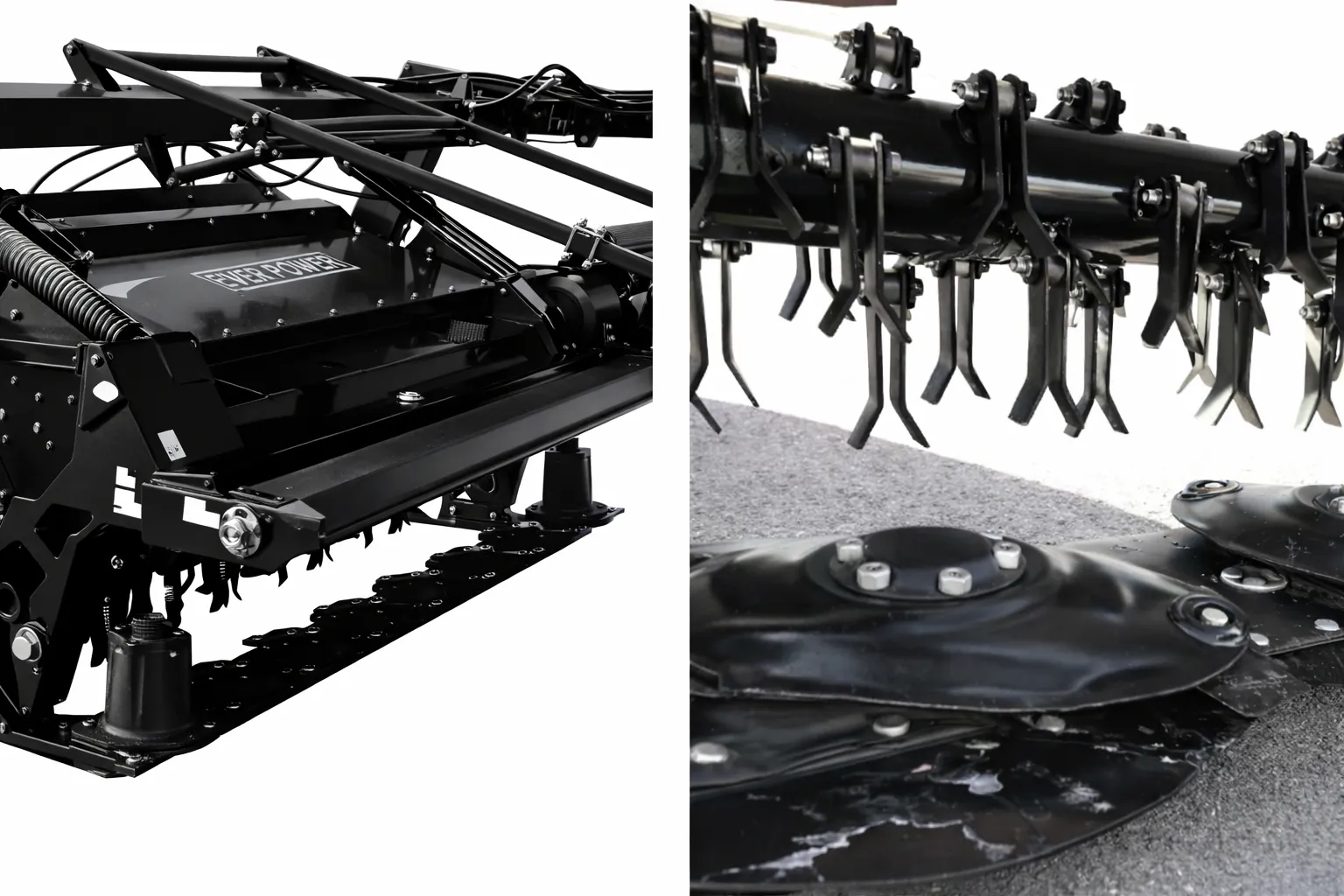

- 高效切割: 配備 8 個旋轉圓盤和 16 個空氣動力學刀片,可實現 3.2 公尺的乾淨切割,速度高達 15 公里/小時。

- 高階體能訓練: 採用錘擊式護髮素,可破壞莖部角質層,加速水分蒸發,對於潮濕氣候至關重要。

- 地形適應性: 獨立的雙懸吊系統確保切割桿能夠精確地跟隨地面輪廓,從而保護草坪。

- 安全機制: 液壓避障系統在清除障礙物後自動重置切割桿。

- 堅固耐用: 這款重型底盤重達 2185 公斤,可減少振動並確保高速運轉時的穩定性。

3. 革新牧草收割方式:9GQY-3.2 型割草壓扁機

4. 工程卓越:工作原理與冶金學

5. 法規遵循:機械安全與土地管理

操作像 9GQY-3.2 這樣的大型農業機械需要嚴格遵守安全和環保法規。

對於我們的合作夥伴 韓國這台機器的設計符合以下規定: 農業機械化促進法具體而言,側拉式設計包含一個液壓擺動機構,使該裝置能夠在公路運輸時直接與拖拉機後方對齊,從而減小寬度以滿足韓國的要求。 道路交通法 適用於農業機械。該機器配備標準安全反光標識和慢速車輛 (SMV) 標誌安裝點。動力輸出軸 (PTO) 採用符合 CE 標準的防護罩完全包裹,以防止纏繞,符合 ISO 4254-1(農業機械安全)標準。這種對安全的承諾對於保護操作人員和最大限度降低農場主的責任至關重要。

一個 土地管理視角9GQY-3.2 支持永續農業實踐。土壤壓實是全球關注的重大議題,許多國家都嚴格遵守「良好農業規範」(GAP)指南對其進行監管。 9GQY-3.2 透過使用寬大的浮動輪胎(通常為 400/60-15.5 或類似規格)來解決這個問題,這些輪胎將機器 2 噸的重量分散到更大的表面積上,從而最大限度地減少地面壓力。此外,「超級浮動保護」系統確保切割刀在土壤上滑動,而不是鑿入土壤。這可以防止草根結構(草皮)受損,促進草皮更快再生,以便進行下一次收割。在歐盟或亞洲受保護的濕地等土壤保護法律嚴格的地區,9GQY-3.2 能夠在不破壞土壤剖面的情況下收割蘆葦或牧草,使其成為土地管理者和承包商對環境負責的選擇。

6. 市場趨勢:整合式空調的轉變

全球牧草收割市場正經歷重大變革,從簡單的割草作業轉向集割草和調理於一體的綜合過程。在韓國,由於雨季導致乾草收割條件不穩定,乾草調理機和割草調理一體機的需求量較去年同期增加約251噸。農民逐漸意識到,調理節省的時間(通常可縮短一整天的乾燥時間)決定了最終產品的價值:是高價值、高品質的青貯飼料,還是發黴、低價值的飼料。

此外,市場也呈現出作業寬度不斷增加的趨勢。過去2.4公尺的機器是標準配置,但像9GQY-3.2這樣寬度超過3公尺的機型正逐漸成為新的主流,以匹配韓國合作社使用的現代拖拉機日益增長的馬力。市場也更傾向於使用甩刀式調理機而非滾筒式調理機來處理牧草,因為甩刀式調理機能更有效地去除牧草表面的蠟質層。

7. 曳引機和農具相容性

| 組件類別 | 相容性詳情 |

|---|---|

| 拖拉機馬力範圍 | 需≥110匹馬力(80.88千瓦)。相容於LS Mtron(XP/MT7系列)、TYM(T130)、約翰迪爾6M系列、久保田M6。 |

| 液壓系統 | 需要 2 套後部遠端閥(雙作用)用於升降控制和擺動式牽引桿操作。 |

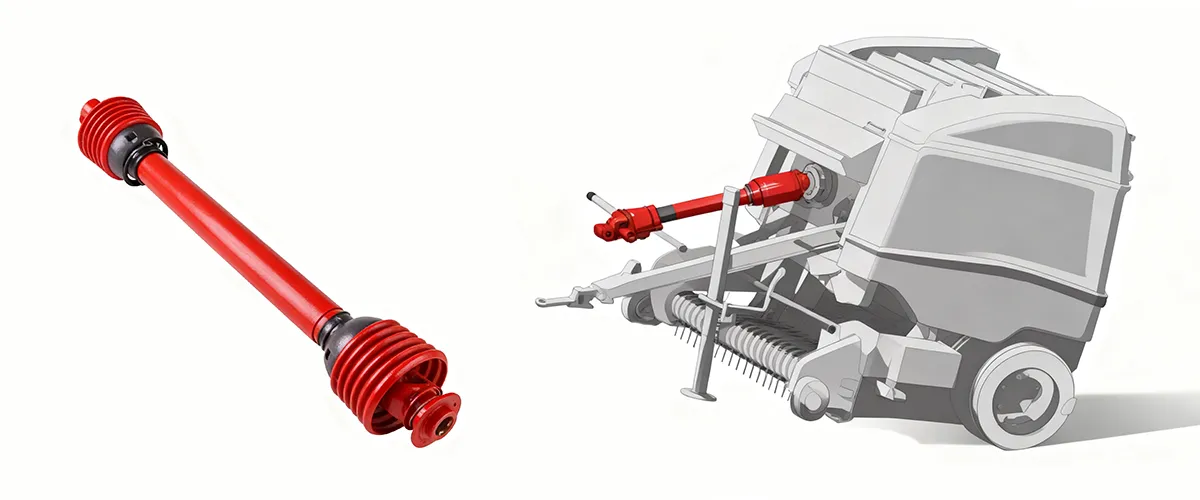

| PTO 連接 | 標準 1-3/8″ 6 齒或 21 齒花鍵軸。540/1000 RPM 可轉換輸入。 |

| 掛鉤類型 | 牽引桿/銷式掛鉤。適用於 II 類和 III 類牽引桿。 |

| 刀片更換 | 使用標準快換式或螺栓固定式扭曲刀片,相容於主要「乾草割草機壓扁機」售後市場零件。 |

*免責聲明:以上提及的其他品牌名稱僅供參考。我們不提供這些品牌名稱的原廠產品或設備。

8. 客戶成功案例:

9. 9YG-1.25A 圓捆機售後保固與支援系統。

1. 備件維修和更換。

2. 每件商品都附有免費使用手冊。

3. 售後服務和保固/維修。

4. 產品銷往全球。

5. 專業語言團隊溝通,了解您的需求。

6. 產品培訓。

7. 每年割草季節,我們都會對所有購買和使用過我們產品的牧民進行後續跟進和市場調查,並為首次使用者提供技術培訓。

10. 9YG-1.25A 圓捆機售後保固和支援體系。

我們為現代化生產基地配備了尖端設備,例如:

·ISO9001品質管理系統認證

·CNC雷射切割機

雷射和等離子切割系統

·自動化組裝線

·靜電噴塗生產線系統

·數位化工廠和工業軟體

·馬力機測試站等等

關於我們

11. 相關組件。

對於那些搜尋「圓捆機軸環」或「乾草捆機替換軸環」的人來說,我們的解決方案提供了永續農業所需的精度和可靠性。

我們也提供備件,包括 PTO軸和拖拉機變速箱、驅動鍊和鏈輪、滑輪和皮帶輪、拾禾器軸承和軸環、收草機軸和收草機支架、滑板和耐磨板、齒輪和收草機彈簧。

聯絡我們, 我們會寄給您一份詳細的 PDF 可用的替換零件。

12. 常見問題 (FAQ)

Q1. 運送到釜山港的9GQY-3.2型割草壓扁機的價格是多少?

A1. 價格取決於鋼材成本和運輸物流。如需包含報關單據的釜山到岸價 (CIF) 精確報價,請點擊「取得報價」按鈕直接聯絡我們的銷售團隊。

Q2. 9GQY-3.2 與約翰迪爾 630 Moco 相比,切割能力如何?

A2. 9GQY-3.2 的切割寬度與 JD 630 相似,均為 3.2 公尺(約 10 英尺 6 英吋),並採用類似的旋轉圓盤系統。雖然 JD 630 是一款傳奇機型,但我們的這款機型在處理能力和物料處理性能方面與之相近,價格卻更加親民。

Q3. 我可以在只有 90 匹馬力的拖拉機上使用這款待售的圓盤耙嗎?

A3. 我們強烈建議至少使用 110 匹馬力(80.88 千瓦)的拖拉機。雖然 90 匹馬力的拖拉機或許可以提升它,但在作物高產的情況下,它難以維持調節器和切割刀所需的動力輸出軸轉速,從而導致堵塞。

Q4. 這台機器適合收割高大的蘆葦或生質能源作物嗎?

A4. 是的,9GQY-3.2 是專為禾本科牧草和蘆葦設計的。旋轉圓盤可以輕鬆切割粗壯、纖維豐富的莖稈,而調理器則有助於將其分解,以便於後續加工。

Q5. 機器的乾草調理部分需要哪些維護?

A5. 日常維護包括檢查鏈輪齒的磨損或損壞情況,每運轉10小時潤滑一次轉子軸承,以及檢查傳動皮帶的張力。這是一款低維護設計。

Q6. 你們是否供應與紐荷蘭圓盤割草機型號相容的刀片等備件?

A6. 我們為9GQY系列提供全系列原廠備品。我們的葉片採用標準安裝尺寸,因此通常可以與主流品牌的通用售後配件互換。

Q7. 「超級漂浮保護裝置」在岩石地形上是如何運作的?

A7. 本系統採用液壓蓄壓器。當切割刀桿碰到岩石時,阻力壓力會觸發液壓系統,瞬間將切割刀桿抬升越過障礙物,然後再將其放下,從而防止刀盤受損。

Q8. 我可以調整不同打捆機取貨器的鋪條寬度嗎?

A8. 是的,後擋板是可調節的。您可以將條垛寬度設定為 0.8 公尺到 2.2 公尺之間,以配合您的圓捆機或方捆機的拾取寬度。

Q9. 您是打捆機製造商還是割草機供應商?

A9. EVER-POWER是一家綜合性農業機械製造商。我們生產割草機、耙草機和打捆機。我們可以提供完整的「農業打捆機銷售」套餐,包括割草機、耙草機和打捆機,為您提供完整的收割解決方案。

Q10. 客製化顏色的 OEM 訂單的最小起訂量 (MOQ) 是多少?

A10. 標準型產品我們可以單台出貨。如需完全客製化(例如,噴塗成綠色以配合您的約翰迪爾車隊),我們通常會要求至少訂購 3 台。

編輯:PXY